Western Dedicated Freight Corridor (DFC) is a broad gauge corridor under construction that will connect Delhi and Mumbai, the national and business capitals of India. In October 2006, the Indian Government established a dedicated body, the Dedicated Freight Corridor Corporation of India (DFCCIL), to carry out the project.

The western DFC will separate freight and passenger traffic to increase the speed of freight movement. It will be used to transport fertilisers, food grains, salt, coal, iron & steel and cement.

The project will eventually be linked to the Eastern DFC to form four hubs known as India’s Golden Quadrilateral including Delhi, Mumbai, Chennai and Kolkata.

Western dedicated freight corridor route details

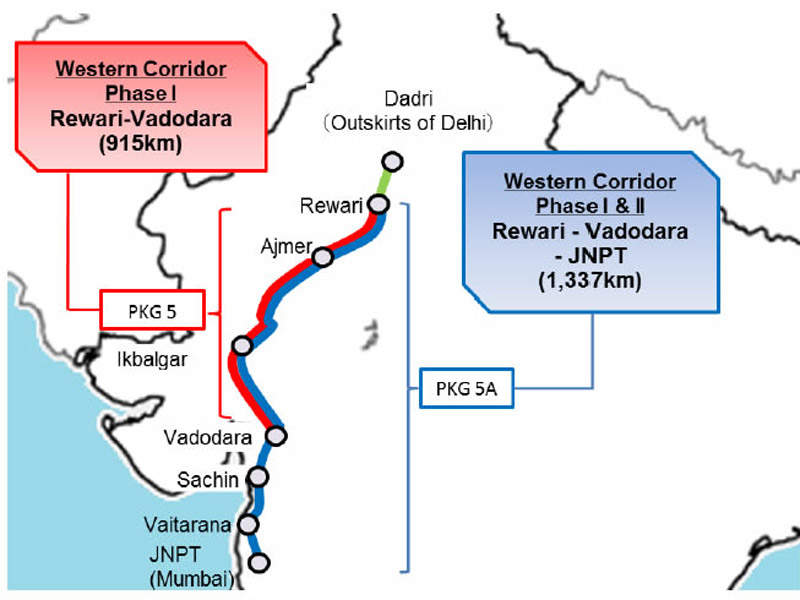

The Western dedicated freight corridor will cover a distance of 1,483km (928mi) of double-lane electric track from JNPT to Dadri passing through Vadodara, Ahmedabad, Palanpur, Phulera and Rewari. It will run parallel to existing line through Narnaul and Ringas.

The important stations that will come across the corridor will be Phulera and Marwar Junction in Rajasthan, Palanpur, Amli Road, Makarpura, Gothangam / Kosad in Gujarat and Vasai Road in Maharashtra.

A trial run on the 192km-long Ateli (Haryana)-Phulera (Rajasthan) section was conducted in August 2018. It was followed by another trial run on the 306km-long route between Rewari and Madar in December 2018. The Rewari-Madar section, which was completed under the first phase of the DFC project, will support heavy haul train operation with a 25t axle load.

Infrastructure and construction

The Western DFC will have special head-hardened (HH) 250m-long rails welded using Flash Butt welding machines. The axle load of the track will be 32.5t compared to the existing 25t axle load used on Indian rail tracks.

Construction on a 320km stretch of the project began in January 2016. It will be completed in two phases, with the first phase constructing a 186km-long segment, and the second building a 134km-long stretch between Sachin and Vadodara. The construction is expected to be completed by December 2021.

A 626km, double-track corridor has been built between Rewari in Haryana and Iqbalgarh in Gujarat, via Rajasthan, spanning three states. It included construction of 1,388km of total track length, including 1,342 bridges and 20 junction and crossing stations, and 68,000m² of building works.

Automated track-laying machines are being used to assist the construction. The project is also creating support infrastructure, including eight casting yards for bridge precast works, two sleeper plants for sleeper production, two rail welding depots, and two rebar yards for rebar works.

Further, 18 batching plants for producing concrete, 18 sand sources to cater to sand requirement and 11 Quarry sources to cater to concrete aggregate and ballast requirement will be built.

Rolling stock

The trains running on the Western DFC will be 7.1m-high, 3,660mm-wide, and between 700m and 1,500m-long. They will have a carrying capacity of 15,000t each.

Signalling and communications

The Western DFC will have an automatic train control system based on the European Train Control System (ETCS) standard to avoid collisions. The signalling and telecommunications equipment will include a train monitoring and diagnostic system to provide centralised monitoring of each train’s position on the track.

Electronic interlocking equipment will be installed to control signal lights and points, which will ensure the safe operation of trains. Level crossing warning systems will be activated automatically when a train is approaching. All applications will be linked through telecommunication systems.

Financing for Western dedicated freight corridor project

The project is funded by a soft loan of $4bn provided by Japan International Cooperation Agency under special terms for economic partnership (STEP). The remaining funds have been provided through equity by the Ministry of Railways.

Contractors involved with the Western DFC project

In May 2013, a consortium of Larsen & Toubro and Japanese firm Sojitz was awarded a INR67bn ($100.97m) contract to design and construct the 640km twin-track line of the western DFC.

The consortium was awarded a ¥50bn ($450,000) contract to supply and install 25kV, 50Hz electrification equipment on the 915km Rewari-Vadodara section of the Western DFC in November 2014.

The work includes construction of seven traction substations (TSS), one of which is GIS-based, 40 switching stations, and 897 track km of overhead equipment (OHE). It also includes SCADA works at 12 stations and an operational control centre, along with the supply of all associated equipment.

The corridor will be installed with traction power and auto transformers, as well as copper conductors imported from Japan.

In August 2015, Express Freight Consortium consisting of Mitsui, IRCON International and Tata Projects won a contract for track-laying and civil engineering work on two sectors between Vaitarana in the State of Maharashtra and Vadodara in the State of Gujarat.

The consortium led by Hitachi and consisting of Mitsui and Hitachi India won a contract worth ¥28bn ($27.13m) for the supply and installation of signalling and telecommunications systems for Package 5 of the Western DFC in December 2015.

Hitachi is providing key equipment for the signalling system, while Mitsui is responsible for co-ordination with DFCCIL and related agencies in Japan and India.

The consortium was also awarded a contract worth ¥11bn (approximately $9.19m) to supply and install an automatic train control system for Package 5A of the Western DFC in December 2015.