ITSS is a leading manufacturer and supplier of railway hazard monitoring equipment, mainly hot axle box (HABD), hot wheel (HWD) and flat wheel detection (FWD) systems for high-speed and high-traffic railway networks.

The company’s flagship PEGASUS and AGUILA systems use state-of-the-art infrared and fibre-optic technology, which makes these systems extremely reliable even under the most challenging operating conditions. ITSS’s systems come with self-monitoring and predictive analysis features, which can detect potential problems well ahead of time. The systems are further built around redundant and failsafe components to minimise false alerts.

Maintenance overheads are typically low since the systems are modular, auto-calibrating and can be remotely maintained. System components at site can be replaced in a few minutes. ITSS’s systems have been extensively tested, and are certified and designed for compatibility with all important railway standards.

ITSS systems are supplied with robust, networked alert-management software with a full suite of graphical analysis and diagnostics tools. Full TCP/IP support is provided in order to facilitate smooth integration into all existing railway data networks. The software is GUI-based for intuitive and user-friendly operation. ITSS installations can be fully customised to meet local requirements.

In addition to supplying systems, ITSS offers comprehensive local and remote support, as well as replacement services for system components.

Combined hot axle box and hot wheel detection system

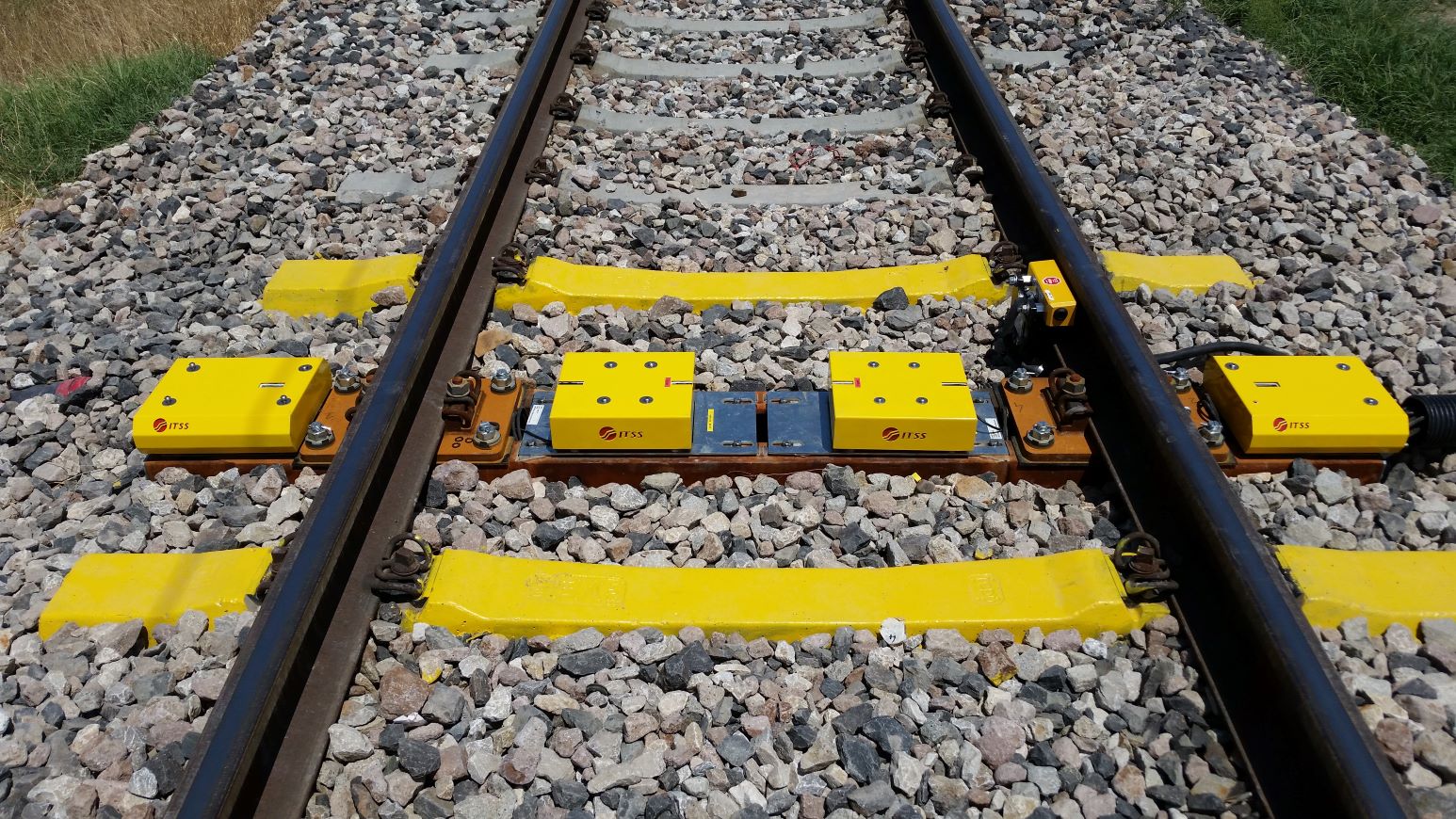

The PEGASUS HABD/HWD system monitors the axle box and brake temperatures of coaches that cross the installation site at speeds of up to 500km/h. The system reports abnormal findings in the form of various configurable alerts to the control room. The low-height infrared scanners of the PEGASUS system are installed in a hollow sleeper at the tracks.

