TÜV AUSTRIA TVFA

Railway Component Testing and Certification Services

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

TÜV AUSTRIA (TVFA) offers independent testing, inspection and certification services as an accredited body to the rail industry (EN ISO/IEC 17020, 17025, 17065).

We test, approve and certify fixed equipment such as rail fastening systems, clips, sleepers, contact wire systems and rolling stock components.

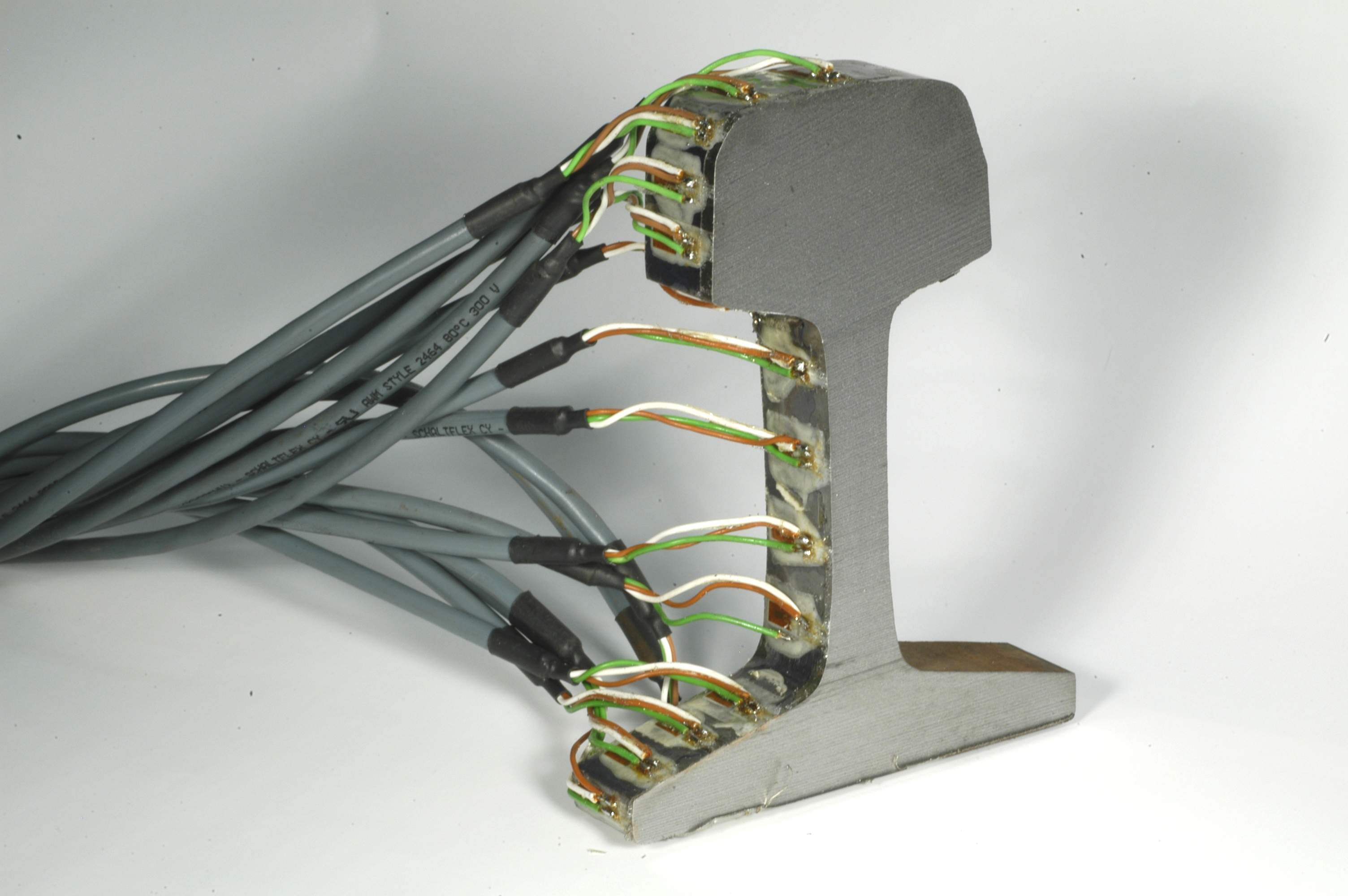

TVFA also performs mechanical testing and characterisation of components and materials. We test under realistic conditions and have appropriate facilities, even for complex structures and large components. Our range of state-of-the-art metallographic methods completes our mechanical testing services.

