The X-Wagen is the latest generation of metro trains developed by Siemens Mobility, a global provider of mobility services, to operate on Wiener Linien’s U-Bahn railway network in Vienna, Austria.

Siemens was contracted to manufacture 34 X-cars for Wiener Linien, a public transportation operator, in 2017. The contract is aimed at modernising Wiener Linien’s fleet and replacing the Silver Arrow trains. It also includes 24-year maintenance of the trains and the option for an additional 11 cars.

The design for the new X-cars was showcased in March 2018 and the first test run took place in April 2021. The first X-Wagen metro train was delivered in July 2021 and underwent a series of tests before commencing operations at Erdberg station on the U3 line in June 2023.

The X-Wagen trains will allow Wiener Linien to provide a fully automated metro service on the U5 line in Vienna by 2026. Siemens is scheduled to deliver all the trains by 2030.

Siemens’ X-Wagen metro train design and features

The X-Wagen metro train is a super lightweight vehicle made of aluminium. The lightweight construction helps to significantly reduce the overall weight of the vehicle.

The six-car train is 111m long and 2.85m wide and can travel at a maximum speed of 80km/h. The maximum axle load is 10.9 tonnes and the train operates on a 750V DC power supply.

The vehicles are suitable for both automated and driver operations. They will operate in the automated configuration on the U5 line and driver mode on the U1 to U4 lines.

The train has a capacity of four passengers per square metre, for a total capacity of 928 passengers. The removable driver’s cab enables the cab space to be used for passengers in fully automated operations, thus increasing the train’s capacity by 24 passengers.

The trains offer step-free entries and exits and feature video monitoring with live streaming to the control centre, which enhances passenger safety.

Interior design

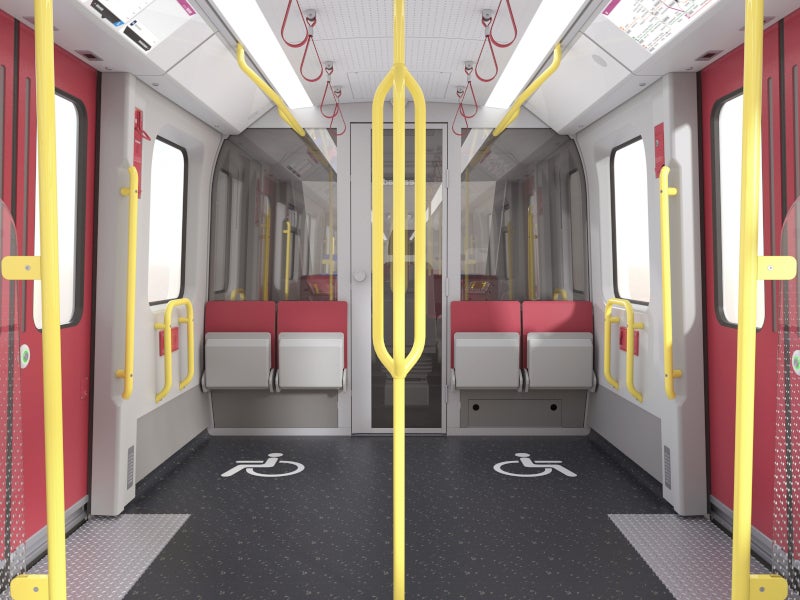

The X-Wagen metro vehicle has an open-concept airy interior with large entry spaces that make it easier to get in and out of the vehicle. The trains are air-conditioned and have ample space available for passengers travelling in buggies or with luggage.

Each train consists of 200 seats made from durable plywood. The seats are configured as a combination of conventional transverse seats with longitudinal and folding seats.

The blue-coloured seats are designated as priority seats and are reserved for people with restricted mobility. Three doors are provided on each car side of the metro vehicle.

In addition, six wheelchair spaces are available, two of which are in the middle of the train.

Passenger information system

The digital passenger information and control system shows door-selective up-to-date real-time information to the passengers on the screens mounted above all the entrances inside the X-Wagen metro.

The screens display directions to the station’s exits, other transfer lines, and departure times for the lines thereby improving passenger flow. They also display the digital network map showing the train’s current position, the train’s journey direction, the next station, and relevant transfer options.

Additional information such as scheduled metro closures or station elevators that are out of service can also be displayed.

Braking system details

The X-Wagen vehicle uses an airless braking system that works by sending a purely electronic signal through a brake control unit and the brake calliper, which is an intelligent actuator. The actuator provides high-quality braking, particularly in low-grade rail systems.

The airless system eliminates the usual compressed air components underneath the carriage, reduces the weight and installation space, and minimises the time taken for a vehicle to be ready for operation throughout its life cycle.

Sustainable features

The X-Wagen metro trains are made with 90% recycled materials and require low maintenance.

The trains are energy-efficient because of their design and equipment installed such as LED lights used for both the interiors and exteriors.

Contractors involved

Liebherr, a systems and parts supplier for the railway sector, supplied air-conditioning systems for the X-Wagen metro trains.

Ewald Neuhofer, an interdisciplinary industrial design business, provided the interior and exterior design for the new trains.

HÜBNER, a mobility and industrial products provider, supplied gangway systems for the trains.