TGM Lightweight Solutions provides technical weight management and optimisation for rail, aircraft, road vehicles and marine vessels.

The company’s expert engineering and consulting services are based on extensive experience in a broad range of industries, in-depth technical knowledge, and successful project management and implementation skills.

TGM develops specialised weight management and analysis methods, as well as highly effective mass-properties software that allows clients to optimise the weight and cost of their products. By applying a carefully structured process, the company can achieve rapid and measurable results in weight reduction for its customers.

TGM identifies and implements the optimum balance between weight reduction and cost-efficiency for each project. Its highly qualified engineers and consultants offer solutions focusing on weight management and related business strategies, including weight optimisation, lightweight design and cost analysis.

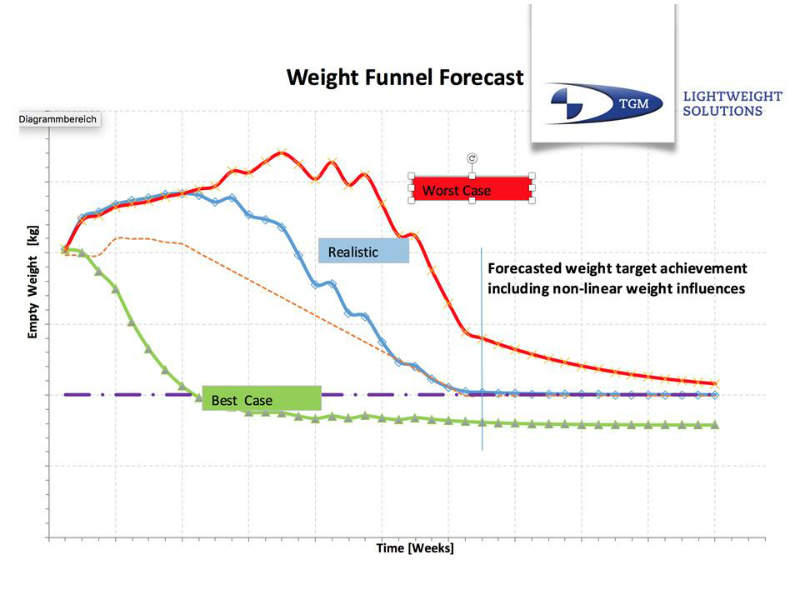

Weight-funnelling concept for weight analysis

TGM offers the approved weight-funnelling concept (WFC), which is a structured weight management method for advanced forecasting of weight and cost from the early development stages until start of production, including integrated weight analysis, reduction and optimisation. It helps the decision-maker to find the most efficient development variant in terms of weight and cost.

The WFC method is based on a mathematical model developed by TGM and assesses and implements new technologies and innovations; including cost and supplier management; structured analysis of the variables influencing weight-related opportunities and risks, as well as the organisational environment in terms of measured key performance indicators (KPI) and the efficiency of the development organisation itself.

All relevant lightweight construction techniques are supported, including system, structure and material lightweight design under consideration of the most cost-effective way of realisation.

With the assistance of Altair HyperWorks, the WFC solution implements all state of the art structural and material optimisation methods.

Consulting services for weight management

TGM’s technical consulting helps clients to make safe and effective choices in achieving their weight and cost targets.

The company focuses on forecasts, targets and supplier-side management, as well as workshops and training.

Lightweight engineering of rail components

TGM provides topological optimisation analysis, ranging from car shell structure to component housing.

The analysis implements an optimal lightweight design during the initial project phases, which affects targeted weights, and reveals optimised load paths, depending on the special mechanical boundary conditions.

The company also offers finite element structural analysis (FEA) and FE optimisation, and identifies weight-saving opportunities.

The required result is to optimise given structures while removing unnecessary features. TGM’s goal is to develop structures that achieve the required boundary conditions while being as light as possible.

Mass-properties software

TGM has developed specialised software applications for weight reduction and management using structured, analytical methods, including:

- Mass-properties software: Weight Data Tool and SmartAct

- Software development and training

- Static load calculations for various bogie configurations

- FEM calculation module for statically indeterminate vehicle systems

- Agil PDCA Cycle development and ISMS Policy Approach

Past projects

Founded by CEO and mechanical engineer Hans-Peter Dahm in 1996, TGM has accrued numerous references, three of which are detailed below.

Firstly, the company successfully cut 1.8t from a rail-vehicle platform project. Each of the weight / axle-load targets was successfully attained thanks to methodical weight management and the application of structured load optimisation to each vehicle assembly.

Secondly, TGM saved 1.6t from an Airbus A380 cabin. Weight overruns on current projects were identified and a weight-recovery plan was implemented for several completed projects. The weight saving increased payload and performance, as well as reduced fuel and running costs.

Thirdly, the company eliminated 80kg from a German car project. The resulting reduction in vehicle weight was a key contributing factor to meeting the project’s demanding CO²-emission targets. Additional benefits included improvements in the car’s driving dynamics and vibration response.