Our experts assist during design, test planning and approval procedures, as well as implement customer-specific requirements. Our fully equipped workshop can prepare any specimen or experimental setup, including measurement needs.

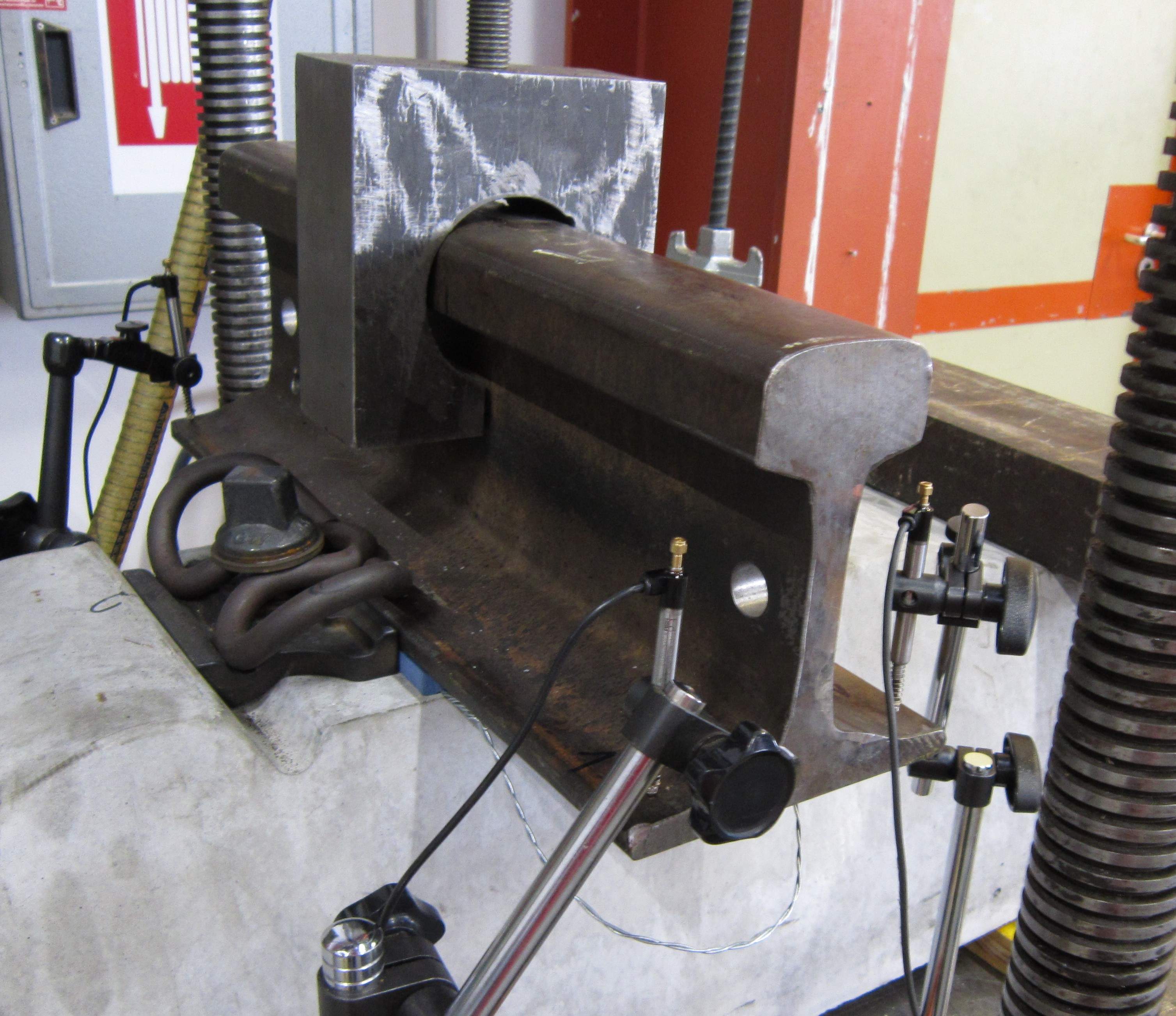

Railway fixed equipment testing and approval services

TVFA performs full approval testing for flash-butt or aluminothermic welding processes (EN 14587, EN 14730), rail fastening systems (EN 13481, EN 13146), sleepers (EN 13230, EN 16431).

We also test any component or system, including insulated rail joints and clamping elements in accordance with technical delivery conditions.

