Advanced Measurements Technologies AB (AMTAB) is a Swedish company that offers accurate and sophisticated railway monitoring systems at a low cost of investment to accuracy ratio.

Universal railway monitoring sensor system

Systems can be installed rapidly without interrupting or shutting down traffic. No weight or speed limitations are enforced at the weighing site when in operation.

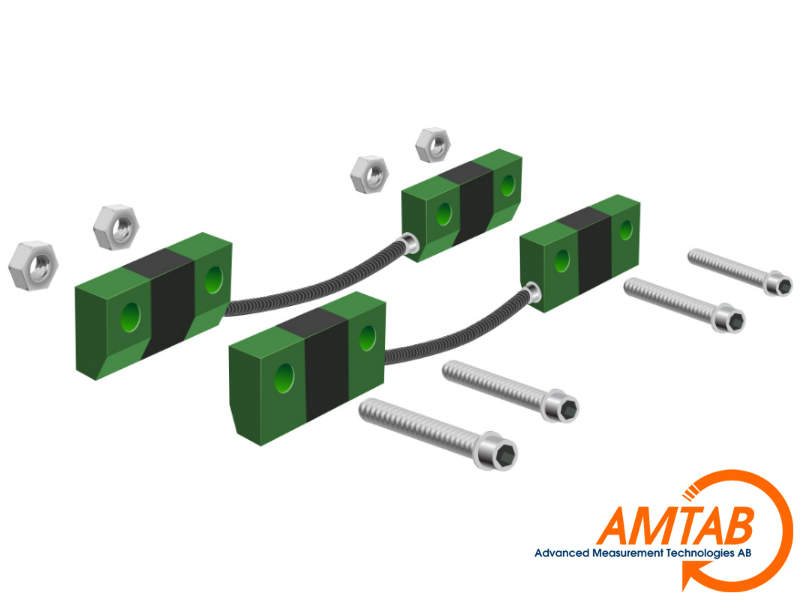

Sensors are attached directly to the track. Designed and manufactured in Sweden, they are extremely rugged for harsh environments and adverse weather (IP 68 and MTBF over 90,000 hours).

The system is modular and scalable and can monitor a large range of parameters. It is a universal turnkey solution that fits all known railway standards.

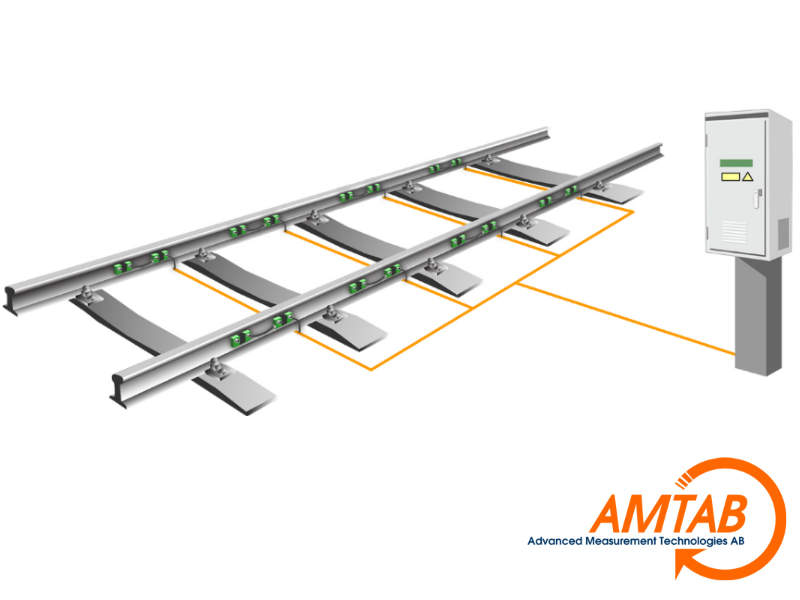

Multiple weighing stations can be connected to a single database and user interface for monitoring gross tonne kilometre (GTK), maintenance and logistics.

Weighing systems for moving railway vehicles

The AMTAB system is capable of detecting the weight of each vehicle with accuracy higher than 0.2% in particular applications. It can detect uneven load and overload on cars increasing operational safety.

It measures speed, direction and axle distance, and when compared to the system’s database, it determines engine and car class.

The system can detect wheel damage and provide data for generating warnings about conditions for derailment.

High-accuracy railway vehicle measurement system

The system has, in principle, no moving parts. The active part of the sensor is a strain gauge sensor, which, through a patented manner, detects the rail’s changes and converts this information into analogue electrical signals.

A fully installed system consists of four weighing points on each rail, which are used to measure and classify locomotives and cars when passing over the weighing station in a speed range of 1km/h – 130km/h.

Raw data from the sensors is processed on-site and immediately transferred to a database via Ethernet or wireless connection. A solid-state backup safeguards in the event of a power or communication interruption to prevent data loss. System can be remotely operated, including system upgrades, diagnostics and maintenance.

Data is processed by AMTAB software and may be accessed anywhere using the web browser provided with the system or in the operator’s own software after integration. Data can be easily integrated with the MySQL data structure.

Railway weighing system register

The system records the site, date and time of the weighing, along with the speed and direction of the vehicle. The number of axles is recorded along with the weight of single wheels and bogie, as well as the wagon and train set.

Uneven loads can be identified, along with broken bogie suspension and wheel defects.

To find out more about AMTAB dynamic measurement and weighing system, fill out the enquiry form on this page.