JAQUET speed sensors are used in railway, metro and tram applications to: measure speed in the motive power system; control the brakes to prevent wheel locking and slippage; provide speed and direction information for train control; provide protection and data recording, and provide input data for engine diagnostic systems.

SENSORS FOR MOTIVE POWER

The motive power systems used in today’s trains are either based on diesel engines or electric supply. In every case, however, modern trains are finally driven by electric motors whose energy is controlled by a propulsion system. These motors are normally equipped with a pole wheel, which is sensed by a speed sensor. As the system needs to drive the train forwards and backwards, the sensor has two phase-shifted channels, thus enabling direction sensing.

CAM- AND CRACK-SHAFT SENSORS AND TURBO SPEED SENSORS FOR DIESEL ENGINES

Diesel engines require:

- Cam- and crack-shaft sensors for start and operational control

- Turbo speed sensors and associated converters

- Over-speed protection and performance monitoring

All of these applications are covered by JAQUET’s speed sensor, tachometer and IQ speed sensor solutions.

In addition, JAQUET provides cutting edge diagnostic solutions:

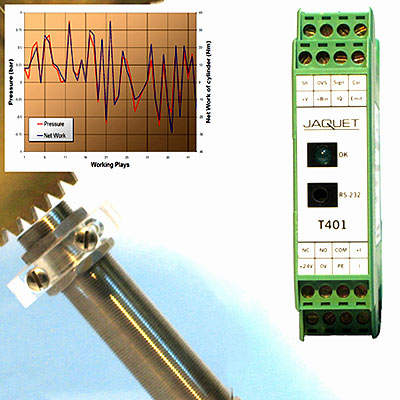

ENGINE DIAGNOSTICS USING CRANKSHAFT SENSORS

Diesel engines do not rotate uniformly. Using high performance speed and position sensors, JAQUET’s MDS4000 system analyses the finite rotation of the engine’s crankshaft and thereby reduces the work contribution made by each cylinder. This allows early detection of faults such as valve seating, injector failure and detonation.

Asset utilisation and maintenance scheduling is then brought under better control.

ABS BRAKE SENSORS AND WSP BRAKE CONTROL SYSTEMS

Brake control systems are variously described as ABS (Anti Lock Braking System) or WSP (Wheel Slip Prevention). Coupled with the traction control offered by sensing motor speed, these systems prevent wheel slippage and brake locking, thus reducing wheel and track maintenance, increasing reliability and enhancing safety.

Typically a single-channel hall effect sensor with a push-pull output stage is used to detect the speed of the spinning wheel. This speed needs to be monitored down to very low rpm as only then can an effective anti-locking mechanism be established.

Most important is the robust and strong construction of the sensor used in the harsh environment of a railway application at axle level. The fully encapsulated stainless steel housing and integral armoured cable allow direct use on motors, bogies or down at the axle.

Some applications require a second speed sensor channel for an additional function, e.g. a security installation which only allows the doors to be opened at standstill. Naturally the electrical wiring must then be isolated from the primary function. For this purpose, JAQUET supplies redundant double-headed sensors in the same housing.

SENSORS FOR RAILWAY SIGNALLING, CONTROL AND RECORDING

Speed and direction also form part of the input requirement for train control, protection, signalling and recording. These requirements are usually satisfied by either bogies or axle mounted, two-channel sensors.

The multitude of sensors required on trains often causes space problems. JAQUET offers a solution to this in the form of three or four channel sensors in one housing.

The innovation brought by JAQUET to the railway industry has been recognised worldwide. All our railway sensors are qualified to international standards for both bogie and axle level environments. Tomorrow’s solutions are always under development at JAQUET.