C.A.T.E.R (Centre for Advanced Transport Engineering and Research) develops innovative and cost-effective rail inspection systems offering ease of data collection and comprehensive analysis through reliable and proven engineering.

C.A.T.E.R provides quality engineering in the rail industry focused on predictive maintenance, condition monitoring, flaw trending, and an extensive array of rail specific instrumentation.

HANDWave Series II portable RFD tester

HANDWave, a portable RFD testing system, is a powerful and economical alternative to RFD vehicles as it has virtually identical detection performance to larger RFD vehicles.

The 2013 Series II release comes from understanding and addressing those customers’ needs with this unique solution. The essential element to maintain is the unique concept of having one modular unit to be able to test one rail (SRT-Single Rail Tester), two rails at a time (DRT- Dual Rail Tester) or in an automated way by the DRT being towed by a small rail vehicle.

The advantage of this flexibility of setup offers significant cost savings for operators as this removes the need for the purchase, staffing and maintenance of several different types of vehicles.

HANDWave is a robust and lightweight ultrasonic rail flaw detection tool with powerful detection, display and processing features for flaw verification of main track, sidings, depots and yards in one continuous test of the rail.

ULTRAWave ultrasonic rail flaw detection system

ULTRAWave is an ultrasonic rail flaw detection (RFD) system that reduces the cost and risk of testing for rail network operators. C.A.T.E.R has refined decades of experience in supplying train borne RFD systems to offer the most comprehensive ultrasonic rail inspection system including the portable level of HANDWave.

Rail networks can tailor the system to specific requirements, a feature that was previously unavailable to rail operators. Networks can select from a range of carriers and ancillary functions to provide a cost-effective maintenance regime for a particular situation.

A major advantage of the ULTRAWave RFD system is the common software and interface across all levels of C.A.T.E.R ultrasonic systems. For example, HANDWave uses ULTRAWave LITE, a portable version of the vehicle-based systems. The same test operator is able to work at the pedestrian level of HANDWave up to the full train-borne systems with several rail inspection systems onboard. This commonality offers savings in staffing and training costs by the use of the same operator pool when a range of vehicle-based or portable RFD systems are employed.

Features of ULTRAWave include the accurate identification of rail foot corrosion, all software is PC-based for lower cost and shorter down-time and the accurate location tagging of artefacts.

VIDWave rail imaging with video identification system

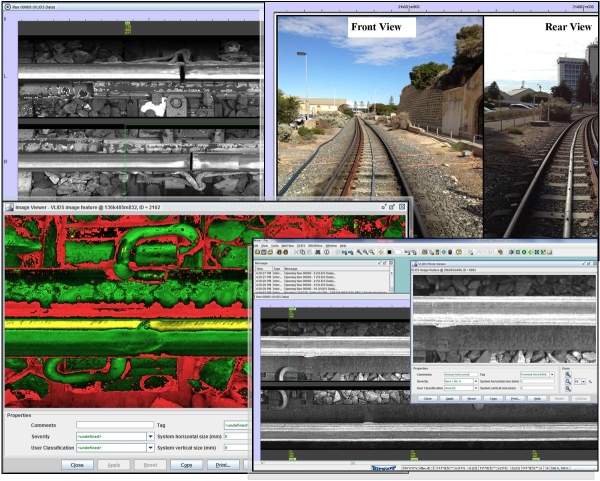

C.A.T.E.R’s Video IDentification System (VIDWave) is primarily used to inspect and visually confirm other rail inspection information. However, VIDWave can also be employed as a stand-alone (independent) system. VIDWave uses continuous high-speed imaging to aid the assessment and verification of potential flaws in the rail environment in real-time and during post-processing.

Synchronization with the ultrasonic information in post-processing improves the accuracy of rail flaw assessment and reduces analysis and maintenance time by accurate identification of rail issues. Images to identify and verify location can be viewed immediately in real time or during post-processing.

VIDWave can provide not only accurate inspection of the rail surface but also tie (sleeper) condition, ballast, PerWay assets, absence of clips and debris on or near the rail.

RIPWave rail condition monitoring system

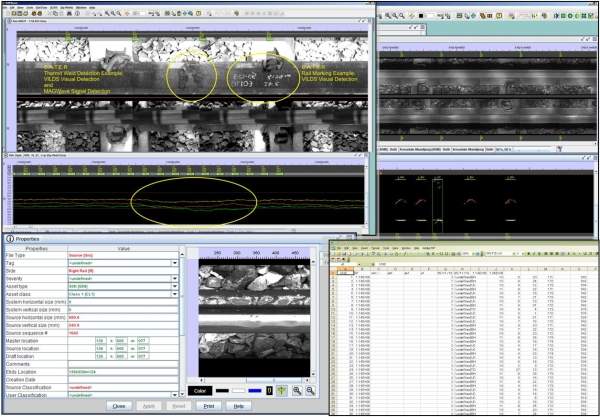

C.A.T.E.R’s Rail Intelligent Permanent Way Analysis ViEwer (RIPWave) is a powerful post-test analysis tool for genuine condition monitoring solutions and flaw trending. The software identifies, classifies and verifies potential problems associated with the rail environment.

RIPWave’s ability to support extensive analysis and reporting capability, including run-on-run comparisons, is demonstrated by its capacity to collate, synchronize, filter and report on all RFD/UT, visual information, Track Geometry, Rail Profile Measurement, Corrugation and other related rail related information.

The C.A.T.E.R. aim is to provide the opportunity for rail networks to trend rail condition and develop a predictive regime of maintenance from the extensive tailored (network specific) information collected.

Customer focus for more effective RFD systems

C.A.T.E.R embraces developing better systems in response to customers’ needs. The company is focused on expanding its markets internationally with tailored solutions for effective Rail Inspection systems.