Iron ore railways in the Pilbara region of north-west Western Australia are the most productive railways in the world and are set to improve over the next few years now that Hamersley Iron has finalised an agreement with Robe River Iron Associates to form a joint rail operation.

Hamersley Iron and Robe River Iron’s railway operations were combined in 2002 to form Pilbara Rail, the company which is now in control of both rail networks as a single operation. Both the original companies still retain ownership of their own locomotives, track and rolling stock. Pilbara Rail’s main focus is to maintain the system and ensure that deliveries of iron ore are made from the mines to the ports.

Today the Pilbara Rail operation consists of more than 1,100km (687.5 miles) of railway, which is used to move around 110 million tonnes of ore every year across the stark landscape of Western Australia. Pilbara Rail is the largest privately owned and operated rail network in Australia.

The project

The iron ore railway network of Pilbara Rail undergoes development as mines are expanded. It is usually an increase in production that requires a change in the railway operation.

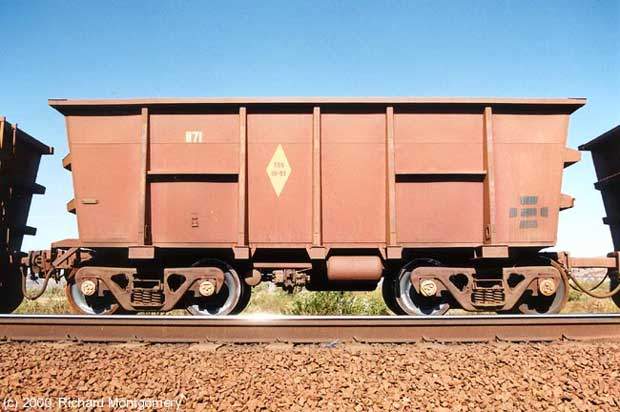

The main part of the system between the port at Dampier and the Tom Price mine was built in 1966, with additional spur lines developed to Paraburdoo, Marandoo, Brockman and Yandicoogina mines. Trains of up to 226 wagons each loaded with up to 105 tonnes of iron ore are moved around the system using head-end (locomotives at the front of the train) power only, making the system unique in the world for the weight of the train.

The opening of Yandicoogina Mine in 1998 required a complete new 147km line to be built from the main Dampier-Tom Price route. A 180,000-tonne stockpile has been built at Yandicoogina which is removed in trainloads of 23,500 tonnes. The journey to Dampier takes around nine hours.

In 2004 a doubling scheme was started by Pilbara Rail to provide extra capacity on 95km between Tunkawanna and Rosella Sidings on the main Tom Price-Dampier route.

Infrastructure

The second track runs parallel to the current mainline, on an embankment for most of its length and within 100m of the original 1966 Hamersley route. It features concrete sleepers and 68kg deep hardened rail, and some 190,000m of continuously welded rail and 140,000m³ of ballast will be needed. Connections will be made to five sidings on the original route. The project, to be completed by the end of 2006, requires two major and five minor bridges.

Rolling stock

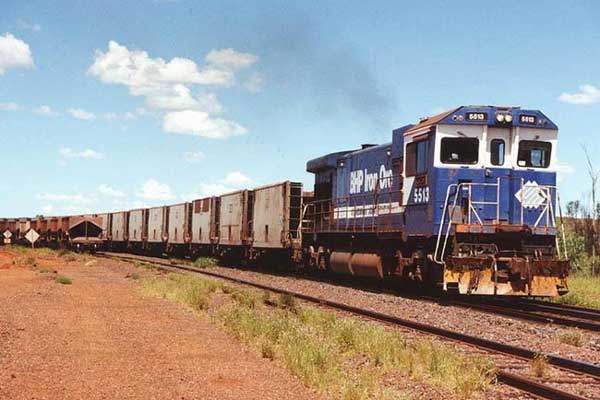

Twenty-nine General Motors Dash 9 locomotives form the main thrust of the locomotive fleet, normally in sets of three to handle the massive 2.2km-long iron ore trains. Lower-powered Dash 7 and Dash 8 locomotives are mainly used around 7 Mile Yard to shunt wagons for unloading.

A fleet of 2,400 wagons are formed into sets of 226.

A demonstration of the system’s capabilities was the breaking of the record for the heaviest train by BHP Iron Ore. One weighing 99,734 tonnes ran for 275km between Yandi and Port Hedland on BHP’s Mount Newman line. It was formed of 682 wagons hauled by eight 6,000hp General Electric AC6000CW locomotives and controlled by a single driver. The 7.3km long train conveyed 82,000 tonnes of iron ore.

Signalling and communications

Trackside signals are now extinct on the Pilbara Rail system of Hamersley and Robe River Railway’s following their replacement with in-cab signalling. It relays the limit of the driver’s authority using a display in the cab.

Control is handled by three train centres, which will be increased to four following completion of the track doubling scheme. The headquarters is at 7 Mile Yard.

The future

The output of Yandicoogina mine is to be trebled to 36 million tonnes of iron ore per year, which will increase the stockpile in the rail loop at Yandicoogina to 600,000 tons.