Sulzer supplies customised service solutions to optimise the performance and reliability of traction motors and other rotating equipment.

The company also performs automatic undercutting, profiling, welding and resurfacing of commutators, as well as rotor testing and in-situ commutator profiling.

Repair, overhaul and re-engineering of railway components

Sulzer is experienced in servicing AC and DC traction motors, generators, bogies, braking systems, gearboxes and equipment used in the transportation sector.

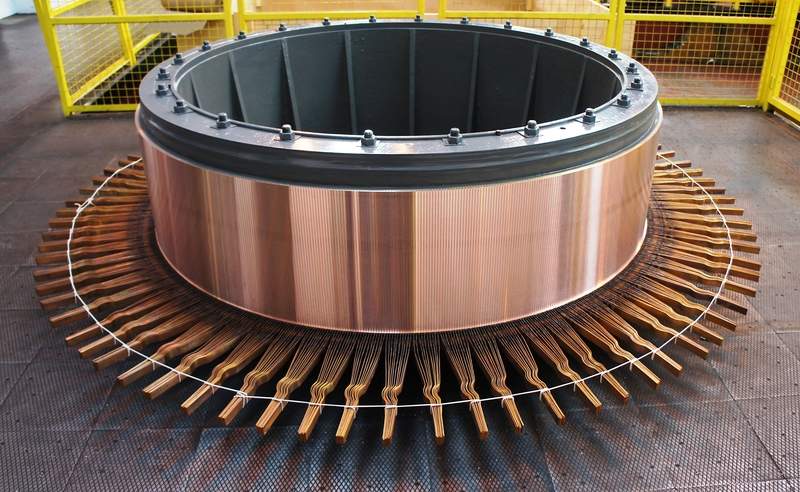

With extensive design and manufacture capabilities, the company produces commutators and slip rings, in addition to complete motor and generator repairs.

Sulzer’s workshops are equipped with the latest 3D computer-aided design (CAD) systems and software for re-engineering and manufacturing of both mechanical and electrical components.

Rail inspection and testing services

Sulzer’s service capabilities range from inspection to repairs, testing, and commissioning. The company’s overhaul processes extend the lifetime of all critical parts and its highly effective processes offer fast delivery.

All services comply with Railway Group standards and approved procedures.

Locomotive bogie maintenance

Sulzer supplies a wide range of services to maintain locomotive bogies.

The company measures, develops and installs suspension pads, as well as replaces primary and / or secondary pads.

Sulzer also performs symmetry measurement inspection, in-situ machining on the bogie, and removal of broken studs and line boring.

Traction machine services for the rail sector

Sulzer offers industrial services for traction machines and motors, including welding repairs, non-destructive testing, removing damaged sections, precision measuring and hot wire tungsten inert gas (TIG) welding.

Additional traction services include:

- Commutator machining, undercutting and beveling

- Low and high-speed balancing

- TIG and metal inert gas (MIG) welding

- (Dielectric) in-house or on-site testing

- Load and black band testing

All services are performed in-house, which improves the workflow and the efficiency of the project, as well as the cost-effectiveness for clients.

About Sulzer

Sulzer makes sure clients receive the highest quality repair and fastest delivery by managing each stage of the project, from design to testing and re-installing serviced parts.

The company provides localised services in approximately 100 locations, optimising the project experience and enabling clients to maintain and build on the relationship with their local repair centre.