Many customers ask for special tests during their R&D process, such as testing under special environmental conditions (from -70°C to high temperatures), unusual loads or measurement conditions and fatigue testing over long durations and corrosion tests in our salt spray chamber.

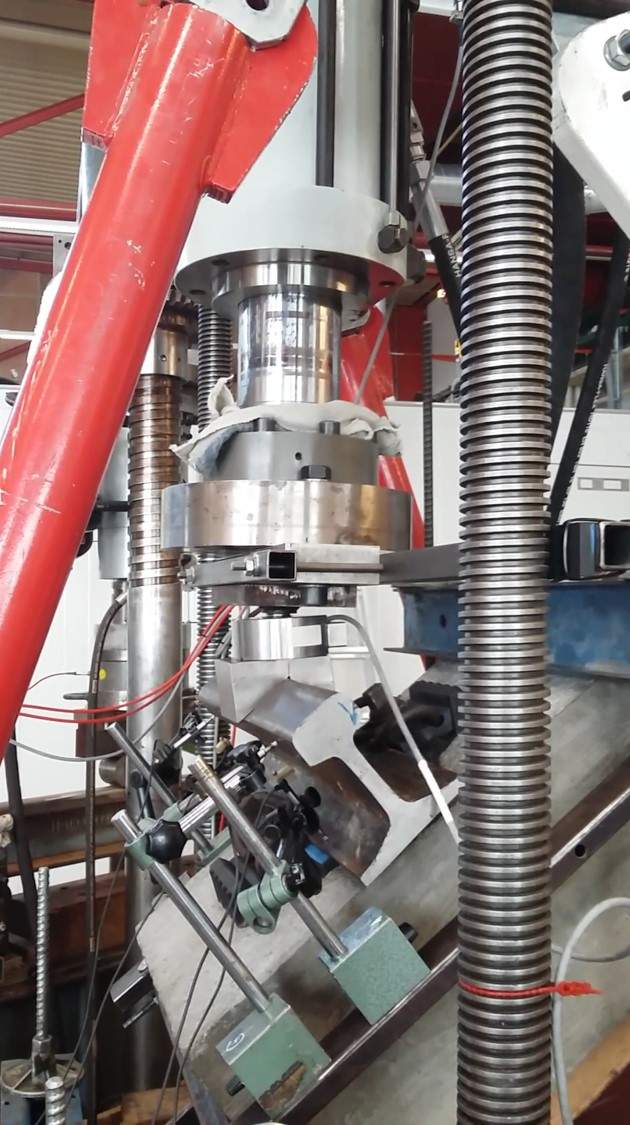

Mechanical testing laboratory and workshop

TVFA operates a state-of-the art mechanical testing laboratory with a broad range of testing machines, including a number of low-cycle and high-cycle fatigue testing facilities up to a 60tkN load and specimen cross sections of 2m by 3m.

Our tensile testing capabilities range up to 2.5MN, while specimen lengths reach 15m.

