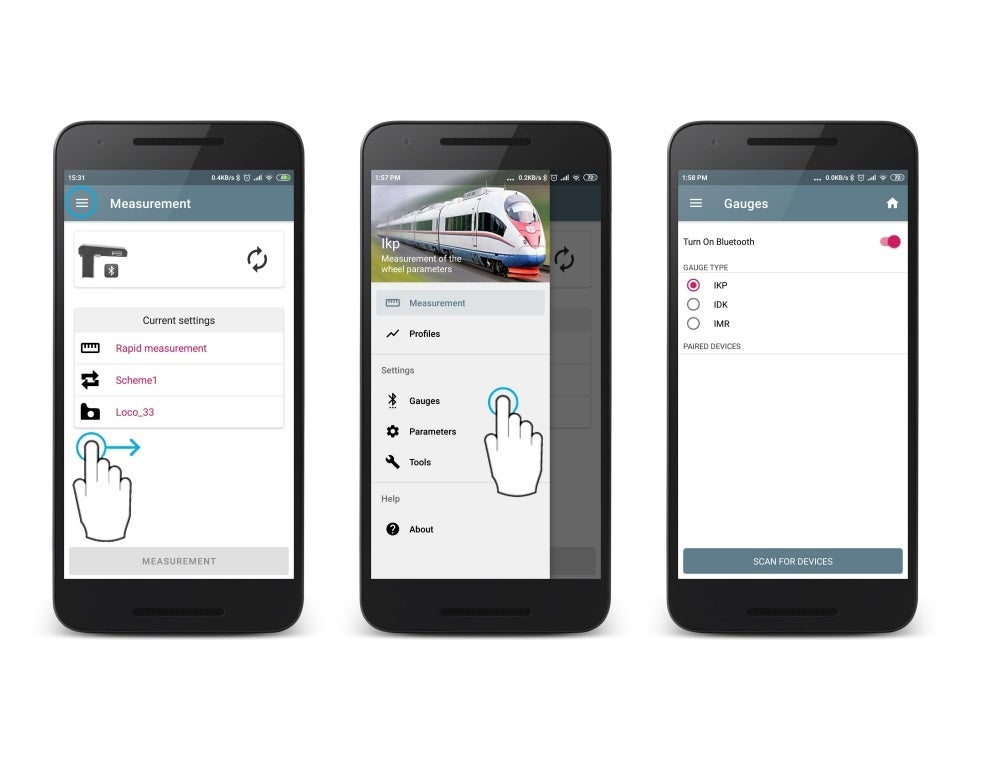

Android mobile application for wheelsets parameter measurement

The Android App is designed for working with hand-held devices for wheelsets parameter measurement.

RIFTEK produces a range of multifunctional rail and wheel measuring and control systems.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Scientific and production company RIFTEK EUROPE specialises in the development and fabrication of optoelectronic instruments for measuring geometrical quantities. The company offers integrated solutions for control and automation problems, from sensing devices to multifunctional rail and wheel measuring and control systems.

RIFTEK’s basic product line includes:

Sensors:

Instruments:

RIFTEK specialises in products for the railway industry, including:

