The Beena Vision and Nexala range of software and devices from Trimble Rail is designed for the management of railway transport assets, including operation, maintenance and repair.

The comprehensive range of on-board and wayside monitoring solutions allows railway operators to improve efficiency, provide high-quality service and reduce expenditure. Solutions deliver intelligent asset data to passenger and freight railway operators to streamline operations and move from reactive to predictive work processes.

Trimble Rail’s end-to-end rail asset lifecycle solutions maintain rolling stock assets and improve operational efficiency through remote diagnostics, component condition monitoring, performance management and engineering asset management.

Rail asset inspection and measurement systems for preventative maintenance

Trimble Beena Vision solutions automatically record and inspect the condition of railway components, identifying potential faults before damage occurs.

The company’s wayside monitoring solutions can be used to detect faults as a method of preventative maintenance. Automated analysis of individual component data can help prevent faults developing into system failures and allow for maintenance to be planned without causing a major impact on service.

This helps minimise the number of failures across the railway network and enables efficient maintenance to be planned ahead rather than emergency repair works.

Trimble Beena Vision solutions enable time-efficient and cost-effective maintenance that is more accurate than manual monitoring methods. The lifespan of expensive railway components such as wheelsets can be optimised, with more accurate expected long-term maintenance costs by using Trimble’s range of monitoring solutions.

