Hyperloop Transportation Technologies (HTT) is developing a new hyperloop system, which is designed to offer emission and noise-free operation at a maximum speed of 1,223km/h.

The company unveiled its full-scale passenger hyperloop capsule called Quintero One for the first time in Puerto de Santa Maria, Spain, in October 2018, coinciding with the company’s fifth anniversary.

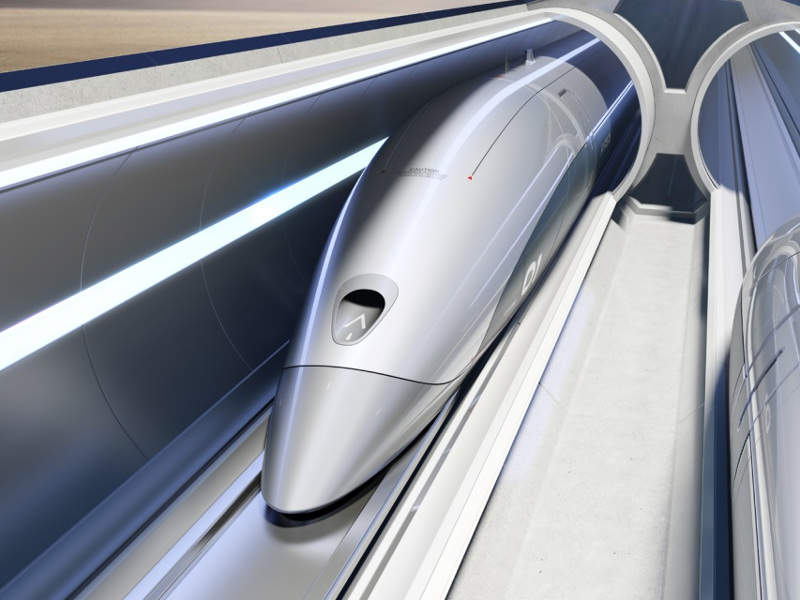

The Quintero One capsule is designed to offer a next-level rapid transportation solution by safely moving people and goods at unprecedented speeds. It forms a major component of the HTT hyperloop system, which also includes large low-pressure vacuum tubes based on pylons, and stations.

HTT hyperloop system development details

Incorporated in November 2013, HTT completed the feasibility study on a new hyperloop system in December 2013. The company filed for permits to start the construction of the system in February 2015.

The Slovakian government signed an agreement with HTT for the development of a local hyperloop system in March 2016. HTT licensed the passive magnetic levitation system from Lawrence Livemore National Labs (LLNL) for its hyperloop application in May 2016.

Vibranium, a smart material created for the hyperloop system, was unveiled by HTT during the Pioneer’s Festival in May 2016. Construction of the first full-scale hyperloop capsule began in January 2017.

HTT also signed partnership and development agreements with Abu Dhabi, the city of Toulouse, Czech Republic, Indonesia, Republic of Korea, India and Ukraine for the hyperloop system.

HTT hyperloop system technology

HTT’s hyperloop system utilises passive magnetic levitation (MagLev) electromagnetic propulsion, a linear induction motor, and embedded rechargeable batteries to power the capsule.

The magnets are arranged in a Halbach array configuration to allow for passive levitation of the capsule over a conductive track called Inductrack.

The tubes will be primarily based on concrete pylons and will have a low-pressure environment created by vacuum pumps jointly developed by HTT and Leybold. The vacuum pumps will also significantly reduce the drag forces.

Quintero One capsule design and materials used

The Quintero One is made of Vibranium, which is a smart material developed by HTT. Integrated with embedded sensors and carbon-fibre compounds, the material provides the required structural and sensory attributes to the capsule.

Vibranium is ten times stronger than steel and eight times stronger than aluminium. It weighs five times less than steel and 1.5 times lesser than aluminium, and highly augments the capsule efficiency.

The pressurised capsule is equipped with customised interiors and augmented windows. It has a length of 32m, diameter of 2.7m, and weight of 5t and can house up to 40 passengers. It features seats, a luggage compartment, and entertainment displays. Each passenger will be provided with a personal entertainment system.

The capsule’s smooth, silent and emission-free thrust is ensured by linear induction motors, rechargeable batteries, and electromagnetic propulsion. The batteries deliver high energy output and a small thermal footprint.

Hyperloop system infrastructure

HTT plans to develop associated infrastructure to ensure minimal interference with road traffic. It primarily focuses on lower land acquisition costs, stability, and structural integrity in the event of an earthquake to develop infrastructure for the system.

The elevated reinforced concrete pylons and beams above the ground will reduce the investment in land acquisition. The tubes can also be laid at ground level and underground according to the requirements of the project and the terrain variances.

Stations and control centres

HTT in collaboration with AN.ONYMOUS created an innovative design for an energy-efficient, next-generation station with effective utilisation of space. The station will have the capacity to accommodate 3,600 passengers an hour.

The fully-automated hyperloop system will only need to be monitored by humans and operational control centres will provide real-time assistance and response to make transport safe and reliable.