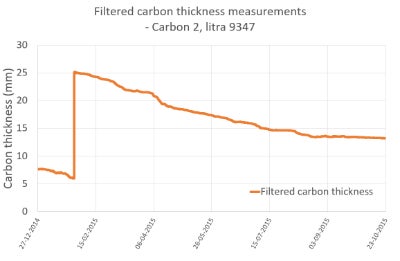

PantoInspect is excited to announce a great accuracy improvement for carbon thickness measurements. We obtained improved accuracy by applying statistical analysis to recent train passages, which is possible in the new 2.0 version of the software where historical data is much more accessible.

For one of our main customers, the new method resulted in an improvement in thickness measurement accuracy from about +/-1.9mm to about +/-0.1mm. This extreme level of accuracy allowed us to predict each millimetre of wear with an uncertainty of about 90 minutes. This means that with for example 4mm of carbon left above threshold, we can predict the exact day when an alarm will occur and even present a decent guess of the hour the event will happen. All this is of course from data obtained from an actual system running in production with trains passing at full speed.

The direct benefit of improved carbon thickness is fewer false alarms, but sub-millimetre accuracy also opens new possibilities for pantograph maintenance. Not only will it be possible to schedule maintenance dynamically as needed, but it will also be possible to make early detection of unusual wear.

Predictive pantograph maintenance is a field that will gain high priority in PantoInspect and we expect to be able to offer rolling stock maintenance reports to operators later this year with unprecedented accuracy.

For further information, please contact PantoInspect.