Rolling stock wheelset inspection and measurement

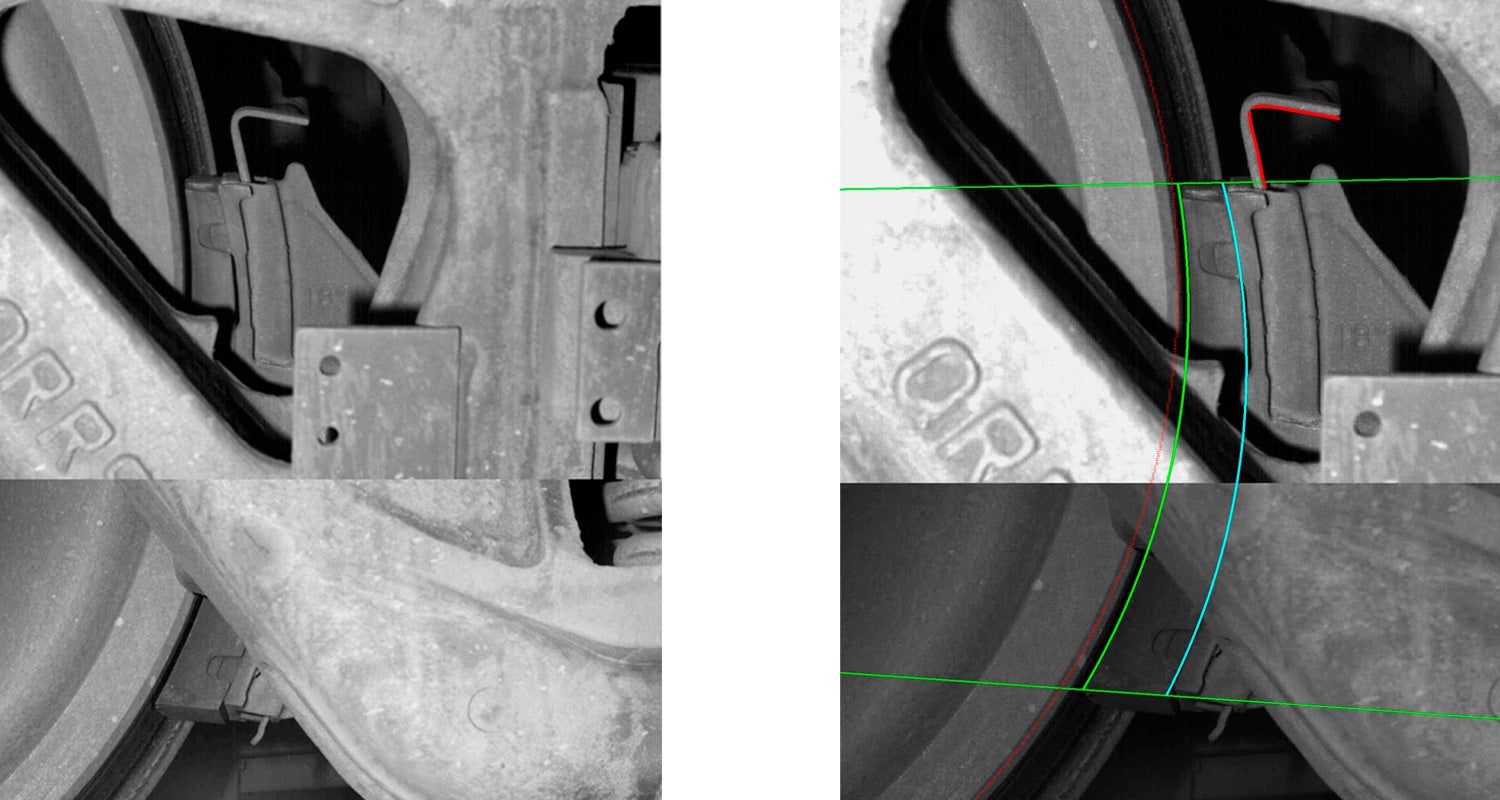

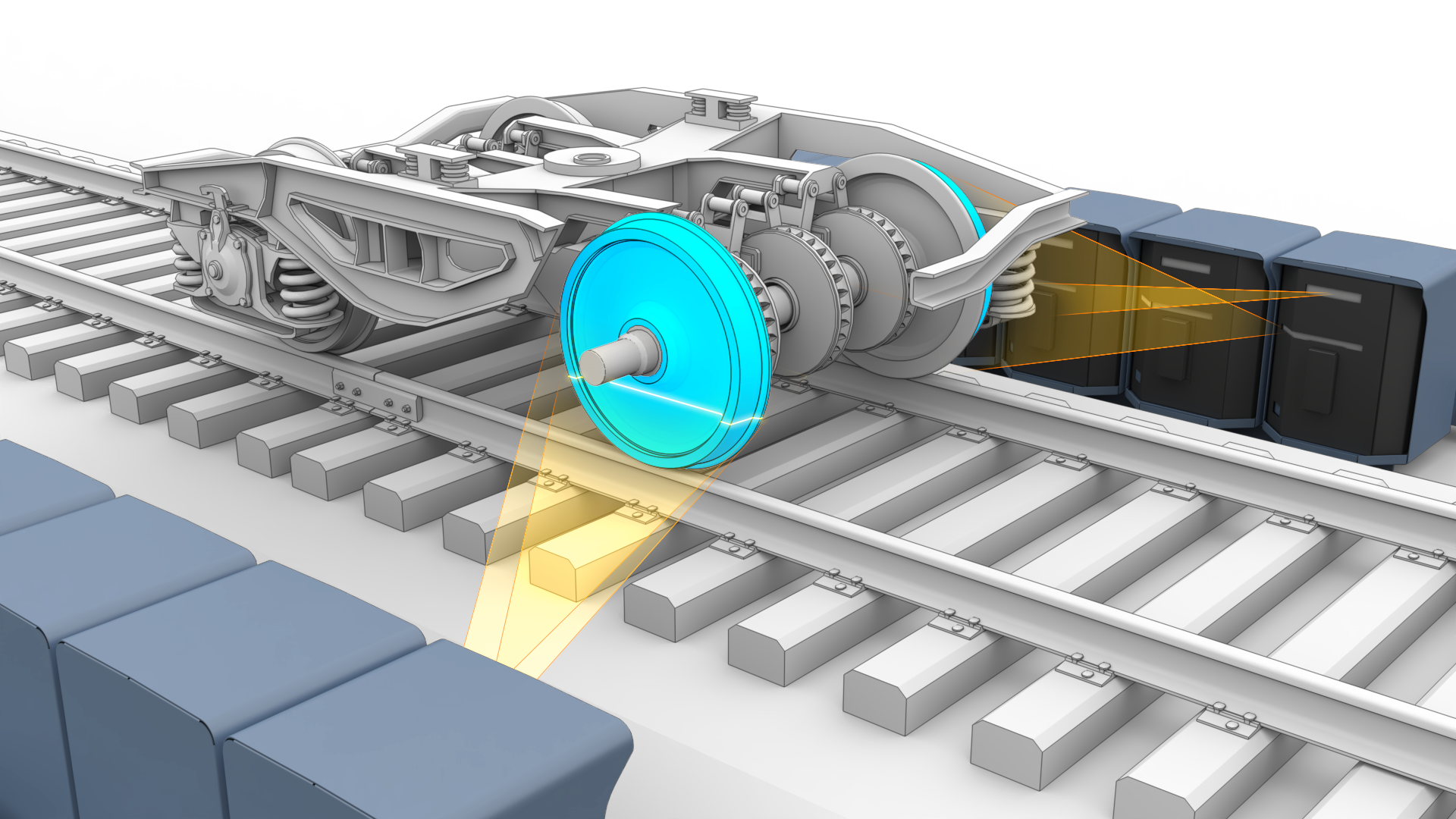

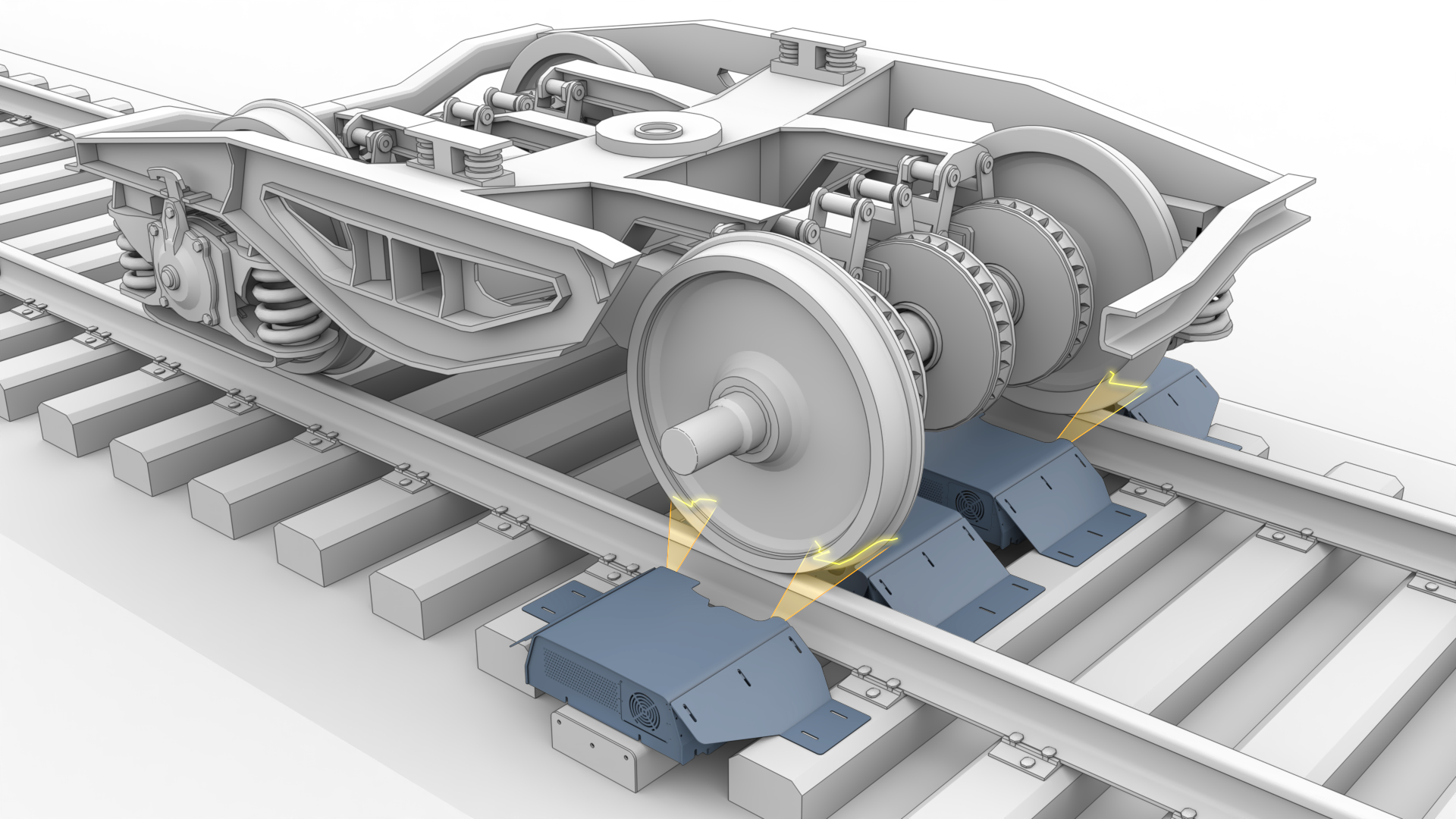

The WheelView automatic wayside system is designed to measure wheel profiles of moving trains to prevent derailing, increase the efficiency of wheel maintenance by identifying proactive maintenance practices, and reduce rail damage from worn wheels.

TreadView is an optical wheel surface inspection system that automatically assesses train wheel tread surface, flanges and plates without contact while the train is operating at normal speed.

Brake inspection and measurement

Trimble’s BrakeView automatic wayside vision-based system measures and checks brakes at mainline track speed using multi-camera fast digital imaging.