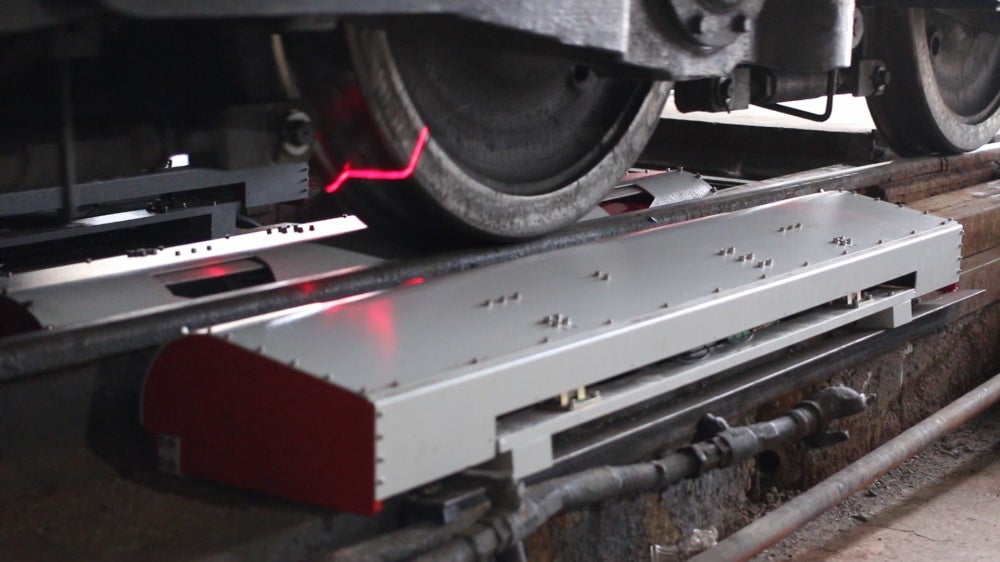

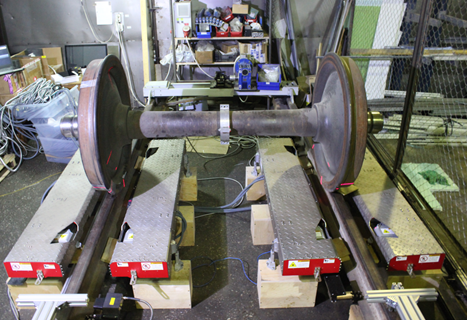

The 3DWheel system is designed for contactless, automatic measurement of geometrical parameters of railway wheels and uses a combination of 2D laser scanners, which are mounted wayside in the track area. The system can be easily installed at any type of rail infrastructure.

The system uses a combination of ten (fourteen for tramways carriages) RIFTEK special 2D laser scanners, RF627 Series mounted wayside in the track area (five/seven pieces for each track side) and calibrated into one common coordinate system. The measurement cycle starts when an inductive sensor detects a wheel. While the wheel passes through the system of synchronised 2D laser scanners, its profile is taken at many sections.

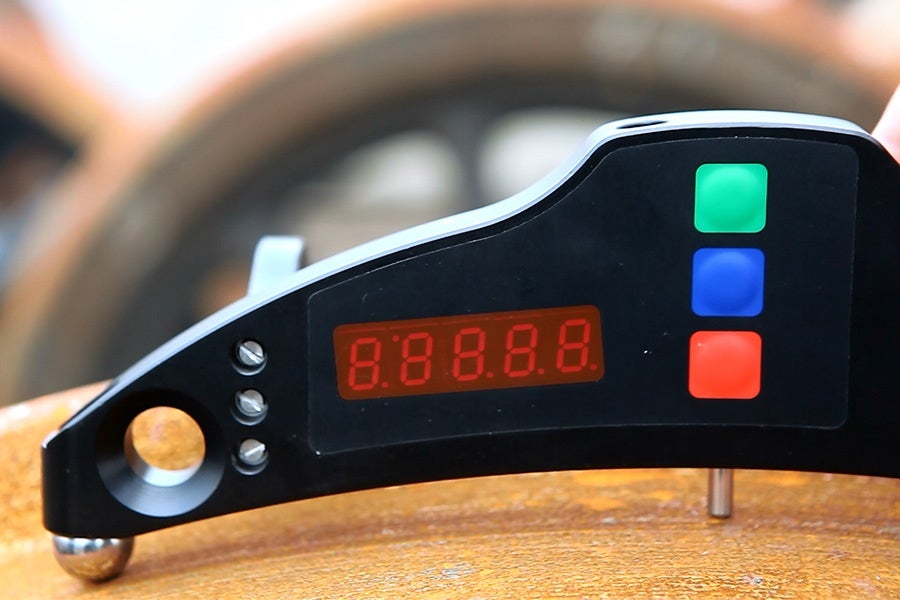

The electronic gauge is designed for measuring wheel rolling circle diameter.

Measurements are made directly from rolling stock without wheel set roll-out. The measurement of the diameter is performed according to the ‘three points’ technique, without complete wheel coverage.

The IDK gauge contains a numeric display to show the value of the wheel diameter. Additionally, the IDK-BT gauge additionally contains Bluetooth interface to transfer results into the wheel-set wear database management system.

The measurement method is based on the diameter calculation using the known length of the segment chord (the distance between the ball bearings centres), which is obtained when placing the gauge onto the wheel.

