+S Battery Machines: Enhancing Thermit® Welding, Not Disrupting It

The +S battery-powered machine portfolio is built with one goal in mind: to make things better for the welding teams.

Goldschmidt is a family-owned group of companies that provide rail infrastructure solutions, including rail joining and construction products, as well as track maintenance and infrastructure solutions.

You have successfully submitted your enquiry. Someone from our company will respond ASAP

Goldschmidt is a family-owned group of companies operating worldwide in the field of rail infrastructure. Since 1895, the company has been shaping the rail-bound mobility of tomorrow, along with its customers and partners, with products and services for the joining of rails, modern construction of railway tracks, and the inspection and maintenance of track infrastructure.

By working closely with its customers on new developments, Goldschmidt gains important insights to refine and optimise its products to deliver effective and reliable solutions. Thanks to its worldwide production, services, and sales locations, Goldschmidt’s products and services are available locally. Customers are also able to access support from local contacts.

Whether optimising welding and inspection processes or implementing a custom-tailored solution, customers can rely on Goldschmidt’s expertise to guide customers throughout the entire project. The company’s solutions can be customised according to individual requirements and needs.

All over the world, rails are welded using Goldschmidt expertise. Goldschmidt offers a number of solutions for the repair and maintenance of rails and switches to extend the rails’ service life and ensure that all types of trains and trams run quietly and safely while also being environmentally friendly.

Original Thermit® enables the excellent joining of almost any type and grade of rail. State-of-the-art production, continuous development, and strict quality controls guarantee the reliability and durability of the Thermit® rail joining process. Goldschmidt develops, produces, and supplies all of the associated equipment, machines, and materials.

The professional grinding and maintenance of rails and switches extends the service life of the rails, reduces lifecycle costs, and reliably reduces noise emissions from train operations.

Goldschmidt’s insulated rail joints offer maximum safety, reliability, and durability under a wide range of operating conditions. They meet the local requirements of all global railways and can therefore be used safely and reliably anywhere.

Goldschmidt develops and manufactures equipment and machines for worldwide use in track construction and maintenance, as well as specialised tools for Original Thermit® welding processes. The company’s product portfolio features advanced and sustainable drive variants and power units that deliver efficiency, precision, and ease of use. Products such as magnetic track barriers and buffer stops significantly increase safety on the track and in stations.

