During Hydraulico’s 75-year history, the company has produced more than 4,000 presses for customers worldwide. A market leader in the design and production of advanced hydraulic presses, it recognises the need for presses that are part of a full production system.

Hydraulico uses the latest technology, robotics, software solutions and computer-based automation to build customised, cost-effective products. The company’s innovations help to reduce costs and lead the way to a more streamlined and efficient production.

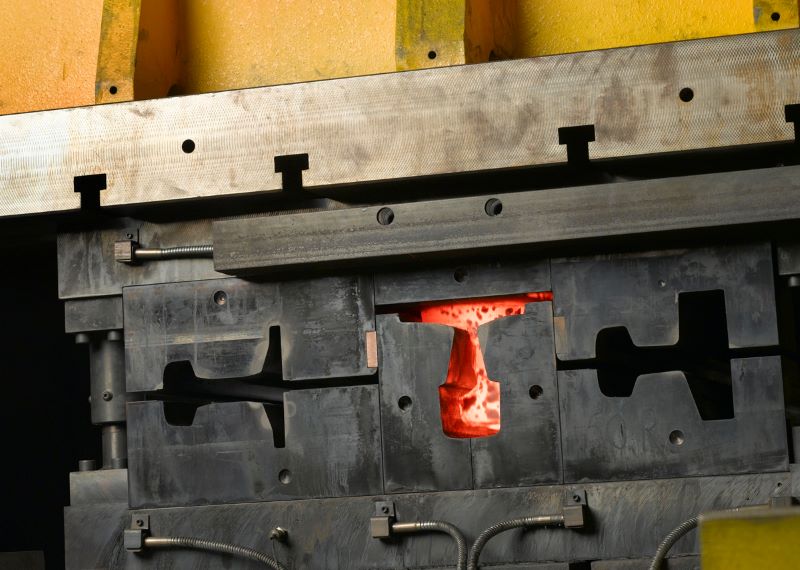

The structure of the steel can change during the hot forging of asymmetric to symmetric rib-web shaped steel and its overall properties can alter dramatically during the process. Additionally, the so-called ‘hazard zone’, which is the transition zone between the cold and the hot part of the rail, can drastically lower the hardness of the rail material.

Hydraulico has worked intensely to refine the technologies involved in transition forgings from asymmetric switch rails to the symmetric rail section. With the aid of detailed fine element method (FEM) analysis, the company has learnt how to simulate the flow of steel in virtual forging operations by carefully studying the behavior of steel in controlled conditions. This leads to a narrower hazard zone and very little drop in hardness levels.

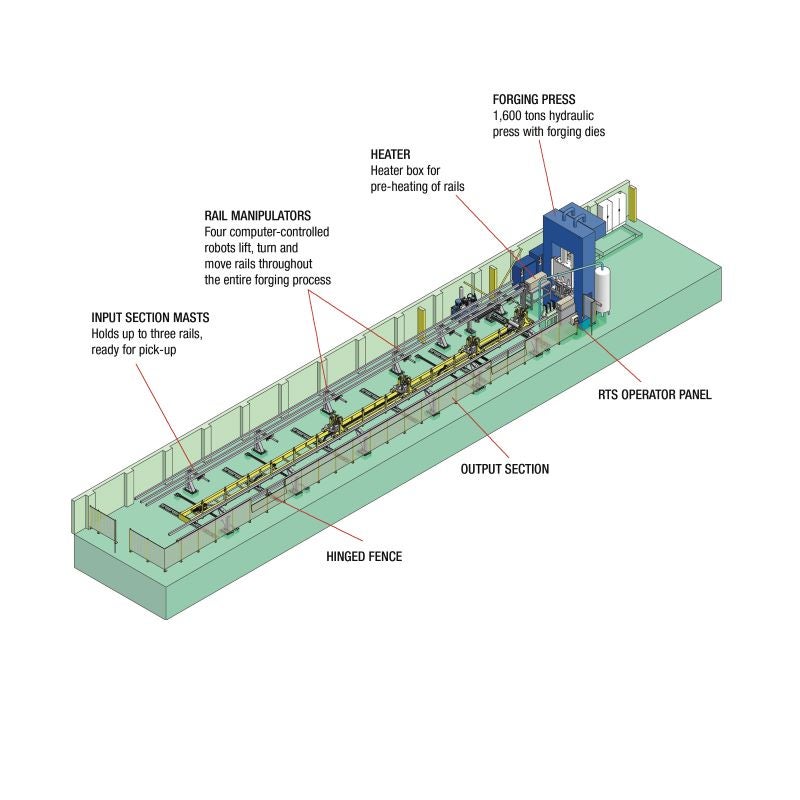

Advanced rail forging lines, rails and switches

Hydraulico offers a complete solution, including a 5,000t press with specially developed dies and an advanced computer-controlled handling and manipulating system that boosts productivity for rail manufacturers worldwide.

