Static Train Weighing Systems

Accurate static weighing is vital for maintenance depots and manufacturing facilities. At Weighwell, our Static Train Weighing Systems deliver precise individual wheel weight measurements, giving engineers the insight they need to identify and correct imbalances. By detecting uneven loads early, depots can address issues before they lead to safety risks, component wear or operational delays.

Static weighing is also essential for ensuring newly built or refurbished vehicles meet the required safety standards before entering service. This makes it a key tool passenger rolling stock manufacturers who demand dependable performance from their fleets.

Our systems are portable, quick to install and flexible enough to handle a wide range of rolling stock, from trams and passenger railcars to locomotives and high-speed trains.

Configurable solutions to match your needs

Weighwell offers static weighing systems in a range of configurations to suit different operational requirements:

- Axle Weighing – Using a single Portable Train Weigher (PTW) unit, each axle is weighed individually, providing precise wheel load data and highlighting any imbalance across the axle.

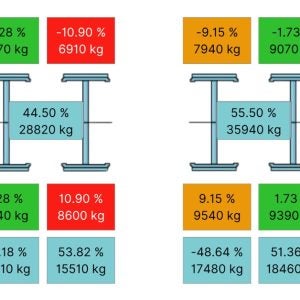

- Bogie Weighing – Portable bogie weighing systems (two-axle or three-axle) measure the entire bogie in one operation. This helps highlight weight differences between bogies and prevent suspension or wheelset wear that could impact ride quality, if left unchecked.

- Railcar Weighing – Using multiple PTW units positioned under each axle, the entire railcar or locomotive can be weighed at once. This provides precise, real-time measurements for every wheel, axle, and bogie, while minimising the influence of track gradients on results.

- Multi-Railcar Weighing – By deploying PTW units under every axle of the train, multiple railcars can be weighed simultaneously. This approach reduces vehicle movements, saves time and ensures consistent results across the entire trainset, ideal during vehicle production or approval testing.

Benefits of portable static train weighing systems

- Up to 0.1% Accuracy – Achievable with a PTW unit under each axle.

- Quick to Install – At only 500mm in length, PTW units fit between rail fastenings and require no permanent track alterations

- Flexible Operation – Compatible with different track gauges, rail profiles and types of railway track (including ballast, pitted and pillar-mounted).

- Real-Time Data – Instant weighing results via an indicator or software (laptop) interface.

Key applications

- Passenger and freight maintenance depot

- Railcar manufacturing facility

- Overhaul and refurbishment workshop

- Commissioning and acceptance testing

Why choose Weighwell?

Since launching our patented Portable Train Weigher in 1997, Weighwell has provided rail operators worldwide with innovative, portable weighing solutions that combine accuracy with operational flexibility. Our static weighing systems are trusted by major manufacturers and operators to improve safety, efficiency and reliability.