Decnika is an engineering consultancy company, which offers specialised expertise in system design and development for rail vehicles.

The company provides full engineering support on projects from concept to detailed design, and cover areas such as ergonomics, human-machine interface (HMI) design, installation engineering, and 2D and 3D design.

Decnika also develops electrical cabinets and enclosures for rail projects, implements pneumatic systems, and provides structural analysis and cooling engineering for rolling stock systems.

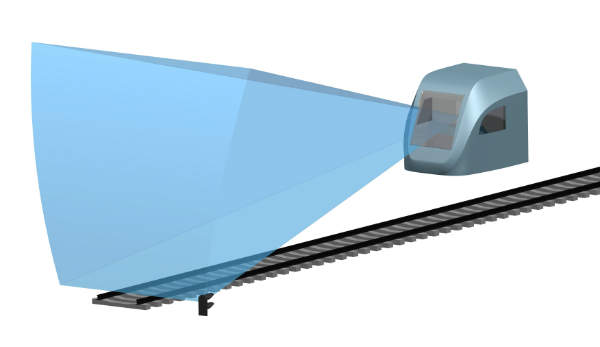

Engineering of driver’s desks and cabs for railway vehicles

Decnika offers a wide range of engineering and design services for driver’s desks and cabs in locomotives, trams or metros.

The company is experienced in preparing driver’s desks for locomotives undergoing cross-border operations.

Decnika’s desks comply with UIC 612 guidelines, and UIC 651 ergonomic and visibility requirements.

Ergonomic driver’s desk systems for locomotives

Large pieces of control and monitoring equipment often hinder the possibility of a high-quality ergonomic configuration.

Decnika focuses on maximising driver comfort and visibility by optimising space. When possible, the company works with equipment suppliers to either reduce or modify the distribution of internal devices, improving the ergonomic quality of driver’s desk designs.

Other critical features of driver’s desk and cab designs include cab climatisation systems, lighting, readability and understandability of pictograms and device texts, and the appearance of desk and cab interior surfaces.

Rail vehicle interior design services

In addition to driver’s desks, Decnika designs the train’s passenger areas, integrating seating design, lighting, climatisation, panelling, doors, handrail design, floor structure, or signage to meet the client’s rail vehicle concept.

The company is experienced in designing composite parts and metallic fixtures to complement the car-body structure.

In this design process, Decnika aims to prevent potential installation errors that can result from the relatively high tolerances these parts are usually manufactured with.

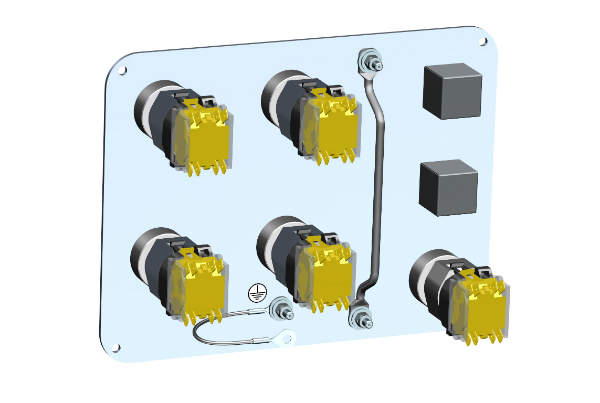

Electro-pneumatic rail vehicle installations

Decnika is experienced in performing electro-pneumatic rail installations, such as compressed air production systems, brake panels, piping connections, sanding or wheel flange lubrication solutions.

The company can also install auxiliary systems for diesel engines, from cooling and lubrication systems, to pre-heaters and auxiliary power units (APU).

For electric traction units, Decnika designs high-voltage cabinets and cabling, low-voltage control cabinets and electric enclosures.

Rail-specific engineering services

Decnika aims to become a fully operational extension of engineering teams developing systems for rail vehicles.

The company’s works with the client from the initial design phase, to the development stage.

During this phase, Decnika relies on its knowledge of key technological areas in the field of rail vehicle engineering, including:

- Welded structures of steel and aluminium

- Bolted joints

- Composite parts

- Pneumatic equipment and piping systems

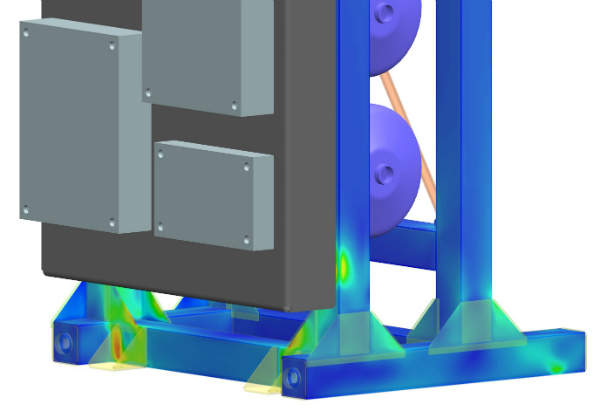

Structural analysis of rail components

To complete the company’s range of engineering services, Decnika offers finite element analysis (FEM) of structural parts, including full structural analysis reports, checking structural integrity to proof loads, service loads (fatigue life analysis), vibrations and bolt integrity.

Finite element analysis reports for rolling stock structures validate the requirements included in the following norms:

- EN 12663 for general structural requirements of railway vehicle bodies

- DVS 1612 for fatigue life of steel-welded unions

- DVS 1608 for fatigue life of aluminium-welded unions

- VDI 2230 for bolt calculations

The company uses Siemens NX CAE with NX NASTRAN to perform preliminary FEM analysis early in the engineering process, and evaluate the structural design options available. This ensures the best option is used, and prevents costly changes that arise when structural analysis is conducted at the end of the design process.

When analysing third party designs, Decnika benefits from NX’s built-in synchronous technology, which allows the company to quickly perform geometry clean-up operations prior to meshing without using the original CAD model.

Decnika can easily modify the original geometry and send detailed 3D files to the customer so they can evaluate the engineering change proposal.

Cooling system solutions for rail applications

Decnika offers cooling system solutions for critical rail components, such as converters, transformers, and traction motors.

The company can also provide clients with bespoke-sized pumps, radiators, fans and blowers.