Benefits of the advanced rail forging line include a 75% reduction in manpower, 65% decrease in milling and a saving of more than 50% in energy costs. The product also saves time and energy in post-heat treatments.

The line perfectly produces 4-8 forged rails an hour, which is an impressive productivity rate when compared with the 1-2 rails an hour of many existing systems. In addition to the time savings in machining, capacity during the milling process is also increased.

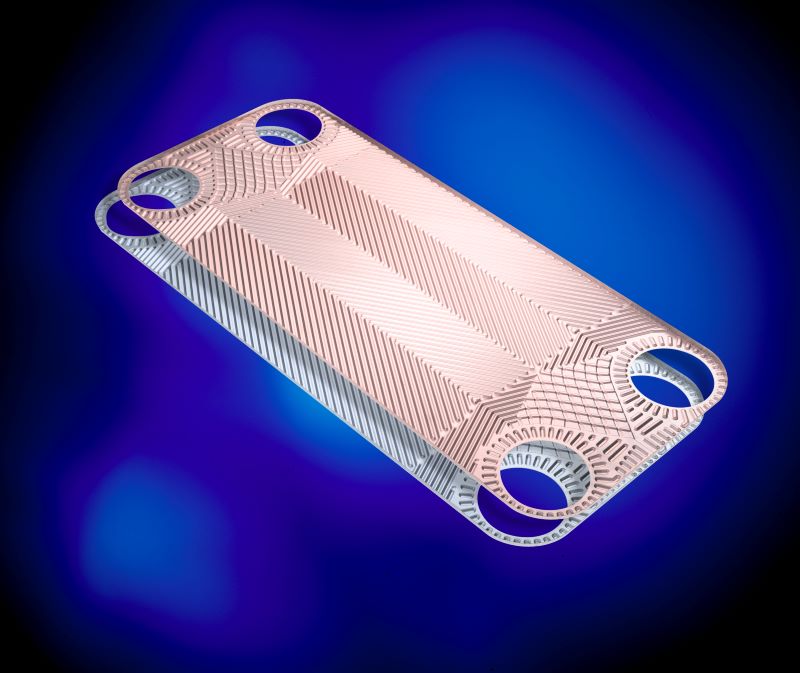

Deep drawing presses and electronic shimming

Hydraulico’s state-of-the-art presses are unmatched in efficiency. Well-designed, durable and versatile, presses range in capacity from 100t to 10,000t and customised presses are available for specific client requirements.

The company also has intelligent technologies to improve deep drawing capabilities, known as electronic shimming, which lowers scrap rates, facilitates production control and allows for quick and easy tool changing.

Die forging optimisation tools

To meet the specifications for high-speed train rails, it is crucial to avoid any wrinkling, shrinking or lack of filling of the forged shape. The information gained from the FEM analysis is imperative when designing the forging dies. Developed computer simulations clearly show the performance of the dies and the necessary forging parameters.

The advantages include an improved performance of the forging operation, an extended die life and significant costs savings in testing and commission. The design also allows for a fast changeover to a new product for the complete forging line, including dies change, leading to higher productivity.

Stamping, forging, upsetting and extrusion products

The Hydraulico STP series is designed and built to meet the highest demands for stability, productivity and flexibility. The range features the newest preforging / upsetting press technologies by Hydraulico, and offers great flexibility and extreme precision required in the aircraft industry.

The two-side forging cylinders are servo-controlled, have a precision greater than + / – 0.1mm and move with a speed of up to 120mm/s.

Hydraulico has previously built a number of customised presses for the extrusion of finned, round or hollow profiles, which can be extruded in steel, titanium or aluminium alloys.