Advanced High Performance Epoxy Adhesives Revolutionise Structural Bonding

Structural polymers offer distinct advantages over traditional fastening methods.

Master Bond manufacturers different types of adhesives for the railway industry, including silicone, epoxy, polyurethane, polysulfide, and UV cure systems.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Master Bond manufactures a wide range of epoxy, silicone, polyurethane, polysulfide, cyanoacrylate, and UV cure systems for the assembly of transportation equipment. Specific Master Bond grades include:

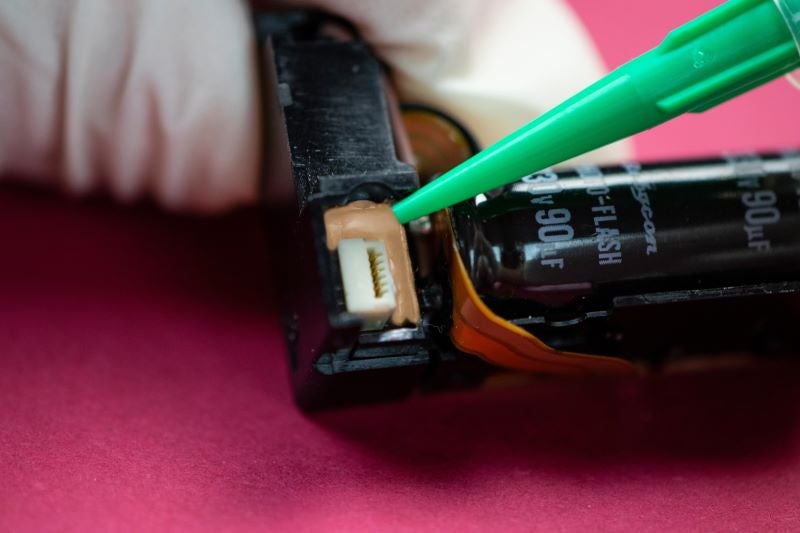

Master Bond’s vibration, shock, and impact-resistant bonding systems are designed to offer superior quality and long-term durability.

With a well-deserved reputation for superb performance upon exposure to hostile environmental conditions, our vibration, impact and shock resistant compounds are successfully employed in the transportation and railway industries. They are used in applications ranging from design and production to repair, maintenance and field service.

