French global rail technology and solutions company Pandrol hosted a Mongolian delegation at their Worksop, UK site, with the aim of fostering a closer bilateral relationship.

The delegation consisting of 45 Mongolian representatives and parliamentarians is visiting the UK from 18 June to 24 June 2023, seeking to strengthen international cooperation and collaboration in the railway industry.

This visit from Mongolia follows a long history between the two nations which includes the 2019 agreement overseeing Pandrol’s long-term partnership agreement to supply rail fastenings in Mongolia and Pandrol’s recent work on the Tavantolgoi–Gashuunsukhait railway.

On the British Embassy-funded trip, the delegation will explore UK expertise across the rail industry, exploring the various solutions which underpin the rail industry.

Steven Forrest, site director at Pandrol, emphasised the impact the visit will have on both nations: “Pandrol is honoured to host the Mongolian delegation and looks forward to facilitating meaningful discussions and interactions during their stay.

“We believe this visit will create a lasting impact and lead to long-term cooperation, benefiting both nations and contributing to the advancement of the global rail industry.”

Nyamdavaa Buuvei, Head of the Foreign Corporation Division, Ministry of Road and Transport noted: “The visit was very exciting, it was unique compared to previous visits because the vising delegation consisted of professionals working within the industry and those responsible for the track infrastructure.

“It was very informative to see how the fastenings are manufactured and how the quality assurance is guaranteed.”

For the Tavantolgoi–Gashuunsukhait heavy-haul railway project, which covers 240km of track, the Pandrol team were able to offer versatile and reliable welding solutions, with enhanced virtual training and providing an automated welding system- Electric 230V High Flow Preheater (HFP).

Pandrol told Railway Technology the project was a success: “Using the HFP ensured completed welds were consistently better quality, more accurate and highly reliable.

“The solution was delivered purely to help the teams in Mongolia, offering peace of mind, confidence and assurance for welders without experience of oxy propane methods. The coaching we delivered allows track workers to preheat effectively with very little training.”

The rail solutions company aims at boosting the sustainability of rail infrastructure through their electrification processes and introduction of products such as the floating slab mats providing cost-effective and environmentally friendly options.

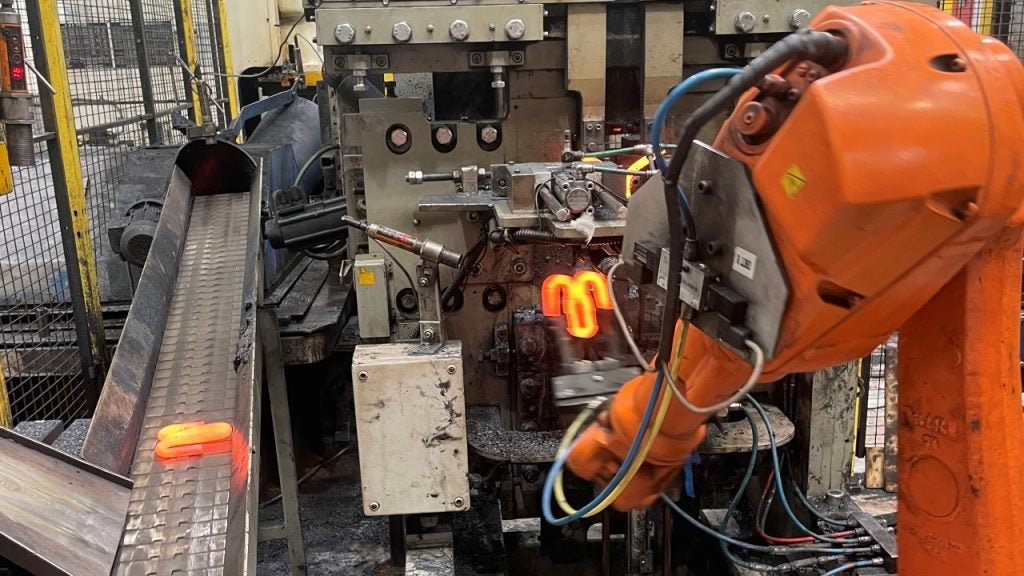

The Pandrol Worksop factory oversees the manufacturing process for rail fastenings and clip insulators, which features electrification of advanced robotic manufacturing and is suitable for heavy-haul applications.

With Mongolia being one of Pandrol’s “biggest strategic markets”, the introduction of the electric furnace used to create the Mongolian clips was significantly more efficient than the usual 1000-degree gas furnace, according to Pandrol UK QSE director Paul Mitchell.

Aligning this to Pandrol’s track for a green future, it was able to decrease its annual emissions as a whole between 2018 and 2020, from 88,522 tonnes to 49,312 tonnes of CO₂ equivalent.

In addition, the Pandrol team includes a product support crew that has been directly deployed to Mongolia to assist the employees in placing the product on their tracks.

Pandrol UK product support engineer Radoslav Korabsky told Railway Technology about his experience in Mongolia, the mix of automation and manual applications across the rail industry and said how moving to an automated system would increase efficiency.

Korabsky’s first time on a Mongolian project was in 2017, teaching Mongolian rail workers how to assemble and maintain the 27km heavy-haul petroleum line. Pandrol were able to assist by offering two of their track machines.

Furthermore, Korabsky highlighted that human sources are more “expensive” and seem to predict a future move towards automation across the industry, especially due to Mongolia’s sparse population of 3.5 million inhabitants.