New thermoplastic materials offer countless possibilities for weight reduction in the manufacturing of railway cars without limiting design and durability. Covestro is one of the world’s leading manufacturers of polycarbonate and polycarbonate blend sheets and uses high-quality polycarbonate and polycarbonate blends from Covestro to manufacture Makrolon® sheets (PC) and Bayblend® sheets (PC and ABS).

Covestro’s polycarbonate and polycarbonate blend sheets are such high quality because the company has a special know-how regarding extrusion processes, uses high-quality raw materials and a stringent quality management system to ensure the comprehensive control of all of its operations.

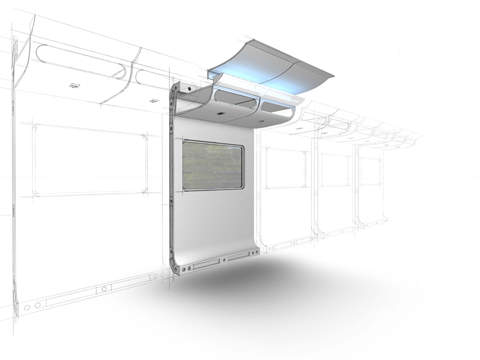

Lightweight polycarbonate sheets for railcar manufacture

Impact-resistant Makrolon sheets are half the weight of glass. Makrolon is backed by a warranty against breakage, which virtually eliminates unplanned maintenance for cracked and broken glass. The windows will not break, which means even in cases of vandalism, the carriages can be kept in use until the next scheduled maintenance.

An advanced coating technology resists weathering and abrasion so previous worries about ageing and scratching are no longer an issue. At the same time Makrolon sheets are lightweight so energy costs are reduced throughout the lifespan of the train.

PC and ABS sheets for railcar seat backs, window masks and ceiling panels

Bayblend sheets can be thermoformed into seat backs, window masks, ceiling panels and many other applications. Bayblend MTX meets EN45545-2 requirements R1 / HL2 and R6 / HL2 up to 2.5mm thickness.

Bayblend MTR is a halogen-free, flame-protected, highly impact resistant and rigid PC / ABS blend developed for the interior trim in railway vehicles. The product satisfies the most stringent requirements with regard to fire behaviour, smoke density and toxicity, including Docket 90A / ASTM E 162 (radiation test on the fire behaviour of floor coverings) and Docket90A / ASTM E 662 (smoke density).

Bayblend FR3030 sheets are made of a halogen-free, flame-protected, highly impact-resistant PC / ABS blend. They satisfy fire protection regulations for use in public transport vehicles acc. NF F16-101 and DIN 5510.

All grades are available in almost any colour. As a result, Covestro is able to offer a versatile range of Makrolon sheets (PC) and Bayblend sheets (PC+ABS) for a variety of applications, which meet all aesthetic, functional and engineering requirements. Makrolon and Bayblend sheets are the solution for mass transit applications.

Thermoplastic sheets for railcar manufacture

Thermoforming is a highly cost-effective production process where thermoplastic sheets are formed under high temperatures. The result is medium to large-sized sheets with very good surface quality and their flexible forming qualities combine low weight with rigidity.

Thermoforming offers significant cost advantages specifically for small to medium production runs when compared to injection moulding, sheet metal and aluminium components, PU systems and sheet moulding compounds (SMC).

Savings of between 30% and 50% are possible, depending on tools and moulded parts but the lower tooling costs are particularly significant.

Advantages include:

- Low tooling costs

- Small, medium and large quantities available

- Freedom of design

- Prototypes and pre-production

- Multi-layer sheet material

- Decorated material

Covestro application managers can assist in finding the best thermoforming partner.

Polycarbonate sheets for mass transit applications

Polycarbonate sheets from the global Covestro network provide the scope to design freely in almost any form and a product can be selected from the product range that will perfectly fit your needs. By applying thermoforming techniques, Covestro polycarbonate sheets can be bent and stretched to the desired shape and used for any mass transit application.

Contemporary furniture designers and artists choose to use Covestro polycarbonate sheets in their creations, demonstrating their versatility. Covestro is also easily accessible as it has a global network of companies, able to serve your needs in any region of the world.