ITB-Tradetech develops unique mobile laying machines that create twin-block concrete sleepers for railway tracks. The machines, which to date have produced more than ten million twin-block sleepers across four continents, work on the principles of instant de-moulding, quality control and extreme efficiency.

ITB-Tradetech products are flexible and can produce sleepers for various gauges and types of fixations, while installation is simple and machines can be easily relocated.

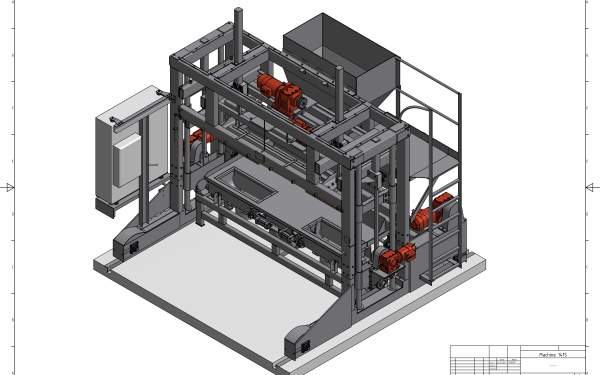

Railway sleeper moulding machines

The VDH-015 sleeper moulding machine has been designed for local production of high-quality concrete twin-block sleepers. This enables the company to offer an attractive concept for users who want mobility, simplicity and reliability.

The entire manufacturing process has been optimised to reduce local production cost, which includes equipment, raw materials and labour.

Further operational data for the VDH-015 sleeper includes:

- A minimum output of between 20-28 sleepers every hour

- A mould lifetime of 500,000 sleepers

- The ability to run on rail or swinging wheels

- Completely self-operating

Technical advantages of the VDH-015 moulding machine include:

- High adaptability to all varieties of sleepers, including sleepers for trains, trams and undergrounds, rail gauge, sleeper dimensions and different fastening systems, such as pandrol, nabla and vossloh

- Non-stop mould vibration and simultaneous mechanical compaction during production

- Constant quality throughout the product, including resistant concrete

- Instant de-moulding and dimensional control

- Perfect alignment for shoulders and inserts

- Low production investment outlay

- Easy operation

- Proven safety and experience

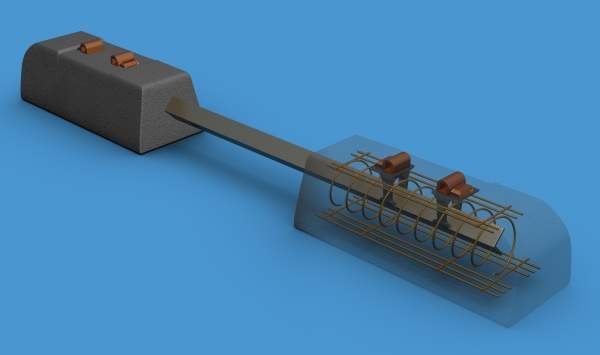

Reinforced concrete twin-block sleepers

The ITB-Tradetech twin-block sleepers are made of reinforced concrete, which means that there is no pre or post-tensioning, while the manufacturing process doesn’t require accelerated curing for concrete. Blocks are linked with a connecting bar made of steel with a high carbon and manganese content.

International design standards

The ITB-Tradetech twin-block sleepers are designed according to international standards, including European (EN), American Railway Engineering Maintenance-of-Way Association (AREMA) and International Union of Railways (UIC), amongst others.

Twin-block sleepers for freight, passenger and high-speed trains

The twin-block sleeper is suitable for urban transport, freight trains, passenger trains, high-speed trains and heavy haul trains, and boasts a vast array of advantages.

Performance advantages include the following:

- High mechanical resistance of concrete

- High flexibility of sleepers, due to the steel tie bar’s support of irregular loading and its ability to absorb shocks

- Avoidance of the undesired effect of negative bending

- High ballast centre point, which means that there are no balancing sleepers

- High precision track gauges

- High lateral stability

Facility and convenience advantages include:

- Lower weight and smaller dimensions for easier handling and transportation

- Suits all rail fastening systems and track types

- Easy set up of rail fastenings

- Simple maintenance

There are a number of cost advantages, such as:

- Low track maintenance cost

- Ballast saving

- Low investment on production equipment

Local technology transfers and partnerships

ITB-Tradetech assists with the full technology transfer for its local users, meaning that customers will feel supported at all times and never out of depth.

Some of the features of the local technology transfer include:

- Tailor-made sleeper production unit design

- Supply of all production equipment

- Sleeper design as per international standards

- Supplier of production plant, sleepers, fastening systems, rails and welding system

- Equipment installation and commissioning

- On-site training

- Continuous sales support

ITB-Tradetech also welcomes opportunities to partner with its customers in a number of different capacities that help to deliver the perfect sleeper solutions, such as technology licensing, joint ventures and alliance agreements.