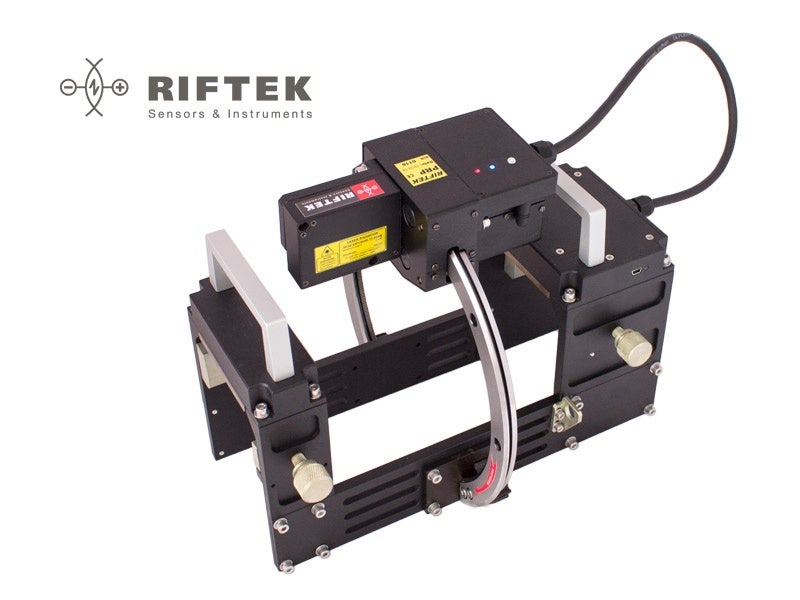

The laser wheel profilometer is employed for measuring geometrical parameters of the wheel flange (thickness, slope and height) and tire thickness, taking a full profile of the wheel roll surface.

The Triangulation Laser Module placed inside the profilometer casing performs linear scanning of the wheel surface. Measurement results (geometric parameters and profile of the surface) are displayed on the PDA, can be saved in the PDA memory, and transferred to the PC database.

The device is supplied with a database and software package for wheel set wear data storage and processing.

An operator mounts the laser scanning module onto the wheel to be measured. Having received a command from PDA or PC, the laser module performs a non-contact scanning of the wheel surface.

The electronic gauge is designed for measuring back-to-back distances of railway, metro, and tram wheels during wheel set checkups, examinations, repairs and formation. Measurements are made directly on the rolling stock, without wheel set roll-out.

A PDA based handheld instrument is employed for laser scanning and measuring brake disks wear parameters. An operator mounts the laser scanning module onto the disk to be measured. Having received a command from PDA or PC, the laser module performs a non-contact scan of the disk surface.

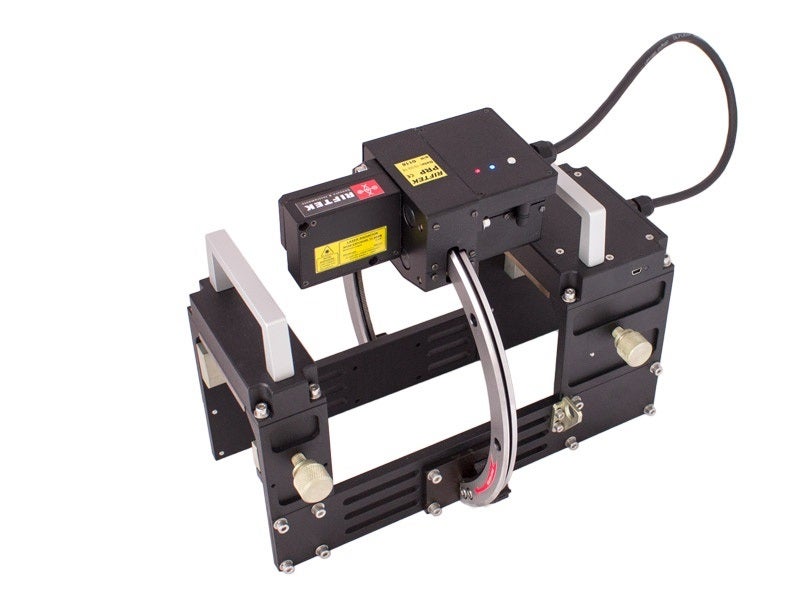

The portable laser rail profilometer (PRP) is designed for the non-contact registration of cross-sections of the railhead acting face.