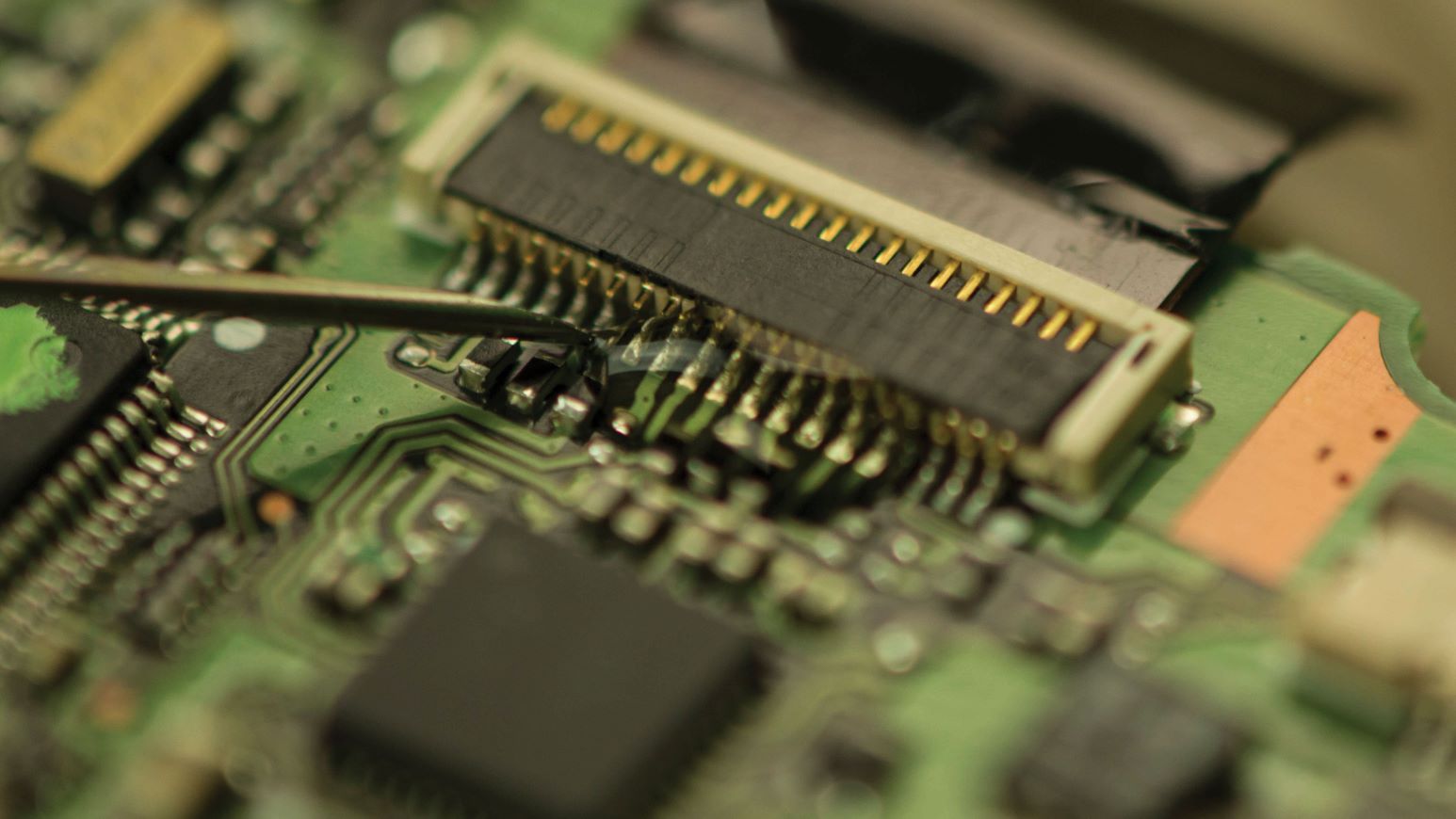

We offer systems with properties that enable them to be used in a wide variety of industry applications. Examples include electrical and thermal conductivity, chemical resistance, low shrinkage, optical clarity, abrasion resistance, fast curing, and gap-filling.

