As the UK continues its slow efforts to decarbonise its railways, moving from diesel-powered rolling stock to electric is vital.

While battery-powered trains will be an essential choice in some areas, in the main the most effective method of decarbonisation is to electrify the railway. Electric trains are cheaper to manufacture, and thus on average 20% cheaper to lease as well as 33% cheaper to maintain.

The cost of powering the train is typically 45% lower because electric trains are lighter and more efficient, and electricity from the National Grid is cheaper than diesel fuel, as electric trains are lighter they cause on average 13% less wear to the tracks.

Environmentally, electric trains do not pollute the air during operation. According to Network Rail, they emit 20-30% less carbon per passenger mile than diesel-powered locomotives.

Electrification plays a crucial role in modern railway systems, providing efficient and sustainable power to trains. The two most common methods of electrification are overhead lines and third rail electrification.

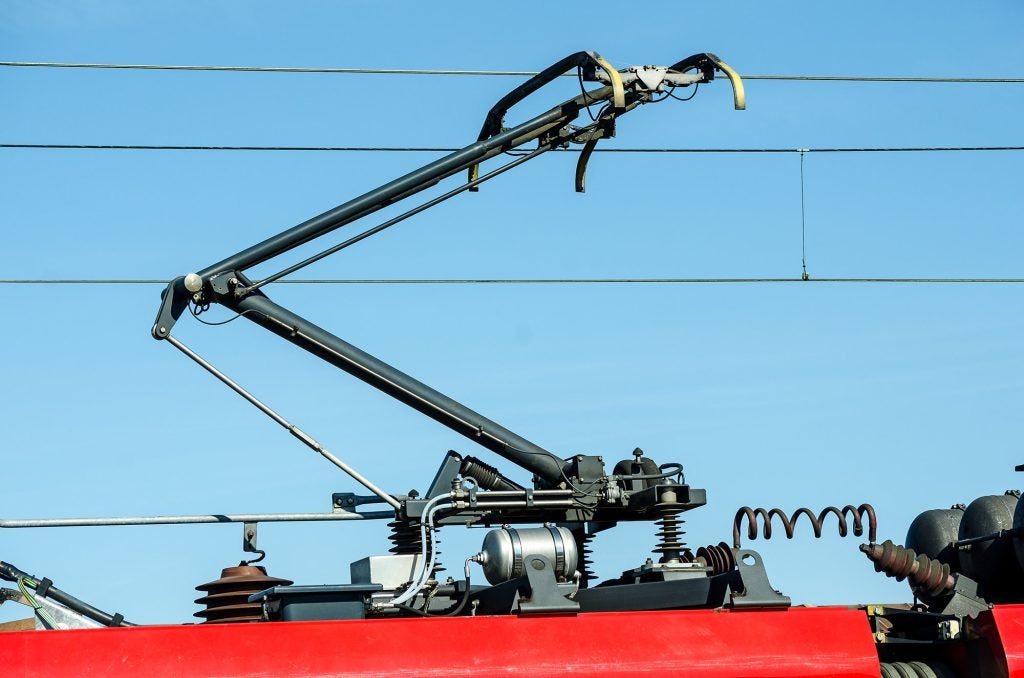

Electrification through overhead lines

Overhead lines, also known as overhead catenary systems, utilise a network of wires suspended above the tracks to supply electric power to trains. The system operates on alternating current (AC) and is widely used in mainline and high-speed railway networks.

How well do you really know your competitors?

Access the most comprehensive Company Profiles on the market, powered by GlobalData. Save hours of research. Gain competitive edge.

Thank you!

Your download email will arrive shortly

Not ready to buy yet? Download a free sample

We are confident about the unique quality of our Company Profiles. However, we want you to make the most beneficial decision for your business, so we offer a free sample that you can download by submitting the below form

By GlobalDataOne of the primary advantages of overhead line electrification is its ability to carry high-voltage power, typically 25,000 volts AC. This higher voltage allows for efficient power transmission over long distances, reducing energy losses and enabling power supply substations to be spaced further apart.

As a result, overhead lines are very suitable for railways with widely dispersed power sources.

