Bogie Workshop System

The Weighwell TrackCell™ Bogie Workshop System is purpose-built to improve quality control and weight distribution during bogie production, overhaul, and repair. Designed for seamless integration into both new and existing workshop infrastructure, it provides engineers with precise, repeatable measurements they can rely on.

Originally developed for installation beneath a bogie press, the TrackCell™ system can also be used to weigh individual axles, complete railcars, and locomotives. This flexibility makes it a valuable addition to any rail manufacturing or maintenance facility.

Seamless integration into your workshop

The TrackCell™ is permanently installed into the track, replacing standard rail sections with precision loadcells that weigh directly on the wheel tyre. This ensures consistent accuracy while maintaining track height. Installation can be completed in just a few hours, with minimal disruption to workshop operations.

Available in single-gauge or optional multi-gauge configurations, the system is suitable for workshops working with multiple rail vehicle types. An adjustable track section allows for different bogie lengths and wheel centre distances, making it a versatile choice for varied production requirements.

Accurate, real-time data

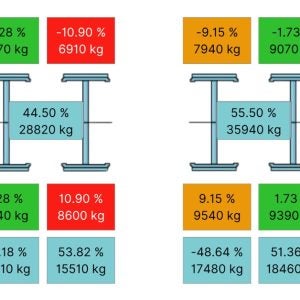

When paired with our static weighing interfaces, either a rugged digital indicator or PC-based software, the TrackCell™ delivers live readings for each wheel, axle, and bogie. This allows engineers to:

- Identify and correct imbalances during assembly or refurbishment

- Verify weight compliance before release to service

- Monitor quality standards consistently across multiple vehicles

By integrating accurate weighing into the workshop process, operators can reduce rework, improve ride quality, and ensure compliance with safety regulations.

Key benefits of our bogie workshop system

- Precision measurement – achievable accuracy of 0.2% with a track cell™ under each axle.

- Multi-gauge capability – optional configurations for workshops handling different track gauges

- Adaptable – adjustable sections to suit various bogie designs

- User-friendly interfaces – clear, real-time data via digital indicator or pc software

Engineered to fit your workshop

The track cell™ bogie workshop system is built for precision and durability, with each loadcell section measuring 502mm and capable of handling up to 15,000kg per wheel (higher capacities available if required). The system can be powered by either mains supply or battery, offering flexibility for different workshop setups.

Data can be transmitted via a wired connection up to 15 metres per axle or wirelessly up to 60 metres in urban environments. This robust design ensures accurate, repeatable results while fitting seamlessly into your existing workshop processes.

Key applications

- Rail bogie manufacturing facilities.

- Maintenance depots.

- Overhaul and refurbishment workshops.

Why choose Weighwell’s bogie workshop system?

Weighwell’s TrackCell™ system delivers the precision, reliability, and ease of use that modern workshops demand. Designed for long-term use, it helps you achieve accurate, repeatable results and streamline weighing operations across your facility.