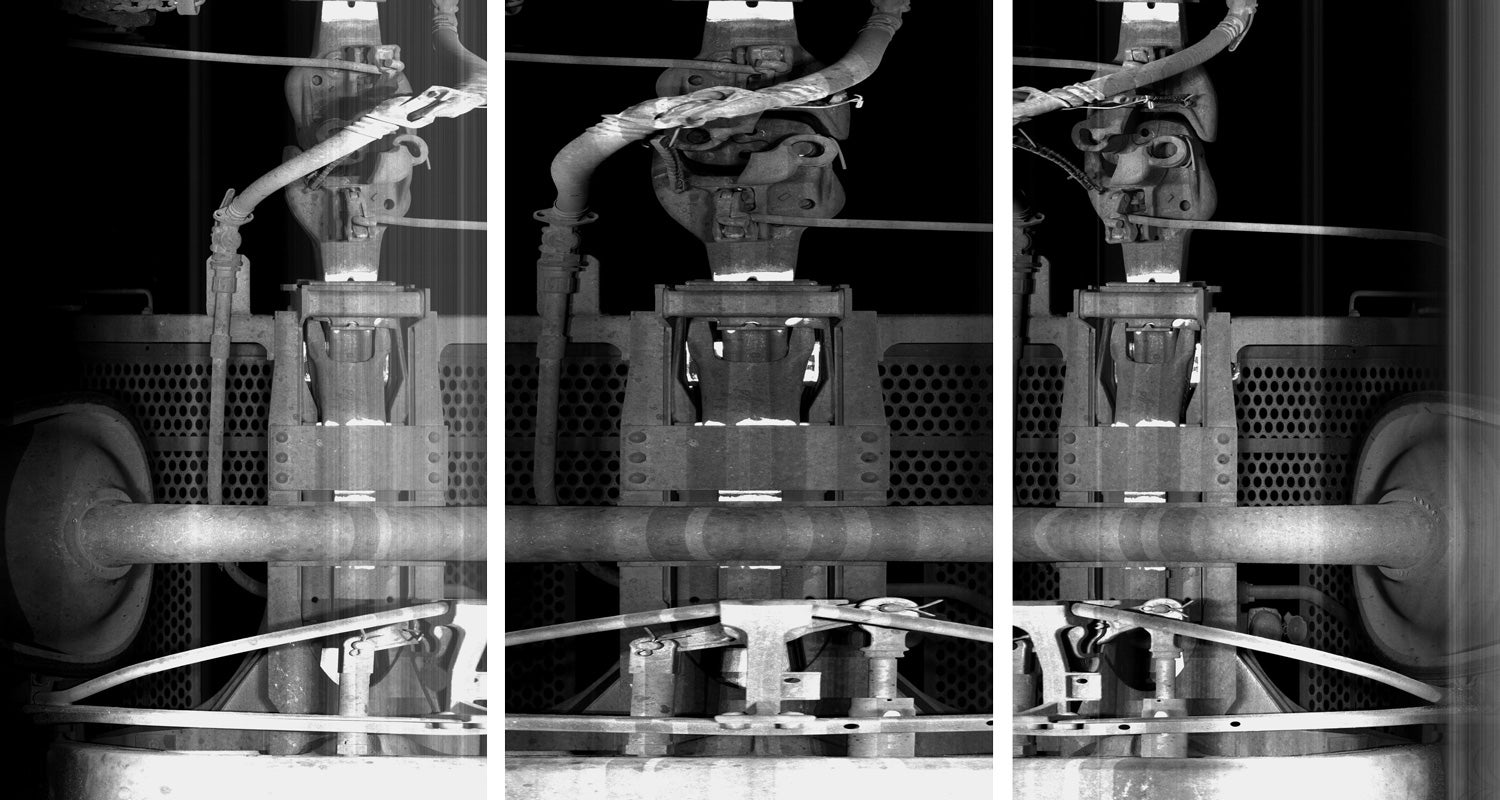

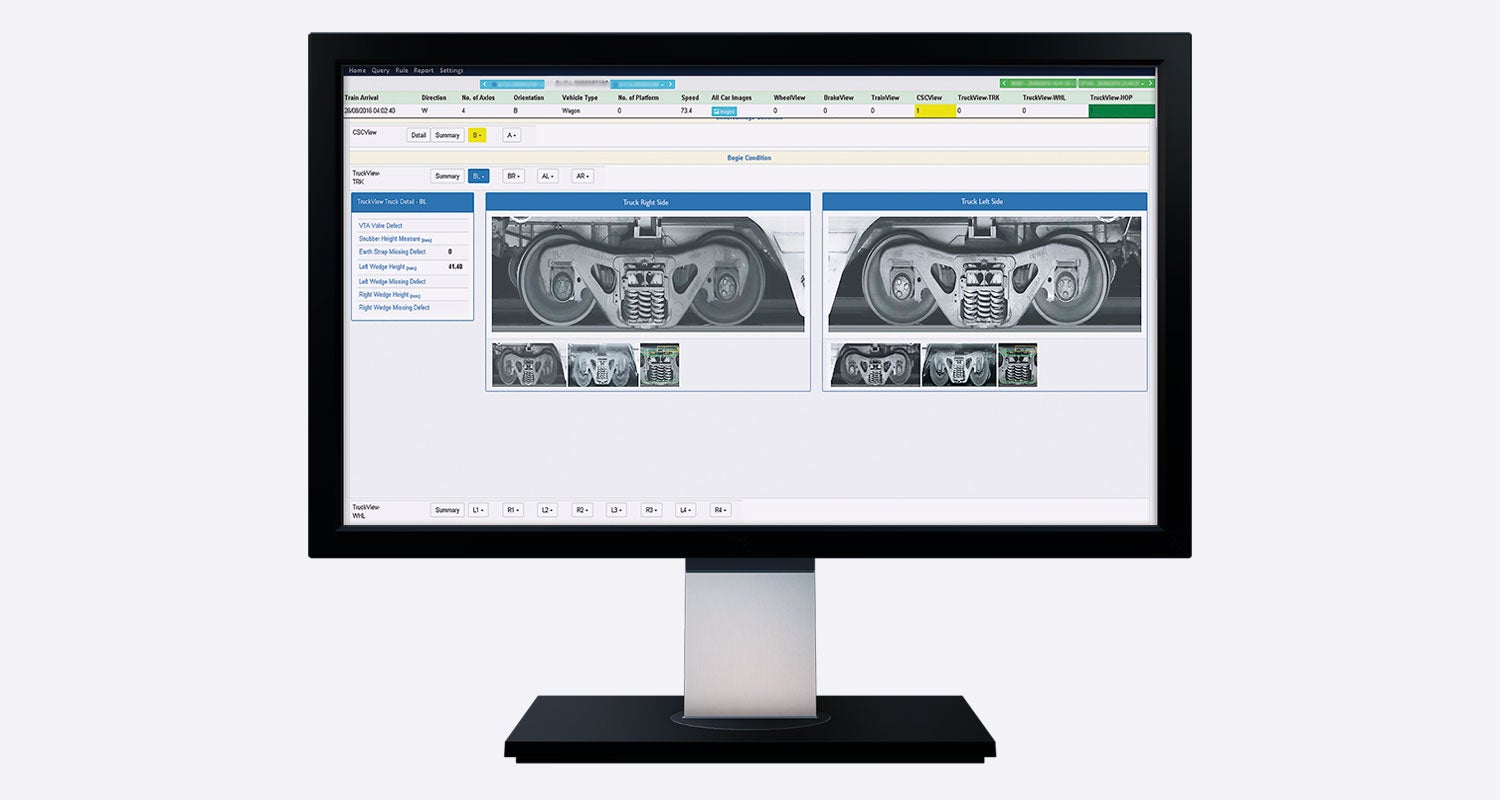

TruckView operates on trains at normal speed to monitor the condition of bogies using vision-based high-speed, high-definition imaging software.

The AOAView system is installed between the railway tie to measure the wheel angle-of-attack. The system can be integrated with automatic equipment identification used on railways across North America to identify and report on vehicle faults.

Car vision-based train inspection and measurement

AHView is a brake air hose inspection device that uses the same high-speed imaging technology to capture air hose systems on trains during normal operations.

