P-TEC

Sleeper Technology and Factory Planning, Track Systems for Concrete Sleepers, Slab Tracks, Turnout Sleepers and Standard Rail Sleepers

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Having evolved from the former DYWIDAG SLEEPER GROUP, P-TEC’s expertise lies in the development of pre-stressed concrete sleepers for light track, high-speed track, heavy-haul track and ballastless track systems, the latter being well known under the name RHEDA. The product range P-TEC provides comprises both hardware and software services including:

- Sleeper statics analysis

- Individual sleeper design

- All required engineering for planning sleeper production (plant-layout, logistic, quality management)

- Supply of machinery and equipment

- Installation and setting into operation of production

- Production accompanying consultancy

STANDARD RAIL SLEEPERS, TURNOUT SLEEPERS, SLAB TRACK, MONOBLOCK SLEEPERS AND SPECIAL SLEEPERS

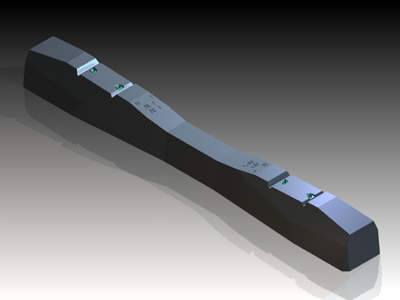

P-TEC supplies the design and calculations for all types of pre-stressed concrete sleepers including normal track sleepers, light rail sleepers, heavy-haul sleepers, monoblock sleepers, slab track sleepers, turnout sleepers and craneway sleepers. Calculations are based on international standards such as EN or AREMA. Modern statics programs permit the design of unconventional sleepers that are not covered by any norms or references, e.g. three-rail sleepers for simultaneous use with broad gauge (1,668mm) and European gauge (1,435mm).

The sleeper’s statics analysis and the resulting design draft are decisive prerequisites when planning a suitable manufacturing plant. However, sleepers can be designed according to defined specifications and loads for production in an existing plant.

Country-specific regulations and standards and international guidelines are taken into account when calculating and designing new sleepers. Design phase sleepers of the first trial production are tested according to the appropriate regulations (usually EN or AREMA).

SPECIFIC PLANT CONCEPT: DIRECT/ INSTANT DEMOULDING AND LATE DEMOULDING

With one of our manufacturing options – direct / instant demoulding or late demoulding, P-TEC will find the most suitable and economical plant concept for your specific site conditions.

DIRECT / INSTANT DEMOULDING: PRETENSIONED / POSTTENSIONED

This method is characterised by the direct demoulding of the sleepers straight after compaction. Only a limited number of sleeper moulds is required for this process. With its two systems, DSA and DSR, P-TEC provides a posttensioned method with positive anchorage (DSA) as well as a prestressed method with direct bonding (DSR). Both are perfected manufacturing methods used in installations worldwide.

Thanks to the limited number of moulds required, the DSA and DSR processes offer the greatest flexibility. It is possible to work with interim storage, exceeding the curing period to reach the required compression strength without additional moulds. It allows manufacturers to adjust the curing time to the quality of locally available aggregates.

LATE DE-MOULDING: PRETENSIONED

Carousel production and long-line production offer economic mass production for a single type of sleeper. Late demoulding processes depend on high-quality aggregates to achieve reasonable curing periods. Curing times in excess of 16 hours require additional moulds without increasing output capacity. If only a single type of sleeper is produced and high-quality aggregates with curing times below 16 hours are available then late demoulding processes permit the implementation of highly efficient solutions.

FACTORY PLANNING

Plant concepts are successfully implemented by P-TEC using a systematic approach and professional project management.

In accordance with economic and technical aspects, the first step is to produce detailed project specifications and define the corresponding manufacturing concept. Starting with a manageable investment, the plant’s capacity can be increased in steps by means of additional automation stages.

The individual plant sections are precisely tuned to each other, from the mixing unit through to quality assurance and storage logistics for the final product. We install your plant equipment on site, and assist your employees with a comprehensive training programme.

P-TEC takes complete responsibility for the production line, thus laying the foundation for planned success.

Contact Details

Website

Email Address

Address

D-82515,

Wolfratshausen,

Other,

Germany