Fraunhofer IPM

Railway Measurement Systems for High-Speed Inspection Trains

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Monitoring the condition of railway infrastructure is an essential precondition for the safe and reliable operation of railway lines. Particularly cost-effective is the regular use of inspection trains equipped with measurement systems.

Such systems need to measure accurately and quickly through high-speed inspection trains, thus minimising adverse effects on regular traffic. The devices should be robust, reliable and low-maintenance. In response to these requirements Fraunhofer IPM offers a series of modular railway measurement systems for high-speed inspection trains, which are optimised for varying tasks.

Contact-wire ranging system (CRS)

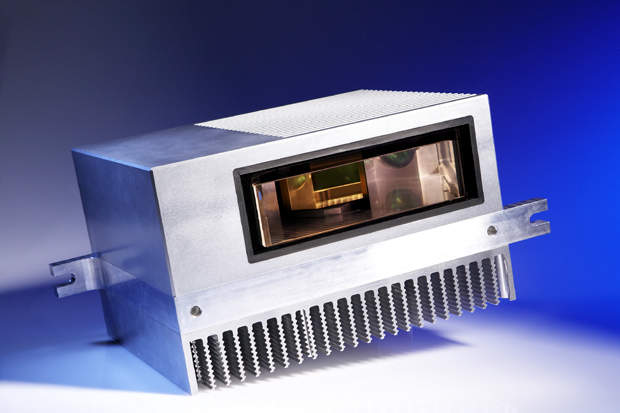

The CRS determines the position of up to four contact wires simultaneously without touching them, at speeds of up to 350km/hr. The core of the CRS is the new sector profile scanner (SPS), which is based on distance measurement with a high-frequency modulated laser beam and the phase-measurement technique.

The acquisition range of ±35° is continuously scanned by a mirror with a maximum frequency of 800Hz. Height and stagger of the wire are deduced from the scan angle and the distance.

With a set of linear transducers, which record the rotary movement (roll) of the bogie, the wire positions can be referenced to the track.

Contact wire wear-monitoring system

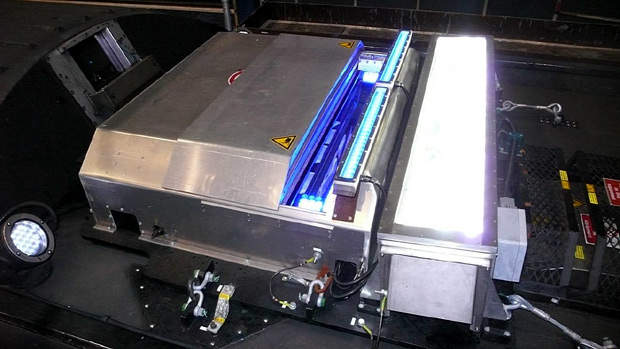

The contact wire wear-monitoring system (WWS) deduces the degree of wear from the width of the sliding surface at contact wires with a round bottom.

A special unit illuminates the wires from below. Information about the wire position (e.g. from the CRS) is used to focus two cameras, which capture the images of the sliding surface. A maximum of four wires can be processed in real-time and without gaps, at speeds up to about 200km/hr.

3D clearance-profile scanner (CPS) for railways

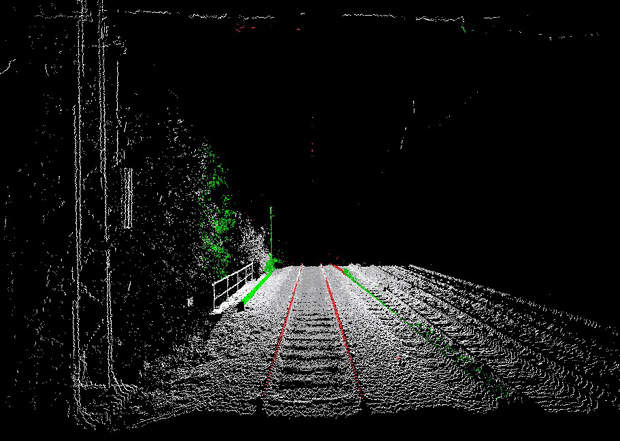

The CPS continuously scans the surrounding of the track with up to 200 profiles per second. Due to the continuous movement of the wagon, a three-dimensional image of the environment is generated. With each rotation the rails are also detected, which allows users to refer the values to the track centre, without any additional sensors.

The full functional versatility of the CPS sensor is achieved by several optional software modules, which perform an online analysis of the data and yield results of typical measurement tasks: height and stagger of the contact wire, distance to adjacent track, and ballast profile.

With these software modules the CPS becomes a unique multi-purpose sensor.

High-speed clearance-profile scanner for railways

The high-speed profiler (HSP) is a speed-optimised version of the CPS. Two HSP heads work on the LIMEZ III, the new clearance-profile measuring train of Deutsche Bahn.

The novel HSP scanner uses two laser beams, yielding twice the profile rate of conventional scanners. Together with an increased rotational speed one HSP sensor measures more than 550 profiles each second with a total of 2 million data points every second.

Sophisticated software performs online filtering, data reduction, consolidation and infringement analysis.

Optional software modules can extend the versatility of the HSP, for example to give the distance to the adjacent track.

Features of high-speed railway measurement systems

Fraunhofer IPM’s high-speed railway measurement systems are non-contact, provide excellent resolution even at high vehicle speeds, ensure accurate results and data processing in real time (for data reduction and analysis), have built-in calibration, and possess active systems and robust, hermetic housings. Climatised and semi-automatic cleaning versions are available.

Benefits of high-speed railway measurement systems

Our high-speed railway measurement systems provide a wide range of benefits, including:

- No hindering of regular traffic by slow inspection trains

- Manageable data quantities

- Real-time availability of data and reports, and minimised post-processing

- Stable performance over long periods

- Operation day and night and under extreme temperatures

- Low maintenance and reliable operation

- All systems are tailored to the requirements of each specific railway organisation

- Modular combinations: extendable for additional tasks or higher performance in future

White Papers

Press Releases

Contact Details

Website

Email Address

Address

D-79110 Freiburg,

Germany