KOLTECH designs and manufactures machines and devices for city rail transport and railway maintenance, such as underfloor and above floor wheel lathes, used for the reconditioning of wheel profiles of rail vehicles, and measurement and monitoring devices for wheel-set parameters.

Easy to learn, easy to use, easy to maintain

At designing of all our products, we have adopted the main rule of simple and easy learning of operating, using and servicing of the machines and at the same time of making use of the latest technical solutions.

TUP650, TUP650H, TUP650SH – underfloor wheel lathes

The underfloor wheel lathes types, TUP650, TUP650H and TUP650SH are designed for reconditioning of wheel profiles of all ranges of rail vehicles. The machining process is carried out without the necessity of dismantling the wheelsets from the vehicle.

TUP650 lathe is designed for light rail vehicles such as tramways where single-axle load does not exceed 10,000daN whereas TUP650H lathe is for applications, such as traction units of subways where single-axle load does not exceed 18,000daN. The TUP650SH lathe is for railway applications where single axle load does not exceed 30,000daN / 40,000daN.

Every model can be produced in tandem versions, with two underfloor wheel lathes located back to back that can operate two axles of one bogie at the same time.

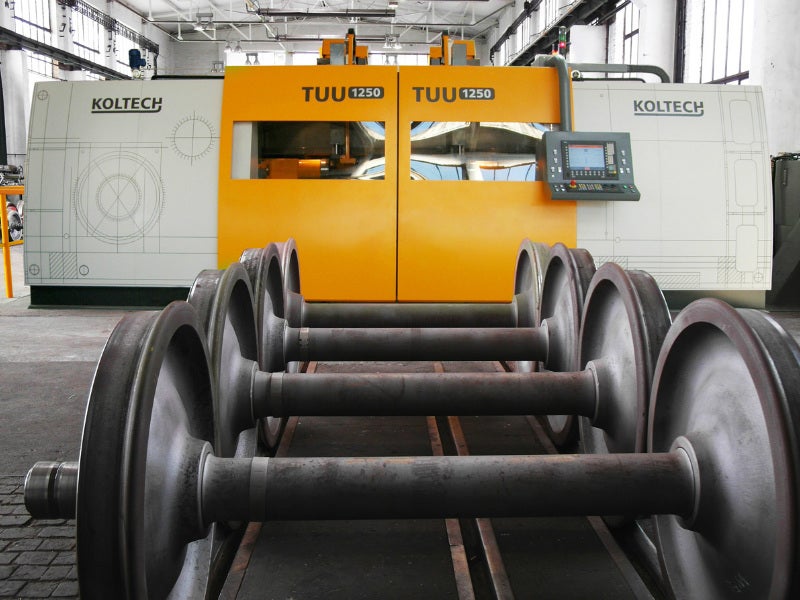

TUU1250 – above floor wheel lathes

The above floor wheel lathe type TUU with a friction drive is designed for turning of wheel profiles of rail vehicle wheelsets both the new and the used one. The loading and unloading of wheelsets from the machine can be carried out from the floor level. The wheelset is rolled in and rolled off at the front of the machine. The machine can also work in roll through system.

VIDIgo – diagnostic stations

VIDIgo is a diagnostic station designed for automatic, contactless measurement of profile and diameter of the rail vehicles. Additionally with the use of that station you can perform the measurement of back-to-back distance.

The station is installed on the rail track, for example, in tramway depots and it enables the measurement of the parameters while the vehicle travels over the station at a speed up to 15km/h during the measurement process from one approach direction VIDIgo station can be installed both in pit type foundation made in the depot floor and also in a revision channel.

VIDIgo diagnostic station can cooperate with the underfloor wheel lathe series TUP.

PZD150 – ring rolling machines

The type PZD150 ring rolling machines are special purpose devices, designed for rolling of the safety rings in the tyres of the wheelsets. They are mainly used in repair railway workshops. The ring rolling machine is a multifunctional device; it enables the rolling of wheelset of various diameters in a wide range of speeds and rolling forces of both standard and drive wheelsets.

KOLTECH is ISO 9001:2015, ISO 14001:2015 and ISO 45001:2018 certified.