Exports of agricultural products from the central western region of Brazil are seen as one of the country’s most important long-term exports, offering the nation a chance to alleviate some of its crippling national debt.

Brazil is a major player in exporting agricultural and mineral products including sugar, soy beans, meat, wood pulp and iron ore, with grain one of the most prominent cargos. The most important grain-producing region in the country takes in the three states of Mato Grosso, southern Goias and Mato Grosso do Sul, south of the Amazon River and rainforest.

Between 1980–94, exports trebled to nearly 13 million tonnes, but the region was held back from contributing more to the world’s agricultural markets by poor communications. Grain had to be transported largely by inadequate roads, over distances ranging from 1300 to 2000km. To combat these issues, Ferronorte was formed by major grain exporter Itamarati to provide a new and efficient transport corridor.

THE PROJECT

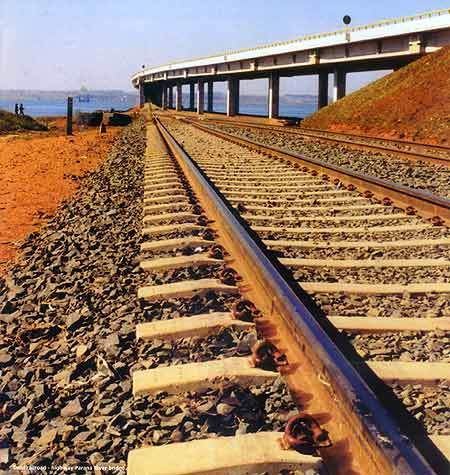

The original project started in 1992, and involved construction of long stretches of new railway, including from Aparecida do Taboado, in Mato Grosso state, to Alto Taquai, across Mato Grosso du Sul state, totalling 249 miles (400km). The first 310km section opened in May 1999, taking Ferronorte tracks into Mato Grosso state, which included crossing the Parana River with a 3.7km bridge.

However, times have changed and in 2006, following further investments in the system and increasing debts, Ferronorte – along with the other constituents of Brazil Ferrovias, Ferroban and Novoeste – was bought out by America Latina Logistica (ALL) with BNDES bank holding a 12.77% stake in return for ALL taking on the R$1.7bn debt of Brazil Ferrovias. ALL is now responsible for all operations on the Ferronorte system.

During 2005 Brazil Ferrovias invested R$253m in track upgrades and acquired a further 57 new locomotives and 650 wagons, while ALL is continuing to invest in the railway system. Between 2006 and 2009, ALL plans to invest R$2bn, including an initial budget of R$500m for new rolling stock and infrastructure improvements.

INFRASTRUCTURE

The new rail line runs through almost flat country, which has a humid, tropical climate with regular rainfall. The major obstacle faced by the constructors of the first phase was the crossing of the Parana River, near Santa Fe do Sul. The Brazilian federal government and Sao Paulo state formed a consortium to design and build a 2.6km double-decked bridge, including a navigation channel for barges.

There are tight infrastructure requirements elsewhere, with a maximum grade of 1° in either direction, and a curve radius of no more than 650m. Six million cubic metres of earth were estimated to have been moved during construction.

Five concrete pre-stressed ballast deck bridges were constructed – four crossing rivers, and the fifth a road. The railway will also pass under three existing roads.

Further plans for expansion are now on the cards, although the new owner ALL is concentrating on improvements to the current network first.

ROLLING STOCK

Ferronorte invested heavily in new locomotives with more than 100 General Electric diesel-electric locomotives being bought to power its trains. Locomotives run in pairs when hauling the staple grain services. Ferronorte’s fleet has now been integrated with ALL’s own locomotives and rolling stock. ALL now operates 960 locomotives and 27,000 wagons in South America.

Soya bean traffic is carried in a new fleet of aluminium-bodied wagons, built in Brazil by Maxion under licence from parent company Johnstown. Before the new locomotives were introduced, Ferronorte used a fleet of second-hand General Electric locomotives, adapted from 1000mm to 1435mm gauge for their new use.

SIGNALLING/TELECOMMUNICATIONS

Initially, a manual block system is being used. Base radios are installed along the length of the first phase, controlled by a dispatcher in the control centre.

A train is given permission to occupy blocks along its route before it starts its journey, and the dispatcher has computer software which protects against conflicting train movements.

A point detector interlocked with approach signalling, installed ahead of the switches detects their position and gives train drivers a ‘go’ or ‘stop’ signal, depending on their position. There is scope for this system to be integrated into a fully computerised train control system in future.

THE FUTURE

Future extensions will take the railway to Cuiaba, also in Mato Grosso, from where a divergence is planned, with routes running north-west to Porto Velho, in Roraima state, and north to Santarem (in Para state), where it will link with existing rail lines in the Amazon River bay.

Ferronorte sees construction of the new railway as a catalyst for unlocking the potential for grain shipments from the area it will serve.