Image House PantoInspect

Automatic Pantograph Monitoring System

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

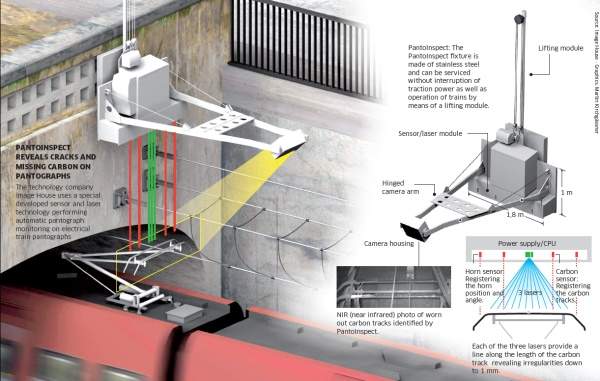

The PantoInspect pantograph monitoring system automatically inspects carbon strips and malfunctions on electrical train pantographs in motion, making torn-down overhead wiring a thing of the past.

Continuous monitoring systems for measurement of pantograph condition

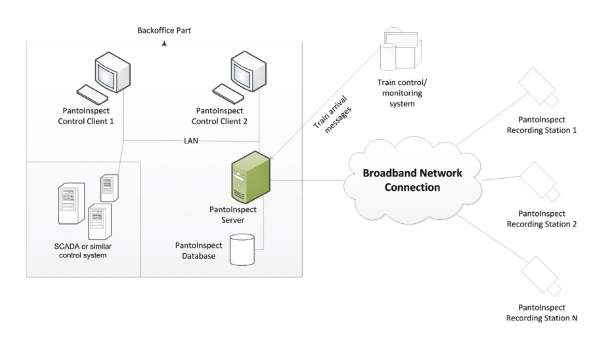

The PantoInspect pantograph monitoring system conducts real-time continuous measurements of the condition of pantographs as trains pass by. At train speeds of up to 180km/hr, pantograph defects are detected and reported to rail companies via the PantoInspect data processing system. Train operators are then made aware of any problems, giving them an opportunity to take relevant action and prevent torn-down overhead wiring.

Maintenance scheme defect detection for damage and cost avoidance

Tearing down wire is not only inconvenient but both very costly and dangerous to passengers and personnel. By detecting serious conditions of pantographs before it is too late, considerable damage and cost can be avoided. Detecting smaller defects may also allow for a more effective maintenance scheme.

PantoInspect works on operational trains so there is no need to move vehicles to service garages for inspection. The PantoInspect solution is an obvious choice for railway companies wanting to proactively manage and reduce the number of delays and accidents.

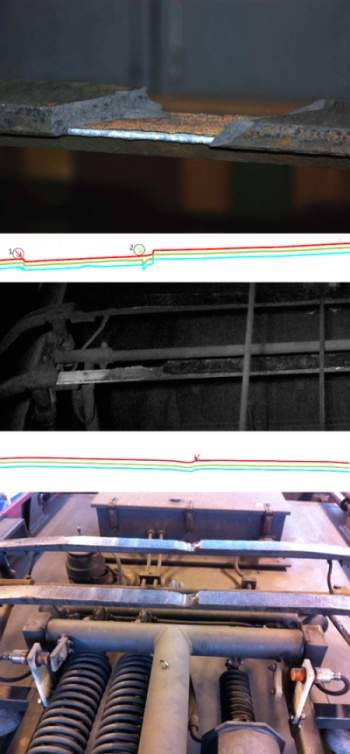

Cracks and carbon strip tearing detection

The PantoInspect system is unique because, along with detecting cracks and tearing on carbon strips, it also allows for continuous inspection of horns, uplift pressure and train speed, as well as working bidirectional and independent of the direction of the trains.

Sensors and lasers provide digital images

PantoInspect uses advanced sensors and laser equipment to provide detailed digital images during train passages. Lasers light up the carbon strip on the train pantograph, revealing cracks and other damage that ultimately may tear down overhead wires. Pictures of identified problems are then transferred to a main computer system for further analysis and relevant action by the network surveillance personnel.

About the PantoInspect pantograph monitoring system

The PantoInspect pantograph monitoring system operates around the clock for railway company Rail Net Denmark. At the turn of 2011/12, this unique solution was fully implemented, aiming to increase reliability by ending the battle against demolished and torn-down overhead wiring on the Copenhagen S-train network.

Divisional director at Rail Net Denmark Vilhelm Mortensen explains: “The system will reduce the number of delayed trains, benefiting the passengers, lower maintenance costs, benefiting Rail Net Denmark, and reducing security risks, benefiting everyone.”

Company profile

Image House, an experienced Danish technology company, produces and markets solutions for increased security and performance within the railway sector.

Please do not hesitate to contact us if you require more information about the PantoInspect pantograph monitoring system. A demonstration may also be arranged upon request.

White Papers

Contact Details

Website

Email Address

Address

Copenhagen,

1577,

Copenhagen,

Denmark