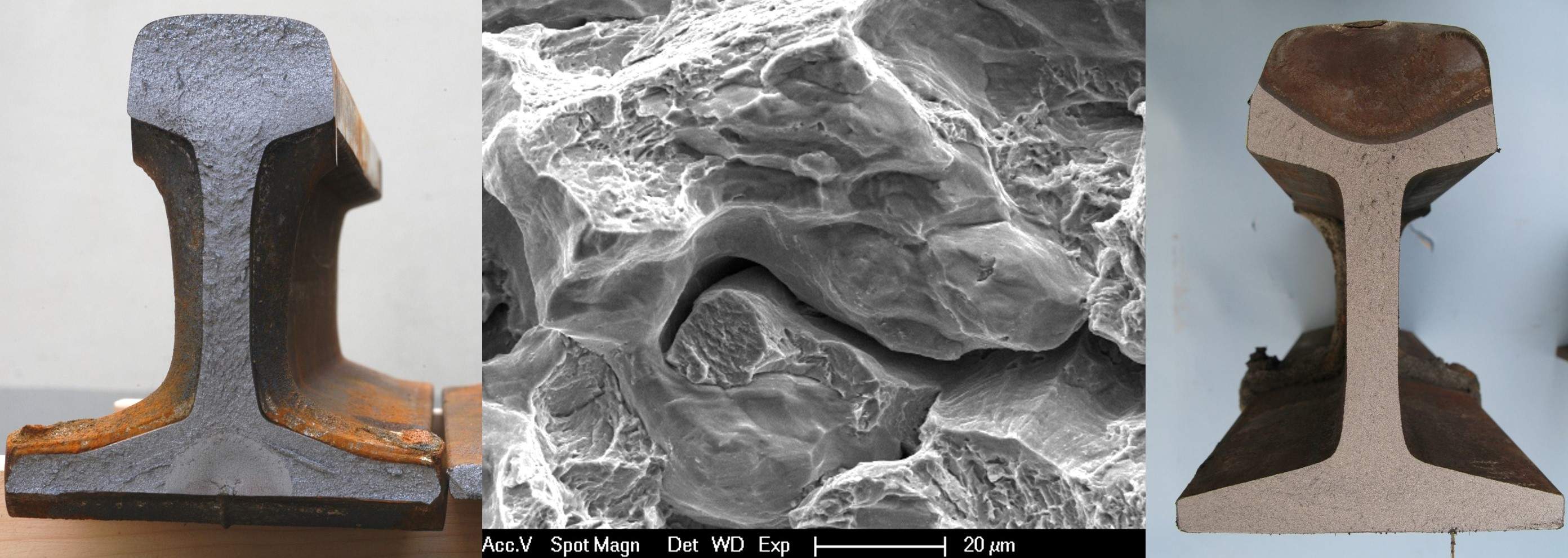

Inspection services, damage analysis and non-destructive testing

TVFA experts perform inspections on railway components, including welding joints for QA/QC, factory acceptance test or in case of damage assessments for all kinds of railway infrastructure components and systems.

As part of the TÜV AUSTRIA Group, we offer access to the whole service range, offering standard and advanced non-destructive testing (NDT) methods.

Advanced metallographic laboratory

TVFA operates a state-of-the-art metallographic laboratory.

In collaboration with the Vienna University of Technology, it offers light microscopy and scanning electron microscopy (SEM/EDX) capabilities, as well as microhardness testing and full chemical analysis.

Contact wire testing capabilities

TVFA performs approval tests and product certifications according to customer specifications.

This includes clamping lengths up to 50m, heating up to 220°C, measuring of thermal expansion coefficients and transition points, vibration tests and damage analyses of cables and wires in accordance with German standard VDI 3822.