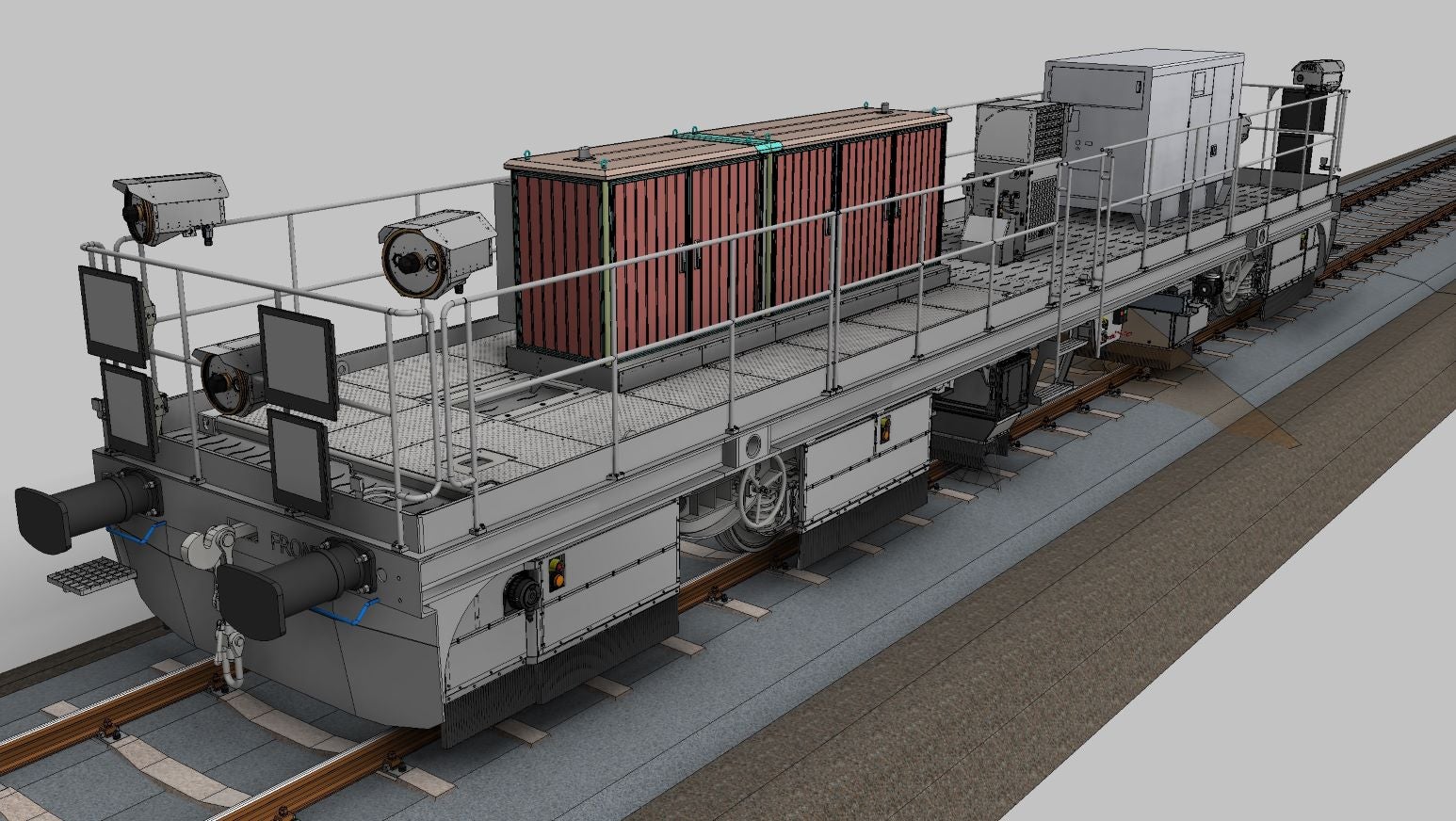

Goldschmidt’s cutting-edge technologies for the identification and evaluation of rail defects, track geometry, rail profiles, and wheel profiles provide precise measurement and testing results in a standard format. Whether as a hand-held inspection device, integrated into trolleys, carts, road-rail vehicles, or inspection trains, Goldschmidt makes rail tracks safer.

Goldschmidt’s wide range of high-end road-rail vehicles cover a variety of maintenance, construction, and inspection tasks in the track area. Its products include overhead line vehicles, tunnel and bridge inspection vehicles, crane vehicles, welding vehicles, and other customised solutions for efficient and reliable work on railway infrastructure.

With the company’s digital Dari solutions, rail infrastructure operators can easily record and analyse their track-related data digitally and access it at any time. This enables users to operate rail networks safely, flexibly, and efficiently. It also helps to future proof rail infrastructure.

The +S battery machine portfolio from Goldschmidt provides the company’s guaranteed levels of quality and is now even more sustainable thanks to the use of new technologies, optimised work processes and operations, and improved occupational safety.

+S evolves the use of Goldschmidt machines. The long-lasting and powerful batteries from the company’s partner, EGO, can be flexibly exchanged between the machines in its battery family. Customers can experience the future of sustainable and efficient energy use with Goldschmidt and benefit from new technology and increased productivity.

The +S battery-powered machine portfolio is built with one goal in mind: to make things better for the welding teams.

Under the framework contract, GRAW will deliver inspection vehicles equipped with cutting-edge sensor and camera technology.

As part of the first construction phase, scheduled for completion by the end of 2026, the company Rickardsson Bygg AB has been commissioned to construct a new vehicle assembly hall.

Rail Live is the world’s leading railway conference and exhibition, bringing together a range of rail operators, researchers, and suppliers.

Goldschmidt has secured a contract to supply a rail inspection vehicle with combined testing, measuring and analysis technology for the Berlin underground.

In the financial year of 2018, Goldschmidt Thermit Group increased its global sales revenue by 17% to reach €185m.

Goldschmidt Thermit Group has expanded its product range in the area of measurement technology for the railway sector, continuing its global growth strategy.