Coupler securement mechanisms are assessed with digital line scanning using Trimble’s CouplerView to ensure there are no defects.

The Trimble CSCView solution generates high-quality images of the train undercarriage structure that are suitable for inspection.

TrainView is an automatic full scale train imaging and inspection system that images and inspects train body/roof area at mainline operational speeds.

TrainView®-LS is an automatic full scale train laser scanning inspection system that uses 3D data to inspect each car (wagon) in a train at mainline operational speeds.

Software solutions

Trimble’s Condition Monitoring Management System (CMMS) software is a condition monitoring data management platform that provides a unified environment for data from trackside detectors.

TrainWatch is a powerful virtual train inspection portal that provides a comprehensive platform for train inspectors to assess a full train using data gathered by wayside equipment.

Real-time rail fleet diagnostic solutions

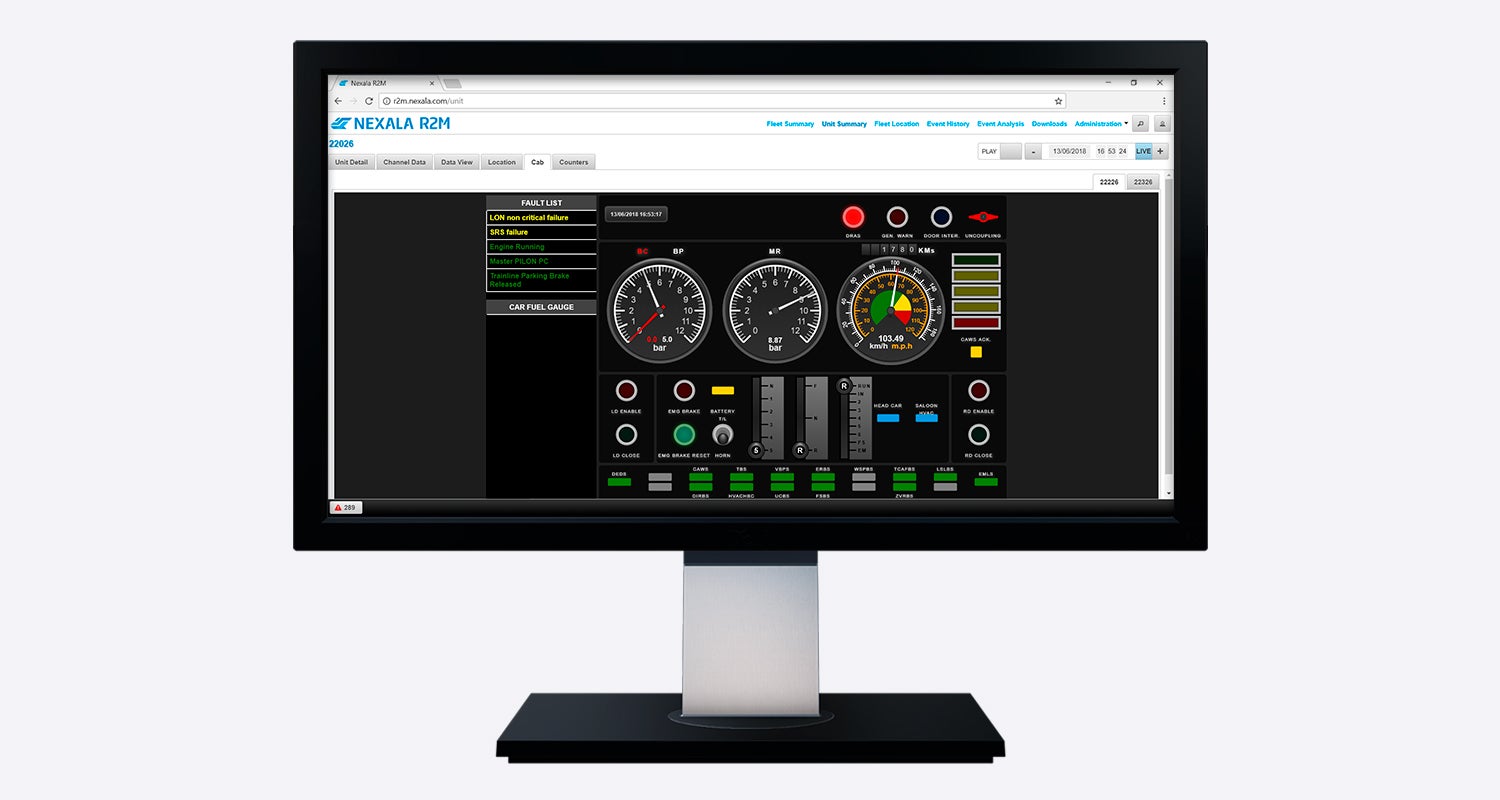

On-train sensors and Cloud-based software are used in Trimble Nexala solutions to process diagnostic data in real-time.

Rule engines automate data processing, monitoring sensor data, and firing alerts that can be actioned. Users can create and define rules for anything being monitored to suit the fleet.

Real-time remote diagnostics provide savings for engineering, maintenance, and fleet operations managers to optimise maintenance programmes, increase asset utilisation and improve fleet management.

