A commercial and political powerhouse, America’s Northeast Corridor (NEC) is one of the most densely populated areas of the country. The NEC stretches from Washington DC at the southern end, through Baltimore, Philadelphia, New York City along the southern New England coast to Boston.

On this busiest of US rail routes with several train operators, the most heavily used section is between Pennsylvania and New York City.

At the project outset with approximately 45% of the market in traffic in the NEC, Amtrak had a strong presence but sought to consolidate its position established by the 125mph Metroliner service created in the late 1960s by Penn Central Transportation.

In the face of growing competition from road transport along the improved Interstate 95 freeway, and airline shuttle services, Amtrak looked to the high-speed rail technologies used by European operators.

The project

Amtrak decided the transport competition should be met through rebranding its NEC services and the introduction of a new fleet of trains. When conceived in 1995, the project was known as the American Flyer, but Acela (derived from ‘excellence’ and ‘acceleration’) was eventually applied. The new brand was to reflect the main benefits which Amtrak aimed to offer.

A consortium led by Canadian firm Bombardier who had North American rights for Alstom’s TGV technology won with its design against competition from Siemens, which demonstrated a version of its German ICE and ABB, which shipped in a Swedish version of the X2000.

Amtrak, eager to build ridership on its premier route, slashed fares by 22% on its Acela Express service between Boston and New York from August 2002. Initially the Acela name was deployed as a catch-all for Amtrak’s NEC services, but customer confusion and the need to sustain brand identity later led to ‘Acela Express’ becoming from 2003 the only application of the name and specific to high-speed services by the new trains.

Of the 456-mile NEC from Washington to Boston, Amtrak operates Acela Express trains on 363 miles.

Amtrak started work on track maintenance projects in April 2009 to improve the Acela Express service between Washington, New York and Boston. The improvement works were completed in phases during the first quarter of 2010.

Infrastructure

The Acela project involved a series of improvements to existing stations, including major railheads in New York, Wilmington and Baltimore, with a new station, Route 128, built outside Boston. A major problem was keeping the Acela project on schedule.

The NEC is a notoriously twisting route, a major influence in opting for tilting trains to allow accelerated services with the least passenger discomfort. A patchwork of infrastructure with several owners rather than a cohesive whole, the route also features different electricity supply systems. Engineers faced a number of barriers in their work in preparing for Acela operations, notably north from New York City.

Balfour Beatty Construction and its joint venture partner, Mass Electric Construction, adopted a novel method to help the system overcome the problems inherent in energising the moving sections of the bridges.

Rolling stock

Amtrak announced a consortium led by Bombardier as contract winners in 1996 in a deal that included supplying other electric locomotives and building three depots. A significant risk taker in the project that included a requirement for largely US manufacture and a maintenance agreement, Bombardier’s payments were to be from the anticipated higher receipts that Amtrak would gain with the new service.

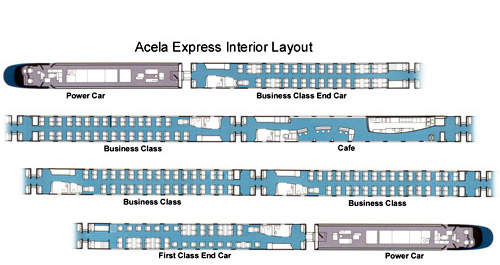

Unlike usual North American practice, the trains are not equipped with steps and thereby can only use platforms built for their use. The train configuration is a non-tilting electric power car at each end and six tilting intermediate trailers.

Alstom provided traction equipment and bogie design, while Bombardier, drawing upon experience with the Canadian LRC trains, manufactured body shells and carried out assembly at its plants at La Pocatiere (Quebec), Plattsburgh (New York), and Barre (Vermont). Concern over clearances on some parts of the route meant that the full 6.5° tilt capability could not be used throughout.

Entry into service was delayed for a year by wheelset problems. In mid-2002, most of the fleet had to be halted for urgent shock absorber examination and 2005 saw brake-disc faults causing service disruptions.

In spite of the problems, Acela Express represents a significant improvement in US rail passenger standards and a highly competitive product against a domestic airline industry that was far from immune to business and operational difficulties in the new century’s first decade. The fastest Acela Express timing for the 456 mile (734km) Washington, DC to Boston’s South is just over 6 1/2 hours, an average of 72mph (116km/h). The 225 mile (362km) New York Penn Station to Washington, DC takes 2 hours 48 minutes, an average of 80mph (129km/h).

However, in 2007 the Republican Committee on Transportation and Infrastructure, stated that the speed of Acela Express was much lower than that of other express trains globally. The average speed of Japan’s high-speed train Shinkansen is 125mph and France’s TGV trains average 173mph, while Germany’s high-speed trains run at 153mph.

The committee also commented that Acela has had many mechanical problems in the past and falls short on reliability.

Signalling and communications

Trainsets are equipped with a two-frequency, nine aspect cab signalling system, which receives information transmitted through the rails in the form of electrical signals, and is displayed in the cab.

The driver is supervised by an Automatic Train Control (ATC) system, with the trains governed by Amtrak’s own ACSES (Amtrak Civil Speed Enforcement System) equipment which automatically adjusts a train’s speed within line-side speed restrictions and signals on-the-move power supply changes.

In July 2006, Amtrak installed wireless electronic credit card processing terminals in all of its Acela Express cafe cars to enable credit card transactions for the purchase of food and beverages.

The future

Sustaining the project’s success, 2.6 million passenger journeys were made on Acela Express in 2006, an 8.8% increase over 2005. The second generation of Metroliner coaches were relegated to secondary services from 2006.

The number of passenger journeys on the Acela Express increased by 6.5% to 3.3 million in 2008 over 3.1 million passengers in 2007, which brought in $468m in revenues to Amtrak.

Amtrak started work on track maintenance projects in April 2009 to improve the Acela Express service in the north-east regions between Washington, New York and Boston. The improvement works were expected to be complete by September 2009.

Track condition and route congestion remain the main limiting factors for further acceleration through sustained running or using Acela Express’ design capability. Although Amtrak has expanded overall NEC workings, a wider application of high-speed rail has yet to happen in the US.