With over 40 years of power supply experience, Schaefer specialises in the design and manufacturing of power converters for the rail industry. Schaefer has a commanding knowledge in solutions for on-board and trackside heavy rail applications. Controlling its own design and manufacturing allows for ultimate flexibility in developing products with an endless combination of input and output voltages. Extra rugged construction ensures long life and reliable operation in even the most demanding applications, including on-board electronics, as well as other transit vehicles, mining vehicles and switches.

Railway power conversion products

Schaefer’s experience in power conversion for the railway industry results in the market place’s most feature-packed list of capabilities for optimised rail designs:

- 36VDC, 37.5VDC, 74VDC or 110VDC

- Ultra-wide input ranges handle extremes such as the 74VDC bus

- Steady output power even during start-up or cranking conditions

- Buck, boost or isolated topology

- DC/DC, DC/AC, AC/DC or AC/AC designs

- Custom solutions, typically with no NRE

- Hermetically sealed solutions

- Natural convection or water-cooled solutions

- Extra rugged construction for the most demanding and harsh trackside and on-board environments

- Redundant configurations for longer life operation in critical applications

- Ultra-wide temperature ranges

- Lightweight, high power density for smaller package designs

- High efficiency for lower cost of ownership

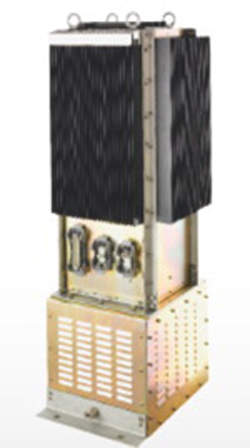

Power converters for the railway industry

Schaefer has developed numerous power converter designs to satisfy the power challenges of the rail industry. Often Schaefer can make minimal modifications to one of its standard products in order to meet a customer’s unique requirements. For more complex applications, Schaefer offers in-house design capability with quick-turn engineering results with minimal NRE charges. Schaefer welcomes the opportunity for small-scale production quantities whether it is for a modified, standard or full custom design.

Power converter solutions for heavy rail

Problem: onboard systems must be operational during engine cranking when battery voltage drops below 20VDC.

Schaefer solution: wide DC input allows for full power during cranking or at system start-up.

Problem: locomotives in yard need to be moved for service or put into operation.

Schaefer solution: dead start DC/DC energises batteries, allowing for immediate start-up of locomotive in yard.

AC/DC power supplies, DC/DC converters and battery chargers

Schaefer’s broad range of standard products, with power ratings from 50W to 22kW, are suitable for any application where robust design and high reliability are required. Schaefer offers the industry’s most complete range of input and output voltages, with a selection of package style and mounting configurations.

Schaefer’s standard products feature:

- Ultra-rugged design

- Railway-grade construction

- Suitability for harsh environments

- High reliability

- Conformal coating

Fully compliant custom power converters

Schaefer’s custom power solutions feature power supplies that are designed to meet rail-specific standards, including EN50155, EN50121-3-2, RIA 12, IEC571, as well as IEC61373 shock/vibration and RIA 13 and RIA 20 mechanical standards. Schaefer can also design to other standards upon request.

Development guidelines, arduous selection of industrial-grade components, as well as many test procedures during all steps of production, ensure the highest product quality. In addition, Schaefer follows ISO 9001 guidelines, guaranteeing continuous improvement of the product and process, especially within the turbulent market of electronic components.

From the initial concept, through the entire sales channel, each customer’s requirements are analysed by a group of leading power supply professionals, resulting in a successful individualized concept. Schaefer’s production and development departments work in concert with each other, furthering optimized progress during all project stages. It provides tailor-made solutions for both large and small quantity requirements.