The main functions of the PRP are:

The system is intended for the contactless control of displacement dynamics of power rails.

The operation principle is based on the control of power rail position using triangulation sensors placed under the rail.

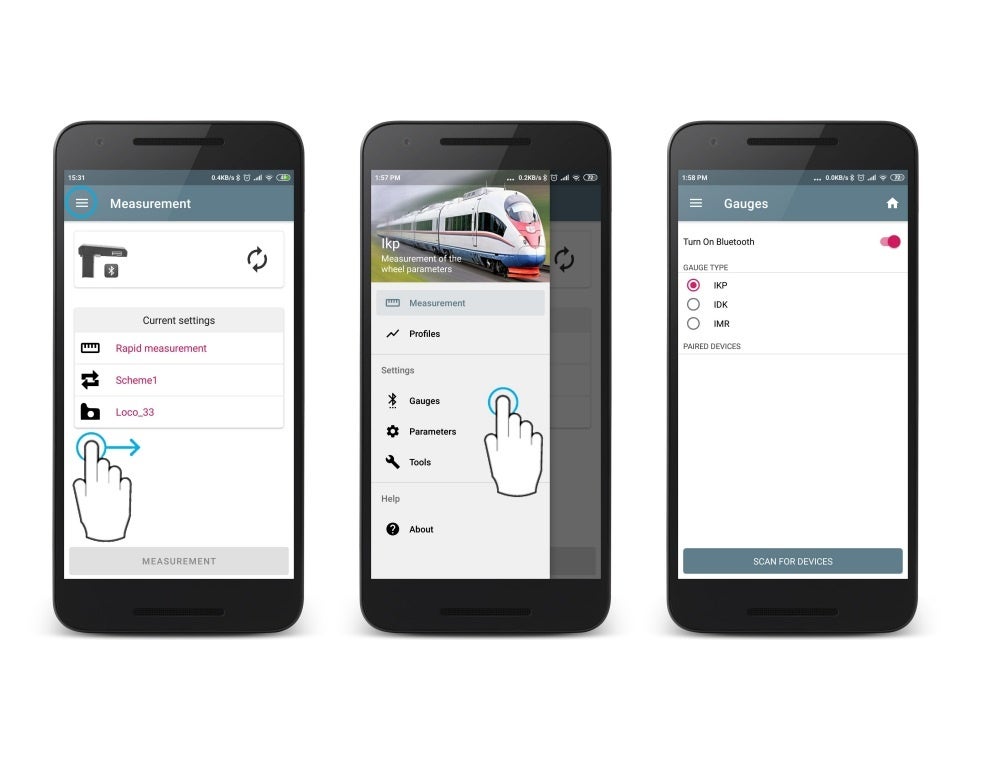

RIFTEK’s Android App is designed to work with hand-held devices for wheelsets parameter measurement. By installing the program on a phone or tablet, users can work with IKP-5, IDK, and IMR, without PDA or with both PDA and the phone.

Some of the software’s new features include:

