Welding Alloys

Alloyed Cored Wires, Automated Welding Equipment and Joining Applications

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Since its foundation in 1966, the Welding Alloys Group has become the global specialist in the development of low and high alloyed cored wires, automated welding equipment for surfacing and joining applications.

Automated gauge corner welding machine

For repairing the tramway rails we developed our automated gauge corner welding machine, GCR D3 Touch, and cored wire for restoration of worn grooved rails in situ. This offers a cost-effective approach to extend rail lifetime and up to 80% cost saving compared to replacing worn track. Welding Alloys GCR D3 Touch, with D3 Touch control technology, allows fully automated control of the welding process with easy operator intervention.

Specifications of the GCR D3 Touch welding machine:

- Lightweight welded aluminium frame

- Self adjusting to gauge’s size

- Digital D3 Touch pendant controls

- Tactile follower

- Polymer coated wheels

- Compact flux recovery system

- Downloadable data logger

- Temperature monitoring system

- Weld up or down 1:10 gradients and 12m radius curves

- Halogen flood light for illuminating welding area

- Manually operable clutch

Specially designed cored wires for railway / railroad systems

Crossings respiratory frogs are subjected to daily metal-to-metal wear, abrasion and impact, and consequently they become worn. Refurbishment by weld rebuilding allows you to quickly restore and repair the crossing in-situ, recycle used crossings in the workshop, reduce maintenance downtime and rail / track closures and achieve cost savings of 80% compared with replacement costs.

Specially designed cored wires for hard facing tamping tines

Tamping is an essential part of track maintenance used to pack the ballast under sleepers. In general, tines are rejected after 15%-20% wear in their thickness / width. A long service life of the tines weld hard faced with WA products ensures a consistent quality of tamping and reduced costs.

Repair and maintenance of railroads

In 2011 Welding Alloys acquired the company Track-Weld, which has experience in repair and maintenance of railroads all over the world. These projects include:

Canada

- Canadian National Railway (CN)

- Canadian Pacific Railway ext

Mexico

- FerroMex

- Kansas City Southern de Mexico

USA

- Burlington Northern Santa Fe (BNSF)

- Union Pacific Railroad (UP)

- Norfolk Southern

- CSX Transportation

- Kansas City Southern Railway

Welding Alloys is currently working with:

France

- SNCF unique approval

Germany

- Berliner Verkehrsbetriebe, DB approval

United Kingdom

- TATA Corus-Cogifer TATA approval

White Papers

Projects

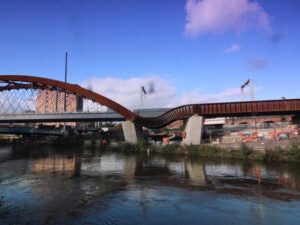

Wales Upgrade Project

The Wales Upgrade project involves a series of targeted upgrades to the railway network across South Wales.

Great North Rail Project

Great North Rail Project (GNRP) involves a series of upgrades to the railway network across the north of England.

Press Releases

Contact Details

Website

Email Address

Address

,

Fowlmere,

nr. Royston,

SG8 7QS,

Hertfordshire,

United Kingdom