Over the years, Aqua Clean has studied thousands of different cleaning and washing applications, and their associated problems. With this experience, we can offer you the best solutions to different cleaning processes.

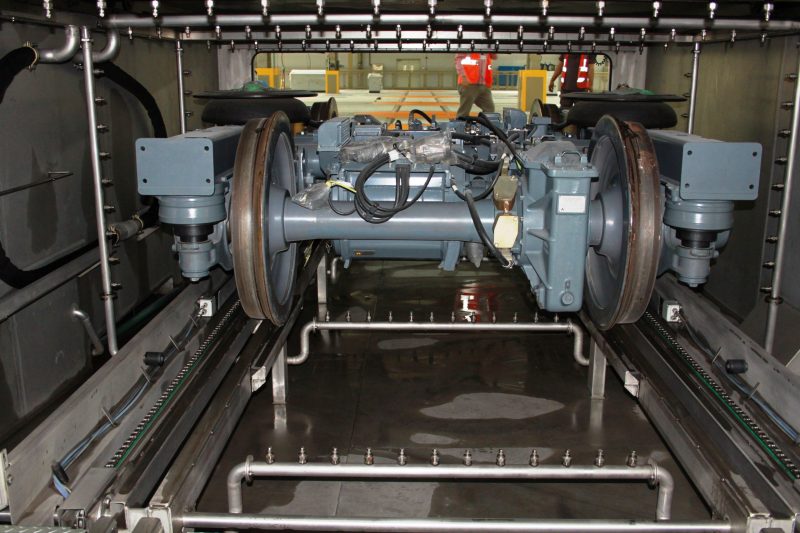

We aim to achieve zero defects between the cleaning machine and the rest of your production line. For railway applications, we offer high-quality bogie, wheelset, and component washers for engine blocks, traction motors, bearings, and other necessary components.

By using equipment with the latest technology, operated by highly skilled personnel, we produce tailor-made and complex metal parts washers, as well as a comprehensive standard range. There are more than 20 standard models in the range, including both spray and full-flow cleaning machines, which can be used to clean various components relating to the rail industry.

AS single-stage machines for rail vehicle components

Aqua Clean’s AS single-stage machines are designed for the aqueous cleaning of small and medium-sized components, when a single-stage cleaning process is sufficient to fulfill the cleanliness requirements. They are mainly used in the engineering industry and rail workshops for the cleaning of metal components contaminated with oil, grease, or solid particulates.

AS machines are manufactured in stainless steel, insulated with mineral wool, and covered with stainless steel cover panels. The machine consists of an insulated, enclosed cabinet with a rotating spray system, a load carriage, a hinged door, and a tank system. The hinged door acts as a load platform when in the open position.

The cleaning process is carried out via a rotating spray system with built-in nozzles. Hot cleaning liquid is sprayed onto the components from all directions, with a high mechanical effect. The liquid is then filtered and re-circulated.

AC single-stage machines

Aqua Clean’s AC single-stage cleaning machines are designed for the aqueous cleaning of medium and large components, when a single-stage cleaning process is sufficient for the cleanliness requirements. The cleaning machines are mainly used in rail workshops and the production engineering industry.

Similar to the AS machines, the AC machines comprise an insulated, enclosed cabinet with a rotating spray system, a load carriage, a lifting door, and a tank system. However, a load platform or trolley can be placed in front of the cleaning machine for loading.

The process is carried out via a rotating spray system with built-in nozzles. Hot liquid detergent is sprayed onto the rail components from all directions, before being filtered and recirculated

When the length of the component to be cleaned is much longer than its width, the AC range can be supplied with an oscillating spray system (OSC), allowing it to effectively clean different rail components.

Multi-stage cleaning machines

Aqua Clean’s AC multi-stage part washers are used to clean medium and large sized components and for more demanding cleaning applications. They are used in rail maintenance workshops for the cleaning of bogies, wheel sets, diesel engines, and bearing housings.

The washers are used for the cleaning and rinsing of machined components prior to assembly. Compressed air blow-off and drying can be applied where necessary. The cleaning process is carried out via a rotating spray system, with built-in nozzles, using hot detergent liquid.

The AC multi-stage range can be automated and integrated into a production line, making it suitable for a variety of rail applications.

When the length of the component to be cleaned is much longer than its width, the multi-stage range can be supplied with a reciprocating spray system.

Basket rotating cleaner machines

Aqua Clean’s basket rotating cleaner (BRC) cleaning machines are intended for the aqueous cleaning of components in baskets. Intricate rail components can be placed in a rotating basket in the machine to be cleaned. Our BRC machines can be used in maintenance rail workshops for the cleaning of bearings and bulk parts.

Aqua Clean BRC cleaning machines are intended for an aqueous cleaning process, consisting of cleaning and rinsing. Blow off and drying can be applied when necessary. The cleaner can also be equipped with a load platform or a manual roller conveyor.

Flooding and spray cleaning

Flooding occurs by spraying cleaning liquid with a high flow and pressure into the bath. The flooding and spraying process creates strong turbulence, and this combination of strong turbulence and a rotating basket allows the cleaning liquid to effectively penetrate inaccessible channels, openings, and blind holes.

This effectively cleans even the most complicated component geometry of railway equipment.

About Aqua Clean

Aqua Clean was founded in 1993, in Finland. Today, there are Aqua Clean distributors in over 20 countries throughout Europe, North America, and Asia. We have agreements with DST-Kemi, from Denmark, which produces detergents.

Aqua Clean’s primary aim is to be a leading provider of component cleaning and provide excellent solutions for the rail industry. The company has a strong international reputation among users who are not only looking for technical solutions to their cleaning problems but also an effective and recent production method.

Our high demand for quality and high-performance technical solutions are important reasons behind our success.