Rica, a division of Irca, provides the railway industry with extensive customised technical solutions for electrical heating systems, used for both rolling stock and switch point de-icing.

Rail coach heating systems

Rail coach heating systems have been developed in response to the strict demands on thermal systems imposed by modern passenger rolling stock.

Heating of footboard entrances and even complete floors is nowadays considered an essential complement to air-conditioning systems, as are boilers for toilets and water tanks, waste-tank heaters, and heating of lubricating oils.

Air-conditioning duct heaters for rail coaches

Air-conditioning duct heaters integrated in the main air-conditioning system provide reliable air for heating railway coaches. Duct heaters have temperature sensors for safety and control, with a large selection of set points. The heater can also be designed to achieve double insulation in compliance with necessary standards.

Under-seat and body-side heaters as well as recirculation vestibule and kitchen heaters use the force of a fan to distribute heat quickly for instant relief from the cold. Mounted along the wall or under the seats, they are designed to be easily connected to the main HVAC system if required, which allow them to be adjusted using the main HVAC controller. An additional control is managed by the heater itself, for when the HVAC is off.

Flexible heating elements for passenger car walls

Passenger car walls can also be heated using flexible heating elements. These flexible heating elements are the result of printed circuit technology. They were developed to solve specific problems in advanced market sectors and they have a large range of applications in the rail industry, such as passenger car wall and floor heating, tank and exhaust pipe heating, and defrosting of carriage entry zones and lifting platforms.

Switch point heating systems for track

Ice or snow deposits on rail track are often a major cause of winter delays. Switch point heating systems guarantee performance to timetables, allowing trains to deliver passengers or goods in all weather conditions.

Whatever the particular point configuration in terms of rail track profile, turnout, and main power source and other parameters, our 30 years’ experience in the field means we can provide different solutions customised to comply with the specific technique in force, and that meet local laws and technical norms.

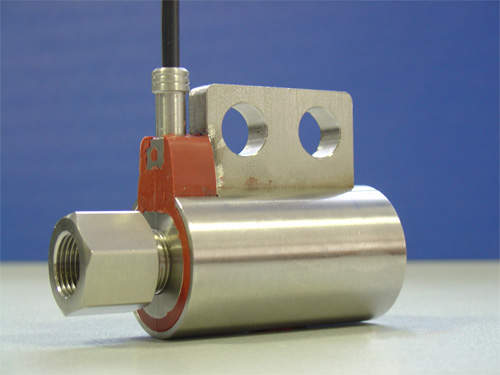

Electrical heating elements for rail track

The electrical heating elements placed along the rail track, which can if needed be operated via an outdoor transformer, are managed by the outdoor switchboards; the command and control may be performed remotely and automatically through the snow detector and surrounding environmental-condition-measuring equipment.

Depending on the particular point configuration, our heaters can be operated either on-site or from the nearest control centre by means of the corresponding remote controls. Determined by the specific voltage required by the relevant national railway system, our heating systems are distinguished by having a lower voltage then is traditional. This is achieved by a voltage transformer, which twists from the switchboard to the heating element.

In fact voltage transformers are required for those heating elements which operate with a voltage lower than 60V. Voltage transformers are even required for those switch points provided by means of self-regulating heating cables, which usually work under 24V tension.