On-going investment by passenger information specialist Infotec into in-house manufacturing capabilities has seen the installation of a Fully Anechoic Chamber (FAC), allowing the market-leading company to test its own equipment to internationally accepted noise criteria.

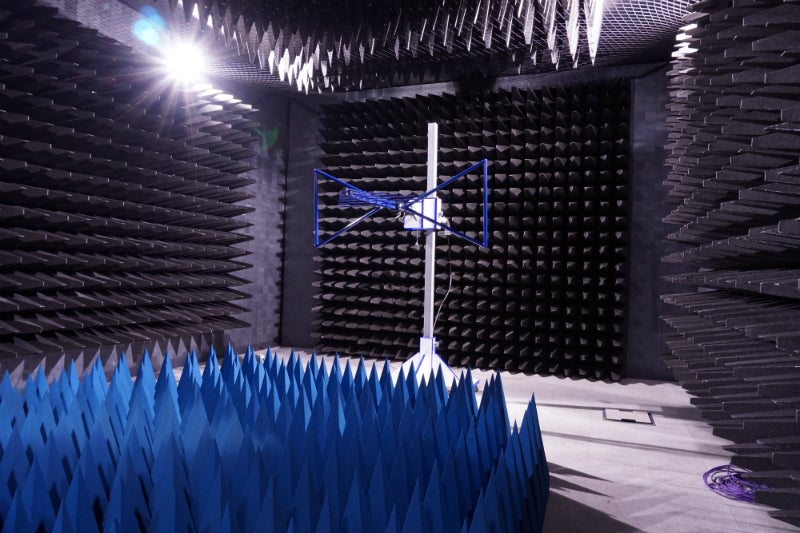

An FAC is a metallic enclosure lined with ferrite tiles and external radio frequency (RF) absorbers. It is designed to test for both emitted electromagnetic interference or ‘noise’ and the ability of equipment to ignore such interference from an external source.

The lining, along with the metallic ‘box’, offers protection from RF noise and prevents Infotec’s susceptibility test equipment from affecting local neighbours.

This can therefore be used to both listen to the noise that Infotec equipment generates without any external interference from sources such as TV, mobile phone and radio and also prevents transmission of unwanted noise during susceptibility testing.

The science behind the tests is complex, as is the calibration of the chamber to ensure it meets the set standards. What is important is the fact that the chamber is designed to simulate ‘free space’ which has an impedance of 377 Ohms.

The word chamber may conjure up images of a small space, but the one installed at Infotec’s headquarters in Ashby-de-la-Zouch, Leicestershire is 8m x 4.5m x 3.5m high.

Having the chamber allows Infotec to test sub-assemblies prior to them being incorporated into final equipment, allows samples from production batches to be checked for compliance and is ideal for type testing of new designs.

Commenting on the installation, Infotec Managing Director Tim Court says: "This large scale investment underlines our commitment to ensuring the quality of our products and services is of the highest calibre from start to finish.

"Bringing the testing in-house also enables us to make processes as efficient as possible, helping reduce lead times."