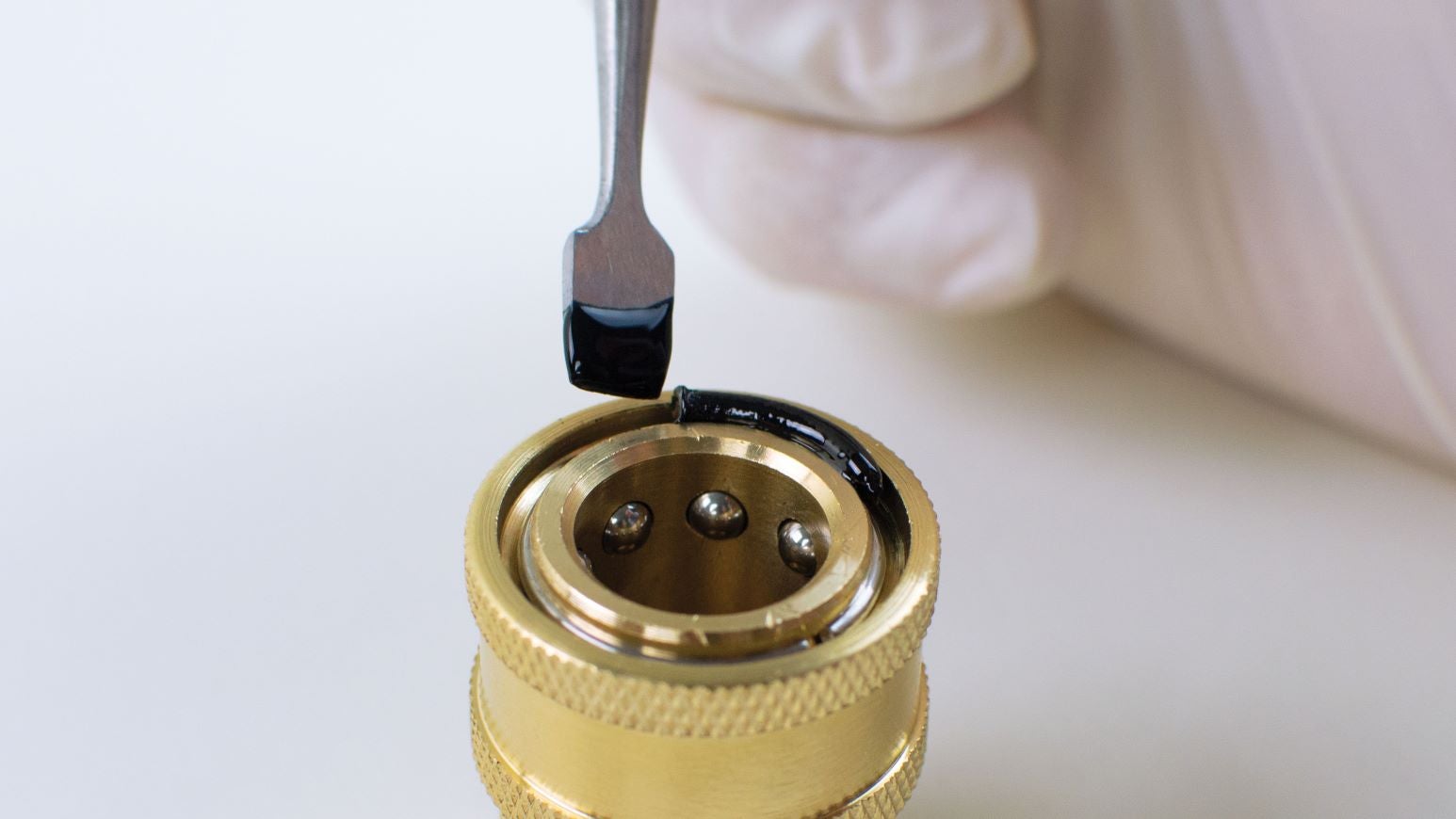

Epoxies are the most widely used polymeric materials for adhesives, sealants, coatings, pottings / encapsulations, and impregnants. Two-part systems can be cured at either room temperature or elevated temperatures.

Epoxies offer unique versatility in application and performance. Their most desirable properties include high bond strength to a wide variety of different substrates, outstanding gap-filling capabilities, excellent electrical insulation, high chemical inertness and exceptional resistance to shock and vibration.

Special formulations are available, including systems with thermal conductivity (electrically insulating) for heat dissipation, electrically conductive systems, systems for cryogenic applications, as well as systems with high performance in the most hostile environmental conditions. Viscosities and cure times can be tailored to meet specific application requirements.

One of our most popular products is Master Bond EP21TDCHT, a two-part epoxy with a convenient 1:1 mix ratio. Featuring high peel strength, it has excellent shock and vibration resistance and is serviceable from -100°F to 350°F.

EP51 is a fast-setting epoxy with long-term durability, high strength, and tough bonds that are remarkably resistant to thermal cycling and chemicals.

Another noteworthy adhesive, Supreme 10HT has a unique blend of performance properties — such as high shear and peel strengths — coupled with convenient handling with no mixing prior to use. It forms high-strength bonds serviceable over the wide temperature range of 4°F to 400°F.

As a toughened system, Supreme 10HT offers superior resistance to impact, thermal shock, vibration and stress fatigue cracking. Steelmaster 43HT is a high-performance, stainless-steel filled two-component epoxy resin system for the cost-effective repair, maintenance, rebuilding, restoring and resealing of worn or damaged metallic components. It is also an excellent adhesive for bonding carbide to steel in OEM or repair situations, particularly when high compressive strength is needed.

We offer a wide array of convenient packaging alternatives as well as easy application to speed productivity, minimize waste and save energy. These include:

Structural polymers offer distinct advantages over traditional fastening methods.

Because of its outstanding strength and other physical properties, Master Bond Supreme 10HT has been selected for use in several published research studies.

The system is electrically non-conductive and thermally insulative.

This epoxy has reliable electrical insulation properties, with a volume resistivity exceeding 1014 ohm-cm at 75°F.

Supreme 11AOHTLP cures at room temperature in two to three days, and faster with heat, in two to three hours at 200°F.

EP114 features excellent flow properties, with a mixed viscosity of 500-1,500 cps.

Supreme 17HTND-2 is thermally stable, featuring a high glass transition temperature (Tg) of 410°F (210°C).

Master Bond EP21LVFL combines good flexibility with a solid strength profile. It is curable at room temperature with a long working life of 120-160 minutes at 75°F for a 100g batch.

Supreme 42HT-2ND Black is electrically insulative, with a volume resistivity greater than 1014 ohm-cm.

Master Bond MasterSil 323AO-LO is a two component silicone elastomer with a self-priming feature, designed for bonding, sealing and gap filling applications. This electrically insulating and thermally conductive compound meets NASA low outgassing specifications and can be used in the aerospace, electronic, opto-electronic and specialty OEM industries.

Commercially available high temperature, thermally conductive epoxies, silicones, and (inorganic) ceramic adhesives were used in this study to bond carbon-carbon composites to commercially pure (CP) titanium sheets.

Serviceable from -100°F to +300°F, this toughened system resists thermal cycling, vibration, and shock.

EP17TF is a reliable electrical insulator, possessing a volume resistivity greater than 1015 ohm-cm.