KONI is a leading manufacturer of hydraulic dampers for rail rolling stock and automotive applications. Its position as a world–leading damper company is ensured not only by a high degree of engineering advancement, but also a long, successful history as a trusted partner and specialist in noise and vibration control products.

Our R&D department is totally committed to offering the best damper solutions for each unique rail transportation system. To best serve the railway market, we have developed three damper product lines, each with unique benefits.

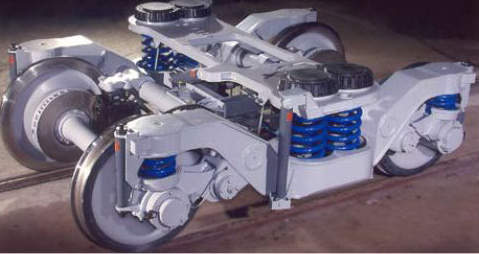

Dampers for primary–vertical, secondary–vertical and secondary–horizontal bogies

Our Performance Line dampers offer excellent value for money and are among the latest damper innovations for primary–vertical, secondary–vertical and secondary–horizontal bogies.

These high–quality products provide a maintenance–free superb operation until the next planned major overhaul of the bogies. The product can subsequently be replaced by a new damper or overhauled in a specialized workshop.

The production line for these dampers makes use of the latest production technologies, which results in a high level of automation and the elimination of unnecessary handling. These dampers are optimized to achieve the lowest possible initial purchase price without compromising the quality of the product.

The dampers include the following features:

- Robust construction, resulting in long service life

- Symmetrical force in extension and compression

- Linear force rate up to a freely defined blow–off point

- Maintainable or sealed construction at customer’s request

- The special synthetic rings around the piston and the guide, result in the absence of any metal–to–metal contact

- High–quality silent blocks

- Noise–free valve systems

Adaptable, long–lasting rail dampers

Our Endurance Line dampers are designed for at least 25 years of operation. These extremely robust products wear at a very slow rate and can easily be adjusted and reconditioned to new conditions.

The circulating–oil principle guarantees unmatched symmetrical damping forces and provides for an excellent heat transfer between the damper and surrounding air, allowing them to operate in the most extreme conditions. The design is optimized to achieve the highest possible dependability while allowing the longest time between consecutive overhauls.

Endurance Line dampers are available for the following applications:

- Primary–vertical bogies

- Secondary–horizontal bogies

- Secondary–vertical bogies

- Inter–car

- Yaw

- Anti–roll

Yaw dampers for small–amplitude sinusoidal bogies

Endurance Line yaw dampers are specially designed to control small–amplitude sinusoidal bogie rotational movements and thereby enable trains to be operated at speeds above those previously possible. The same technology is also used in our inter–car dampers.

This robust construction of the Endurance Line dampers is reflected in:

- Large diameter of the piston rod limiting the surface pressure due to side loads, providing reduced friction and a long lifetime

- High–quality silent blocks

- Low–friction multiple seal system

- The special synthetic rings around the piston and the guide result in the absence of any metal to metal contact

- Noise–free valve systems

- Screwed dust cover; no welding required

- Internal or external dust bellows, protecting the piston rod against small abrasive particles

High–capacity shock absorbers

With the newest innovations in energy absorption technology we offer the widest selection of high-capacity shock absorbers in the world. They are used as energy dissipation devices installed in automated couplers and draw bars to provide crash protection from frontal and rear impacts caused by vehicle–to–vehicle collisions.

High–capacity shock absorbers also form an essential component in fixed and sliding end–of–track–stops.

Vibration isolation products

Our vibration isolation products are custom-engineered to solve your complex shock, vibration and noise isolation problems. Our engineers utilize proprietary 6°–of–freedom analysis programs along with extensive dynamic testing capabilities to quickly transition from concept to production.

Pantograph dampers

Our Technology Line products include pantograph dampers and door–actuator dampers. The relatively small pantograph damper has a position-dependant performance characteristic. It is customized to control the pantograph in working position in contact to the catenary, as well as lowering the pantograph to the roof.

Train door–actuator dampers

Controlling the door movements in such a way that the doors close and open with exactly the correct speed and without slamming can be performed using dedicated stroke–dependent dampers.