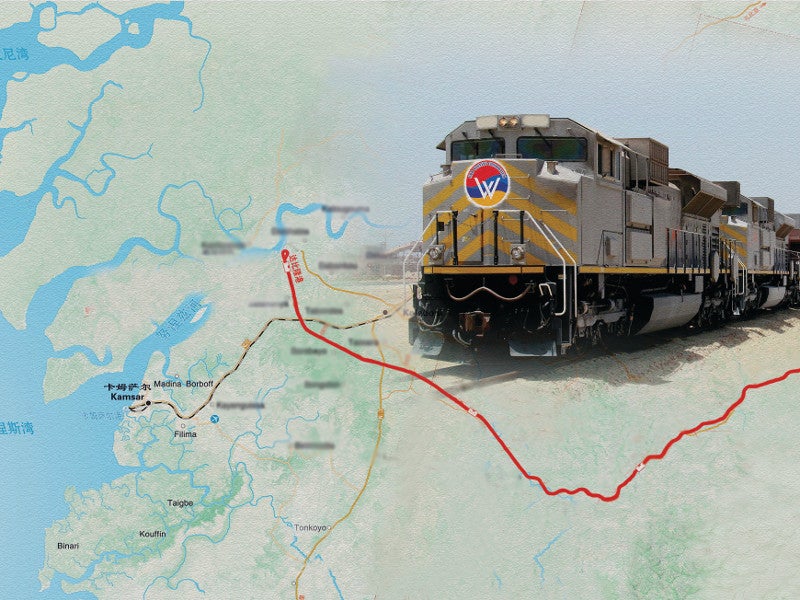

The Dapilon-Santou rail project is a new 135km-long railroad facility being built to connect Santou mining zone and the Port of Dapilon in Guinea.

The project is expected to provide the necessary infrastructure to serve the bauxite enterprises such as Chico along its route. It will also create an agricultural development corridor for promoting the exploitation of fertile that surround the area.

SMB-Winning Consortium is developing the rail line within the Kindia and Boké provinces in north-western Guinea. The consortium includes an Indonesia-based dry bulk shipowner and operator Winning Shipping, a Guinean logistics company UMS and a China-based aluminium producer Shandong Weiqiao. The Republic of Guinea holds a 10% stake in the consortium.

As a developer, SMB Winning is responsible for the design, consultation, monitoring and construction work. The ground-breaking ceremony of the rail project was held in March 2019. The project is expected to be completed by June 2021.

Dapilon-Santou rail project details

The Dapilon-Santou rail project is a part of the SMB-Winning consortium’s $3bn investment that includes a refinery, a 135km railway line and bauxite mining licenses development in the north-west of Guinea.

The railroad will support bauxite transportation from the Houda and Santou II mining areas to the Dapilon fluvial terminal. A total of 23 bridges, two tunnels and six depots will be constructed as part of the rail line. The construction of tunnels and bridges is estimated to cost $1.2bn.

Railroad site prospecting, procurement of material and equipment, lying of track subgrade and production of bridge girders is currently taking place as part of the project.

The first batch of construction materials for the Dapilon-Santou railway project was loaded at Yantai Port in China in September 2019. The consortium is transporting the required materials on a 200,000t bulk-cargo ship WINNING GRACE that is owned by Winning International Group.

Dapilon-Santou rail project benefits

The Dapilon-Santou rail project will enable faster and more efficient transportation of bauxite to the docks in high concentration. It will help to expand the mining zone while reducing the corporate transportation cost.

The cargo transportation at Dapilon port will improve due to the high-capacity railway channel. The project will also enhance the railroad-maritime intermodal logistics system.

There are proposals to merge the rail project into the Guinean national railway transport network and enhance the socio-economic development of the nation. The consortium also proposes to allow third parties to use the rail services.

Contractors involved

China Railway 14th Bureau Group and China Railway 18th Bureau Group won contracts to construct two segments of the rail project in April 2019.

Louis Berger prepared a detailed analysis of the environmental and social impact of the project, as well as the comprehensive environmental and social impact management plan (ESMP).

SMB-Winning Consortium’s integrated project details

In March 2018, SMB-Winning Consortium signed a memorandum of understanding (MoU) with the Government of Guinea for the integrated project in Boké.

With an investment of $3bn, the integrated project is being developed in three phases. The first phase involves the construction of the railway line from Boffa to Boké.

The second phase includes the production and industrial exploitation of bauxite resources in the new mining areas of Santou II and Houda. Phase three will involve the construction and operation of an alumina refinery in the Boké special economic zone.

The refinery will have a capacity of up to one million tonnes per annum (mtpa) and will be powered by a dedicated power plant, featuring advanced slag treatment technology. It is expected to cost between $700m and $900m.