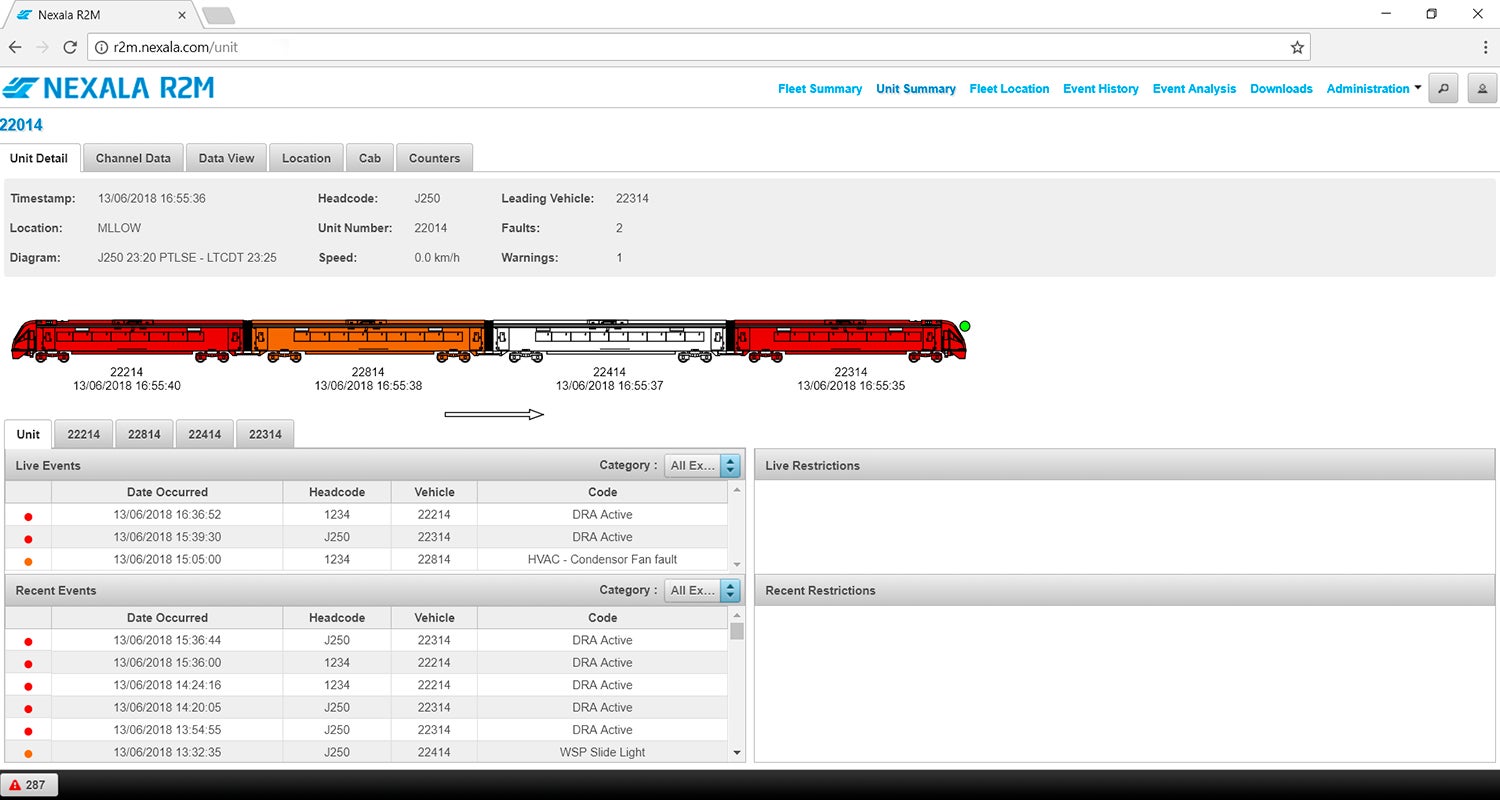

The R2M system delivers a complete status overview for the whole fleet, including specific faults and areas that may need maintenance.

