Blaschke Umwelttechnik specialises in the design, manufacture, and installation of high-quality turnkey exhaust extraction systems for railway maintenance depots.

Solutions are adapted to the client’s specific needs and designed to capture, extract, and remove harmful diesel engine exhaust emissions (DEEEs) from locomotives and railcars during maintenance or servicing.

Blaschke Umwelttechnik is dedicated to protecting employees from exposure to dangerous airborne substances, and to supporting employers to meet their legal safety and health requirements.

Solutions to control the exposure to diesel engine exhaust emissions

DEEs are an important health and safety issue in workshops where locomotives and railcars are running indoors during repair and maintenance procedures. Short-term exposure may cause different irritations whereas exposure over a long period may increase the risk of cancer. The International Agency for Research in Cancer classified DEEEs as carcinogenic to humans in 2012.

Employers have statutory health and safety responsibilities. In the EU, a legal framework is given by OSH (Occupational Safety and Health) directives that are transferred in national laws and complemented by specific national standards and regulations, such as the German TRGS 554. The most relevant pieces of legislation in the UK are the HSW Act and a few other regulations such as the Control of Substances Hazardous to Health Regulations. Particular information can be found in the HSG187 guidance from the Health and Safety Executive.

With its exhaust extraction solutions, Blaschke Umwelttechnik offers engineering systems to avoid exposure of workers to DEEEs in railway workshops.

Special exhaust extraction systems for locomotives and railcars

Blaschke Umwelttechnik’s systems are at source exhaust extraction solutions. They are designed to capture the dangerous airborne substances directly from the exhausts before they may be released into the workshop. It is the safest method to control the diesel engine exhaust emissions and an effective way to reduce costs by fewer sick days, less energy needed to heat and lower building and equipment maintenance.

A typical Exhaust Extraction System is composed of a hood to collect the harmful exhaust fumes, an extraction unit, ducts to channel the exhaust fumes, and an extractor fan. The fan ensures that the harmful exhaust emissions are extracted and discharged outside the workshop. Remote control systems and programmable logic controllers allow for easy operation.

All extractor fans used by Blaschke Umwelttechnik comply with the efficiency requirements for electric motors defined by the EU Commission Regulation 2019/1781.

Stationary exhaust extraction systems

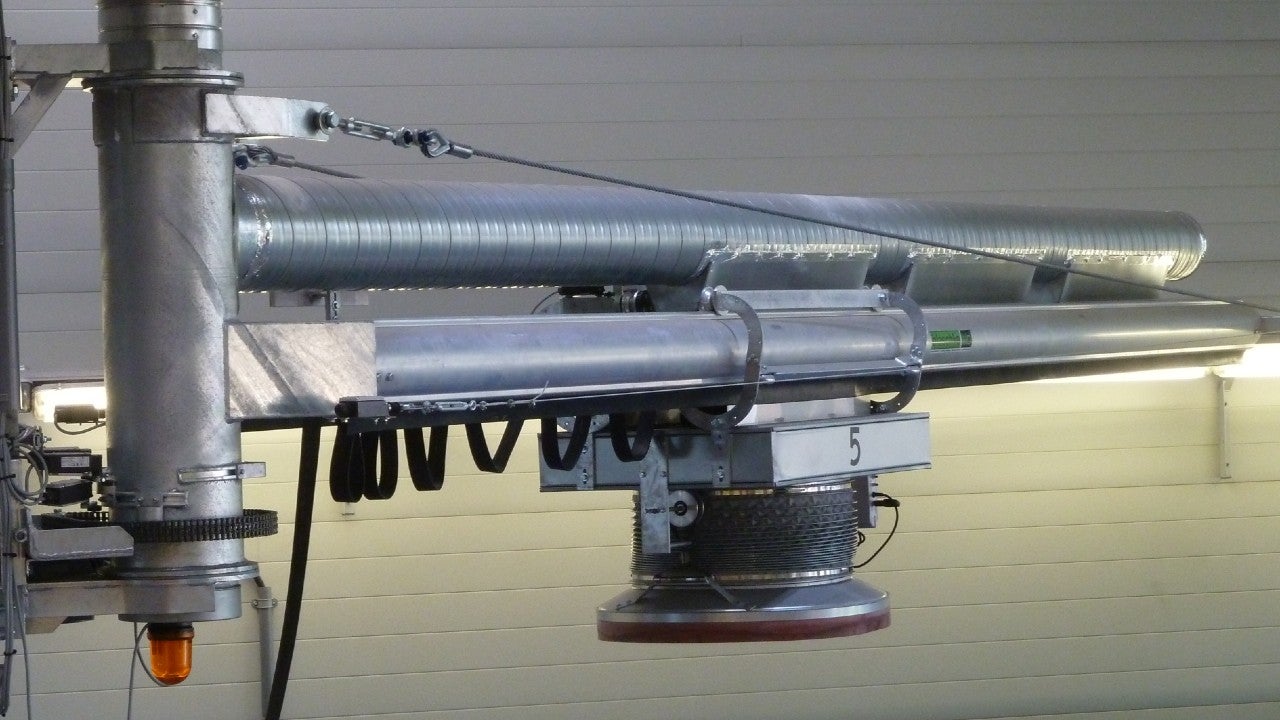

Stationary exhaust extraction systems are available in two types: a capture unit fixed to the roof construction of the building or swivel arms that may be free-standing or attached to the building structure.

RailPoint is an economical and space-saving solution, when only one train type or a specific train configuration is regularly serviced and if the trains stop always at the same place. It features a motor-driven capture hood that may be lowered over the exhaust pipe of the vehicle by remote control. Fully automatic lifting and lowering operations of the hood are also possible.

The proven Swivel Arm solutions are more flexible and are suitable for workshops equipped with overhead cranes or overhead lines. Swivel arms are available in lengths of up to 12m and in different forms and can be operated manually or automatically.

Mobile exhaust extraction systems

Removing diesel exhaust fumes at the point of release is a big challenge. It is even bigger when a range of different trains are serviced in one railway maintenance depot.

Be it an existing or new workshop, Blaschke Umwelttechnik always finds a solution tailored to the individual customer needs, starting from two basic mobile Exhaust Extraction solutions: Swivel Arm Systems and Overhead Systems.

Wall-travelling arms are the basis to design individual flexible solutions capable to reach the exhaust outlets of locomotives and railcars at any place.

More sophisticated solutions consist in exhaust extraction bridges that may use runways of existing overhead cranes or self-supporting suction rails which are part of the exhaust extraction system. They make it possible to easily reach the exhausts of very different rail vehicles, from freight trains to multiple units or track laying machines.

About Blaschke Umwelttechnik

Founded 45 years ago, Blaschke Umwelttechnik has turned into one of the leading European manufacturers of Exhaust Extraction Systems for diesel railway vehicles within railway depots.

Numerous well-known national and international train companies and vehicle manufacturers rely on the special and longstanding expertise of Blaschke Umwelttechnik.

The company’s product range includes individual, cost-effective, and user-friendly exhaust extraction solutions for fire and rescue stations, for utility, construction, mining and military vehicle workshops, and production plants.

With Blaschke Umwelttechnik you choose an exhaust extraction solution from a single source: from design and manufacture to installation, commissioning, testing, and training.

If we can help you make your workplace safer and more efficient, please do not hesitate to send us your business enquiry using the form above.