Another advantage of overhead lines is their compatibility with longer and heavier trains. The high-voltage power supply eliminates the need for onboard transformers, reducing the weight and cost of rolling stock. In turn, this can increase the capacity of trains and allow for higher passenger numbers and improved operational efficiency.

Despite its advantages, overhead lines also have some drawbacks. One significant disadvantage is the visual impact of the wires and support structures on the surrounding landscape. Overhead lines can be considered unsightly, especially in scenic areas or urban environments with strict aesthetic requirements.

Another challenge is the need for extensive infrastructure modifications. Bridges, tunnels, and other structures along the railway route must be adjusted to provide sufficient clearance for the overhead wires. This can be costly and time-consuming, especially in densely populated areas.

Further, overhead lines are more susceptible to weather-related disruptions. Strong winds, heavy snowfall, and ice accumulation can cause wires to sag or break, leading to service disruptions and maintenance requirements. Therefore regular inspection and maintenance are necessary to ensure the system is reliable.

Third Rail Electrification

The third rail electrification system, also known as the contact rail system, provides power to trains through a conductor rail placed alongside, or between, running rails. Trains have metal contact blocks, or ‘contact shoes’, which make contact with the conductor rail. Conductor rails are mostly steel (a specially conductive type).

This system primarily operates on direct current (DC) and is commonly used in metro and urban transit systems. More than 30% of the UK rail network currently uses a third rail to power the train, commonly in the southeast and in dense urban areas around the country.

One of the significant advantages of third rail electrification is its cost-effectiveness. Compared to overhead lines, the installation and maintenance of the third rail system require fewer infrastructure modifications and are generally more affordable. This makes it an attractive option for urban transit systems with shorter distances between power supply substations.

Third rail systems are also less vulnerable to weather-related disruptions that affect overhead wires. As the third rail is on the ground it is unaffected by strong winds and less exposed to heavy snowfall. This reduces the likelihood of service interruptions due to weather conditions – but that’s not to say a third rail system is fully immune to them.

While third rail electrification has its advantages, it also presents several challenges. While less affected by snow or high winds, flooding can pose problems on railways using third rail electrification. The lasting damage that flood water can cause to infrastructure can lead to ongoing repair work that takes days, weeks or even months.

One of the primary concerns is safety. The third rail carries a high voltage, typically around 750 volts DC, which poses a significant risk to individuals who come into contact with it. Adequate safety measures must be in place to prevent unauthorized access to the tracks.

Third rail systems are also limited in terms of speed capabilities. Due to the mechanical impact on the contact shoe and the gaps in the conductor rail at level crossings, crossovers (a pair of switches that connects two parallel rail tracks), and substation gaps, the top speed of trains is often restricted. This makes the third rail system less suitable for high-speed railway applications.

Additionally, the third rail system may not be as efficient for longer or heavier trains. The weight and cost of transformers required onboard the rolling stock can limit the capacity and operational efficiency of the trains. This leads to the most common use cases of a third rail system being in metro and urban transit systems, with shorter distances between stations.

Which electrification system is better?

While both systems have their pros and cons, there is no ‘better’ choice. The method of electrification depends entirely on the context of where it is being used.

The type of railway, its location, operational requirements, and cost implications all play a role in determining the most suitable method of electrification.

For mainline and high-speed railways with long distances between power supply substations, overhead line electrification is often the preferred choice. The ability to transmit high-voltage power efficiently and support longer trains makes it a suitable option for these applications.

In contrast, metro and urban transit systems with frequent stops and shorter distances between stations often benefit more from third-rail electrification, as the cost-effectiveness and lower susceptibility to weather-related disruptions make it an attractive option.

It is important to note that each electrification system has its own safety considerations. Arguably, a third rail is the more dangerous, as trespassers on the tracks are in more danger of making contact with the third rail compared to an overhead line.

With that said, proper training, safety protocols, and physical barriers must be in place to ensure the safety of railway staff and the general public when using either electrification method.

Ultimately, the decision will be based on a thorough analysis of the specific requirements and constraints of the network in question.

This article was originally published in our digital magazine, Future Rail. You can subscribe for free here.