LINSINGER provides rail milling machines for quick reprofiling of railheads for minimal traffic disruption.

Our mobile rail milling machines are used for mainline, suburban and metro railway lines, as well as rails, switches, crossings and tunnels. They are suitable for regular maintenance of rail profiles and designed to minimise process and operational malfunctions.

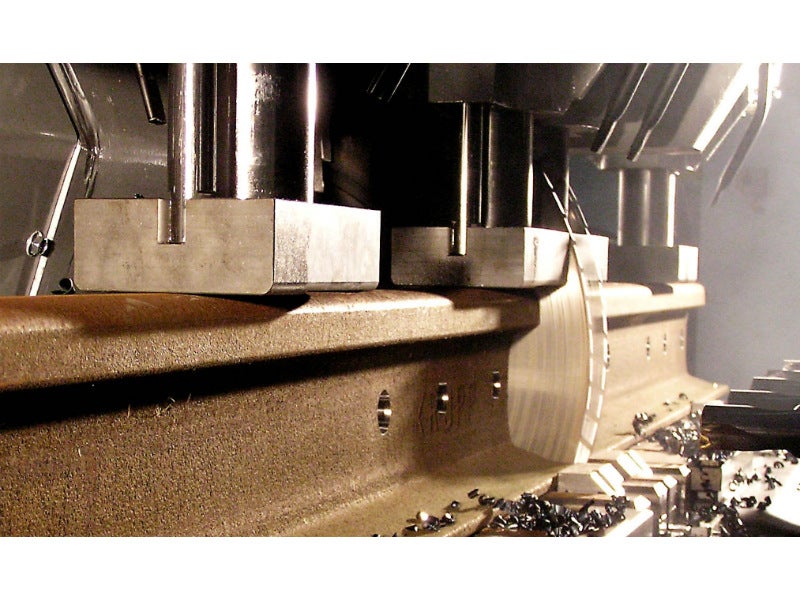

Rail milling machines for railhead profiling

Rail profiles require regular maintenance due to the constant wear they encounter during everyday operations. This helps to enhance railway traffic safety and service life, as well as lower operating costs.

Our machines are suitable for mainline tracks and switches to provide a decarbonised layer on the line, as well as noise reduction or gauge correction. They can be used for preventative or corrective maintenance and improvement of railhead failures in transverse or longitudinal profiles.

Milling machines can be used to modify or completely change rail profiles, as well as improve the running behaviour and wear reduction.

Railhead reprofiling for enhanced railway operations

LINSINGER rail milling machines finish processing in one traversing step and are capable of removing individual materials from 0.1mm to 5mm. It is an environmentally friendly procedure that does not produce chip or grinding dust pollutants with no fire risk from flying sparks.

The machines can be used in sensitive areas without the need to remove track switching equipment. They have high processing precision and are gentle on materials.

Profiling machines for new and used railway track

LINSINGER provides railhead reprofiling of new and used railway track in single-pass processing. This is carried out using our advanced milling and grinding technology.

We have a wide product range that features rail milling machines for high-speed, city and tram railways, as well as switches, crossings and turnouts.

Railway trucks can be provided for adaptable operation, as well as stationary railhead milling machines for welding and repair centres.

About Linsinger Maschinenbau

LINSINGER has more than 60 years of experience in milling technology for a range of sectors. Our technology has been used in railway track maintenance for 20 years, with over 50 of our rail milling vehicles being used across the world.

Based in Austria, we manufacture and supply milling and grinding technology with a range of machinery and processing vehicles available in our product range.

For more information about our rail milling vehicles and machines, fill out the enquiry form on this page and we will be in touch.