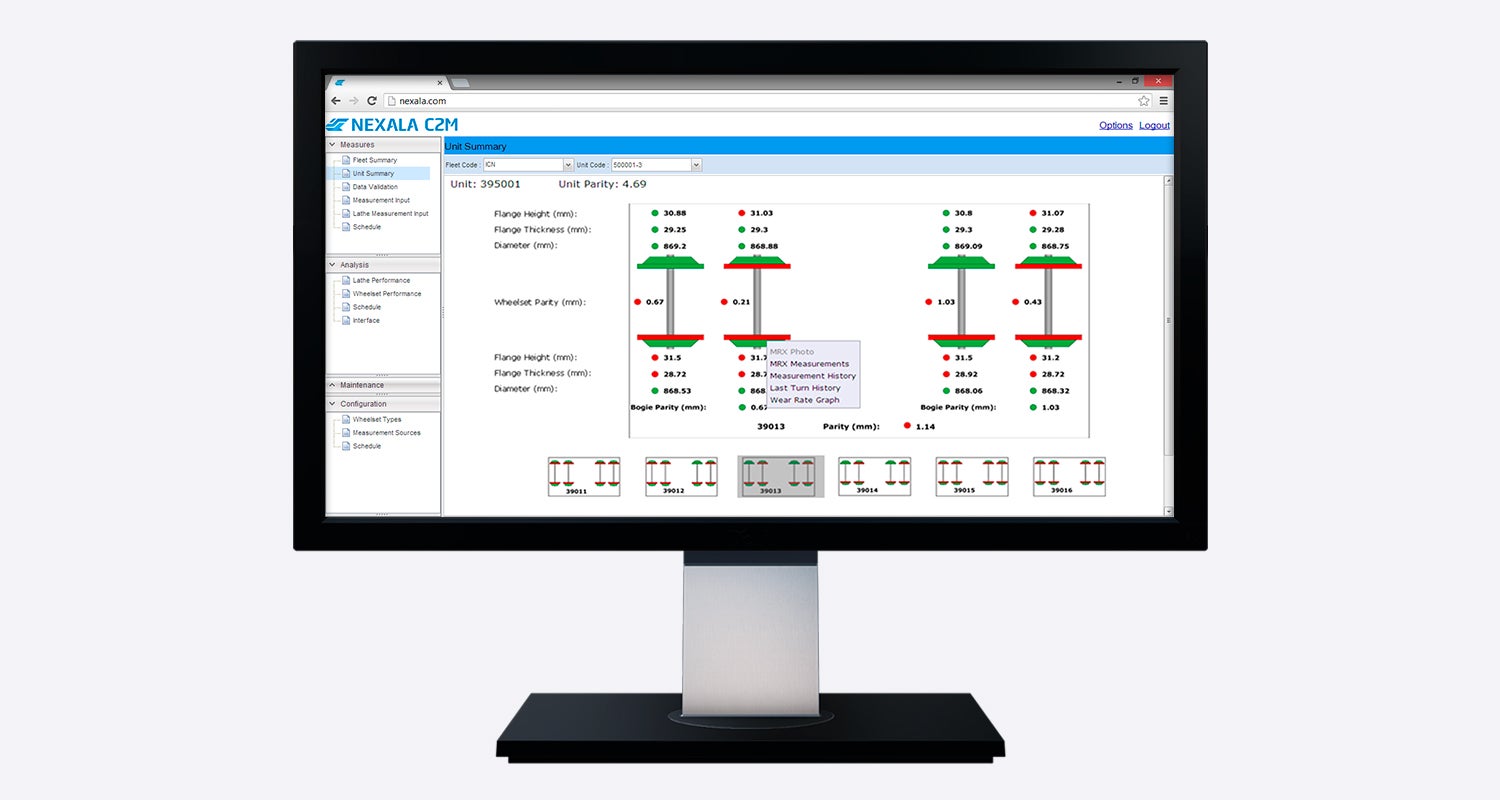

Key component condition monitoring is performed by the C2M system. It reports identified defects and wear, as well as automating maintenance schedules.

Rail industry approved, the on-board NCU control unit is ideal for condition monitoring. It is capable of linking a range of train signals and systems.

Trimble’s CAS solution is an on-board advisory system that allows drivers to view their train’s performance and remain on schedule.

