SICK’s smart light grids (SLG) are monitoring systems for a range of rail applications.

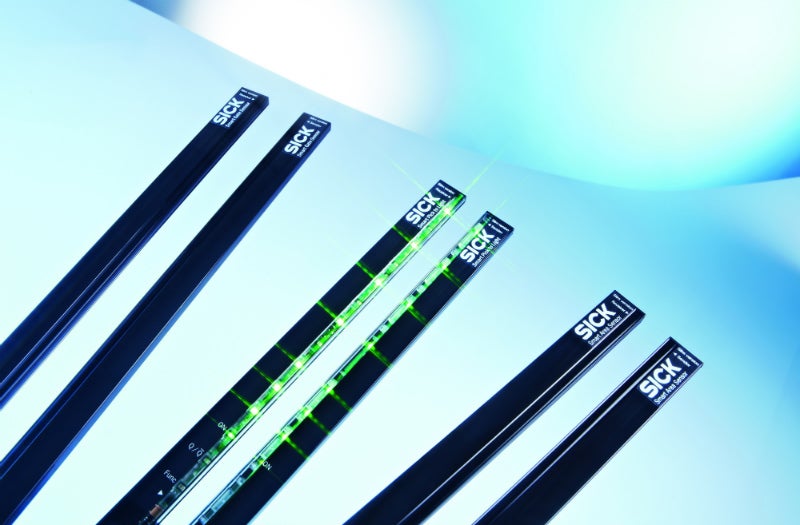

SLG systems are 8mm deep, 25mm wide, and offer a variety of lengths. Featuring an optical light exit, they are suitable for virtually all situations and can be integrated into walls, doors, conveyor belts, machines or shelves for industrial gates, as well as stocking small parts.

The SLG product family consists of the smart area sensor (SAS), smart gate sensor (SGS) and smart pick-to-light light grid (SPL) automation light grids.

SICK’s SGS light grids feature a range of 10m and detection heights up to 1.4m, meaning they can be used in wide applications, such as entrance and exit monitoring for vehicles at industrial sites. Their particularly narrow design enables them to be installed virtually invisibly for use as an innovative monitoring system at turnstiles in airports and train stations. Here, SGS light grids will ensure turnstiles do not close after the person has exited if objects are still located within the turnstile.

SAS light grids are the perfect solution for numerous industrial automation tasks for and in machines. Their small size enables them to be used in virtually all situations, such as checking overhang in the electronics industry.

The SPL light grid provides visible indicator and job LEDs across its entire detection height, enabling effective support for picking in small parts racks. A window allows workers to immediately detect current removal compartments at a glance. A further benefit of the SPL is its integrated monitoring system for incorrect removals; as soon as a part is removed from a compartment which has not been indicated, the job LED will light up red. The SPL therefore makes a valuable contribution to quality assurance.