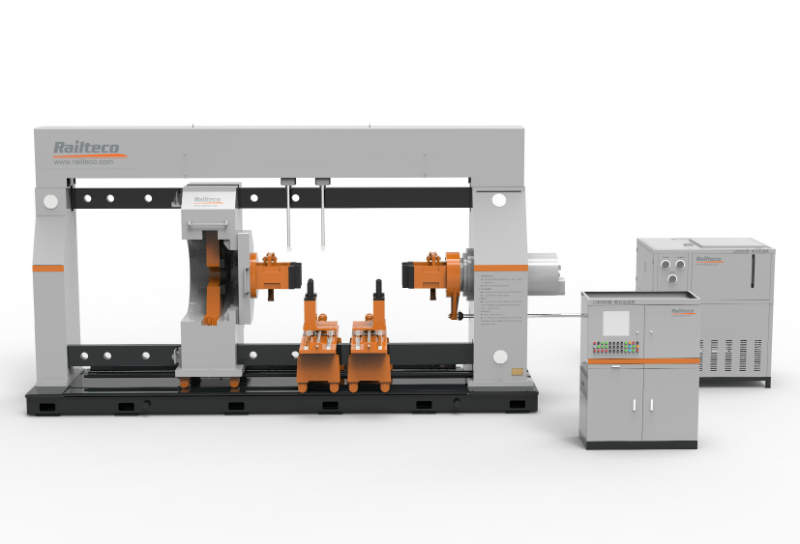

Type A Wheelset Press-Fitting Machine

Railteco’s Type A Wheelset Press-Fitting (Mounting, Assembly or Charging) Machine is used for unloading and assembling wheels, brake discs, and gear wheels.

It can be used on passenger cars, wagons, electric multiple units, and city rail vehicles.

It can also be used for wheelset anti-pressure test operations. Applicable to wheelsets with standard gauge, meter gauge and wide gauge.

The equipment is controlled by a microcomputer, which can automatically control and monitor the press-fitting process.

At the same time, it records and prints press-fit force curves and other press-fitting data.

Adopting laser measurement technology to better control press-fitting accuracy. Provide cloud-based remote data collection solutions to better serve users.

Main technical parameters include:

- Maximum press force: 3,000kN

- Main pressure head stroke: 800mm

- Applicable wheel diameter: φ700mm-φ1,250mm

- Applicable axle length: 1600mm-2550mm

- Max. fast forward and retreat speed of the main pressure head: 2,200mm/min

- Working speed of the main pressure head: 30mm-220mm/min

- Press-fitting accuracy (Inner Distance): <0.2mm

- Press-fitting accuracy (wheel position tolerance): <0.3mm

- Hydraulic system Max. working pressure: 26MPa

- Maximum forward speed of the measuring head: 1,000mm/min

- Supporting weight of wheel set support car: 4t

- Equipment total power: 27kW

- Net weight: about 27,000kg

- Overall dimension: 7,000mm×2,040mm×3,500mm