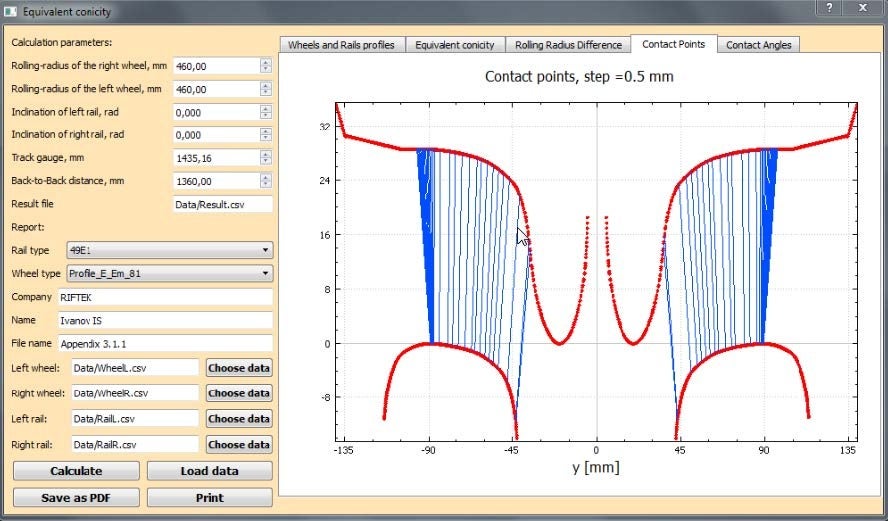

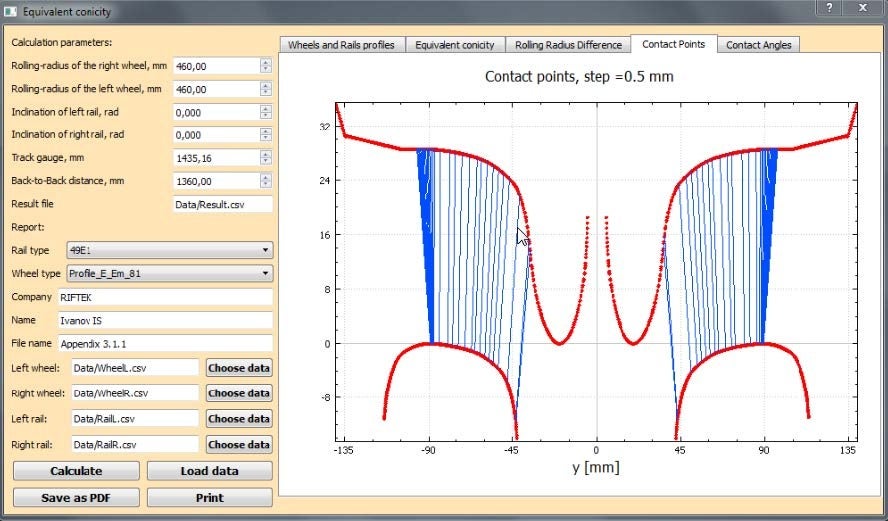

Equivalent conicity is a parameter that is used when investigating the dynamic interaction between railway vehicles and tracks. The parameter describes the behaviour of the contact between wheels and rails for straight and large radius parts of the track.

The program calculates the following parameters:

The program can use data from the Railway wheel profile gauge IKP-5, the Rail profile measurement gauge PRP, or other any sources. The only requirement is the description of the real wheels and rail profiles presented in tabular form.

The Android App is designed for working with hand-held devices for wheelsets parameter measurement.

IMR Series back-to-back distance measuring gauges.

IMR-L Series back-to-back distance measuring gauges.

The maximum output power is 4.8 mW and the gauge belongs to the 3R laser safety class.

RIFTEK products are delivered in more than 70 countries.

Brake disk parameters are calculated automatically after laser scanning.

Equivalent conicity is a parameter that is used when investigating the dynamic interaction between railway vehicles and tracks.

The main functions of the PRP include obtaining information on the cross-section profile of the working railhead surface.

The device is supplied with a database and software package for wheel set wear data storage and processing.

The system can be easily installed at any type of rail infrastructure.

The gauge contains a numeric display to show the value of the wheel diameter.

The gauge contains a numeric display to show the value of the wheel diameter, and the IDK-BT gauge contains a Bluetooth interface to transfer results into the wheel-set wear database management system.

Based on the experience gained in operating the first 3DWheel systems in St Petersburg and Ankara, Riftek has developed and started production of the next generation 3DWheel.60 systems.

While developing the new generation of popular gauge, we have tried to resolve encountered problems to enhance the device reliability and accuracy, taking into account all the wishes and recommendations of our customers and partners we got during exploitation of IKP-5.

Systematic and effective control of diameter and profile of wheelsets, back-to-back distance is an important component of monitoring of wheel wear arising in the process of wheelset operation

The system can be easily installed at any type of rail infrastructure.

The measurement method is based on the diameter calculation using the known length of the segment chord (the distance between the ball bearings centres), which is obtained when placing the gauge onto the wheel.

An operator mounts the laser scanning module onto the wheel to be measured. Having received a command from the PDA or PC, the laser module performs a non-contact scanning of the wheel surface.

Measurements are made directly on the rolling stock without wheel set roll-out.

The devices are supplied with database and software packages for disk wear data storage and processing.

An operator mounts the laser scanning module onto the railhead to be measured.

The Android App is designed to work with hand-held devices for wheelset parameters measurement.

The program can use data from the railway wheel profile gauge IKP-5 and rail profile measurement gauge PRP.

The system can be easily installed at any type of rail infrastructure.