Rail asset maintenance management system

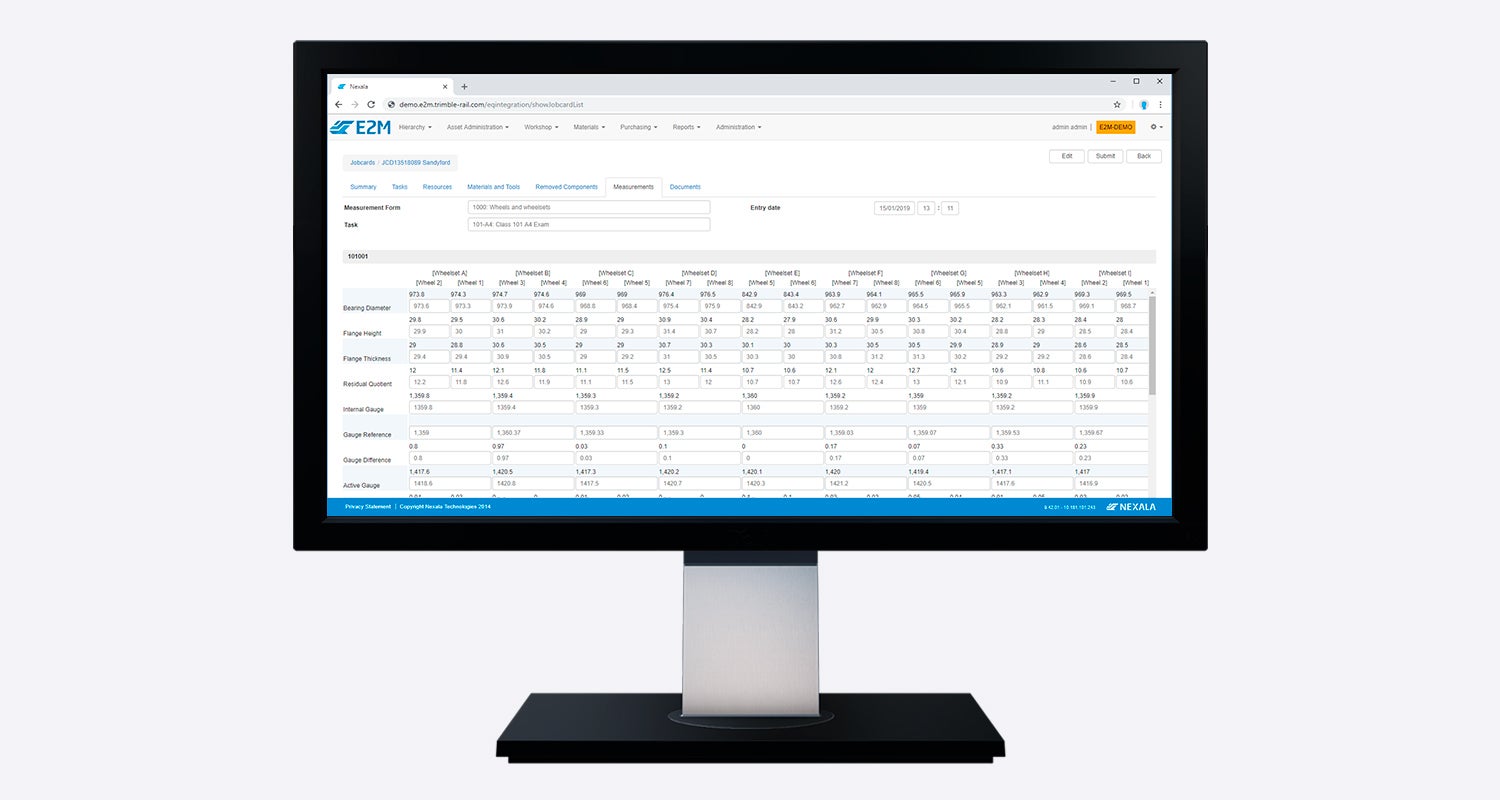

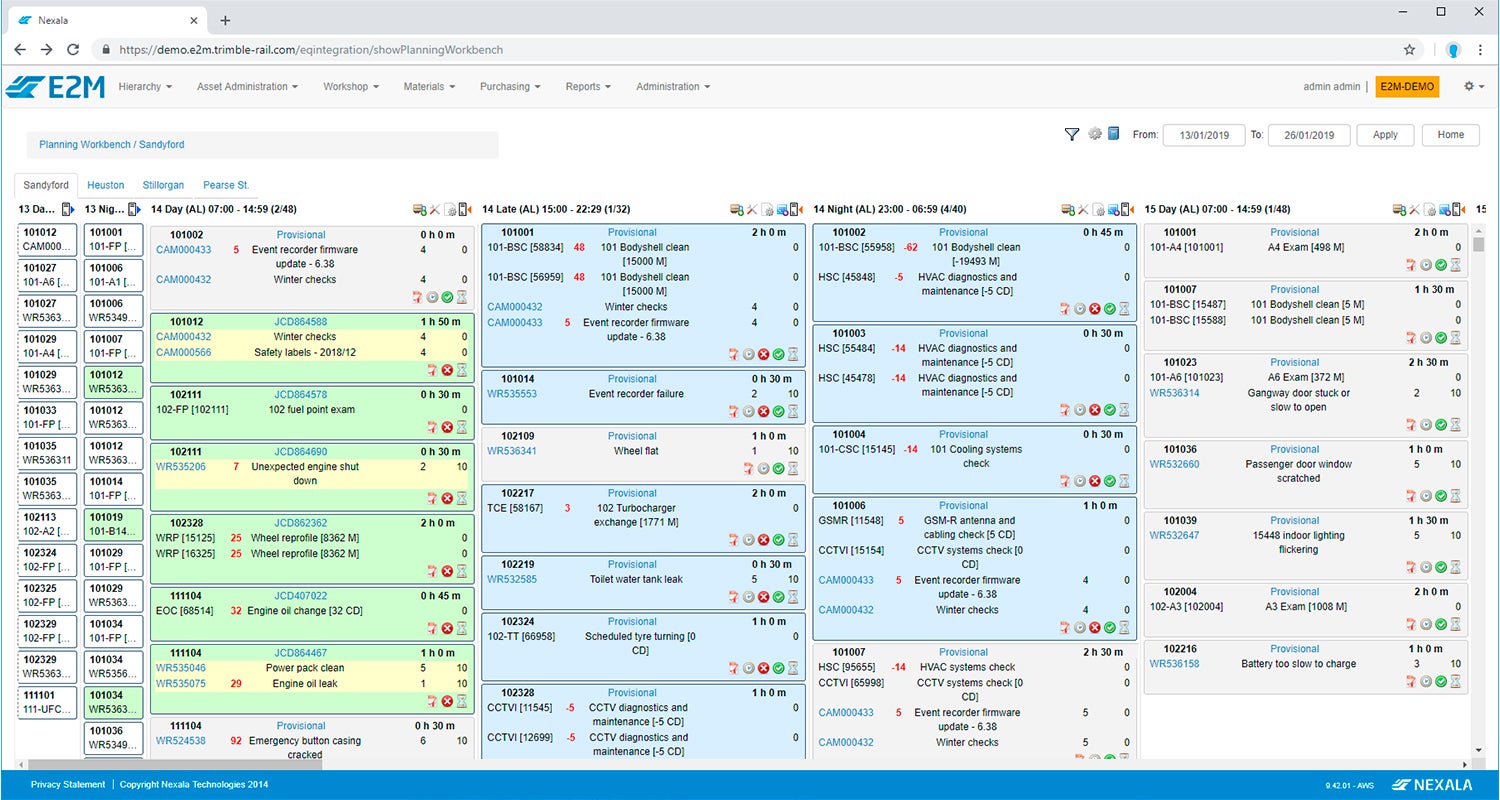

Effective engineering rail asset maintenance management using the Trimble E2M solution allows a train operating company to plan and manage an effective maintenance plan.

E2M unifies data for maintenance management to reduce data silos, as well as increasing collaboration within the maintenance team.

In-service railway performance planning and management

The P2M system is used when the railway is in-service to collect timetable, vehicle location and real-time diagnostic data to monitor performance and ensure that trains are operating on schedule.

Trimble P2M and Trimble CAS Cab Advisory systems allow for energy and fuel efficiency to be optimised through journey planning and increased driver awareness, which assists in assessing their performance.

Both systems are designed to deliver in-service recommendations to train operators when a failure occurs to minimise delays and financial implications.