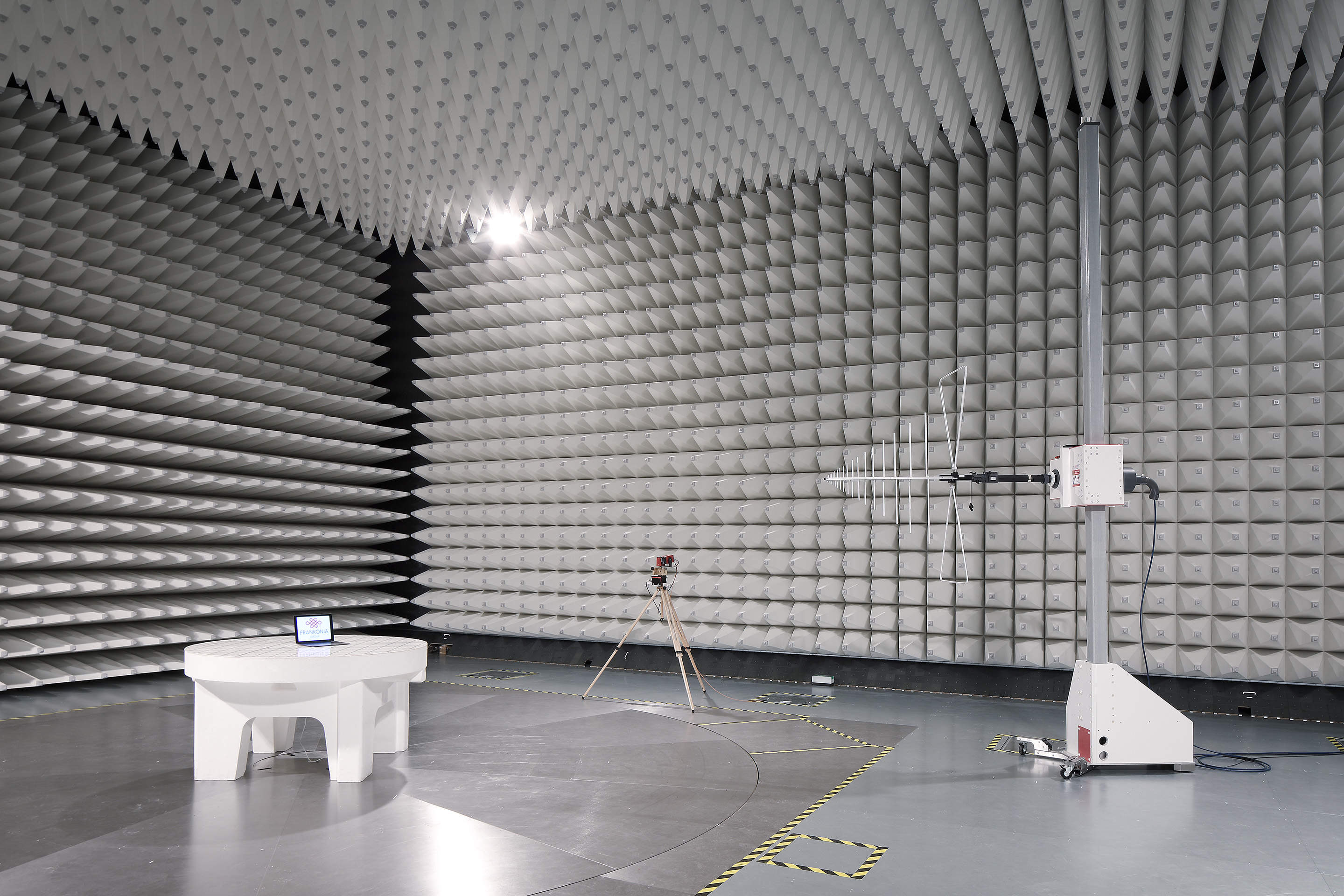

EMC and EMI services

As part of the TÜV AUSTRIA Group, we offer services in the field of electromagnetic compatibility (EMC) as an accredited and notified testing, inspection and certification body (EMC-Directive 2014/30/EC, RE-Directive 2014/53/EC, EN 50121 and IEC 62236).

We also provide mobile, open and fully sheltered sites, including a state-of-the-art test chamber.

Contact Details

Website

Email Address

Address

1230 Vienna,

Austria