The scanners use multiple beams for enhanced reliability. The scanned values for the individual axles and brakes of each coach of the train are processed by electronic equipment installed in a trackside cabin and forwarded to the control room.

The PEGASUS system has inbuilt, patented intelligent vibration control (IVC) technology which uses special acceleration sensors to prevent premature ageing of the scanners and significantly increase the reliability of the systems compared with older generations of hot box detectors.

PEGASUS offers facilities to add automatic vehicle identification (AVI) and dragging equipment detector (DED) systems with integrated CCTVs. The PEGASUS system can even relay alert messages by radio to the locomotive driver.

Flat wheel detection system

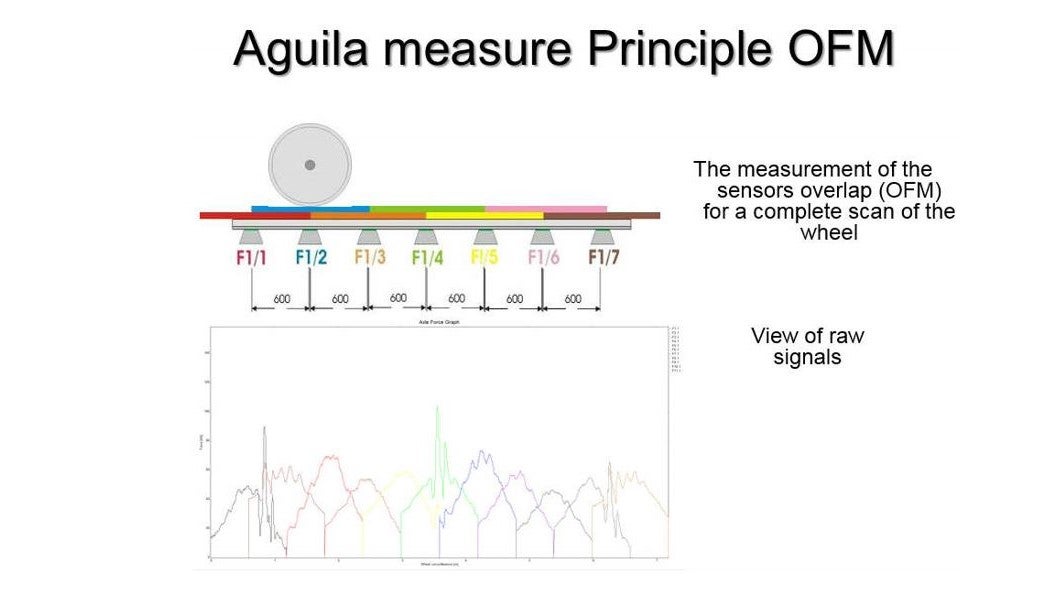

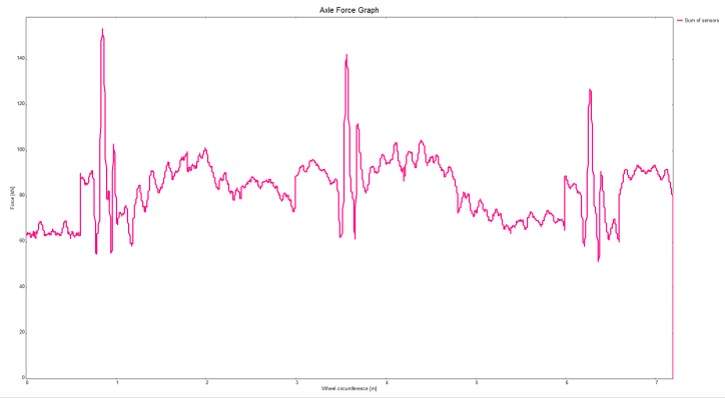

The AGUILA flat wheel detection (FWD) system uses precision fibre-optic technology to detect off-centre wheels and flat wheel sections of coaches with wheel loads of up to 30t. It is designed as a stand-alone system or as a companion system to the PEGASUS HABD/HWD system. In addition to the wheel status, AGUILA can also report ballast status, train weight and overloads.

Coach wheels can be scanned redundantly and direct measurement of the force at the origin guarantees measurement with no blind spots. Like the PEGASUS HABD, the AGUILA FWD has auto-diagnostic and auto-calibration functions. AGUILA can be installed within a few hours and sensors can be replaced within five minutes. The system reports all measured values and alerts to the control room.

Railway monitoring software

ITSS central system software runs on standard Windows-based PCs and offers comprehensive functions for monitoring train status, system status as well as analysis and archiving. The software has several authorisation levels for regular monitoring, maintenance as well as system administration.

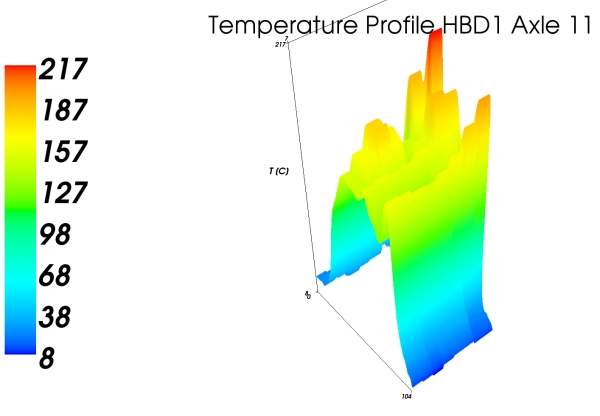

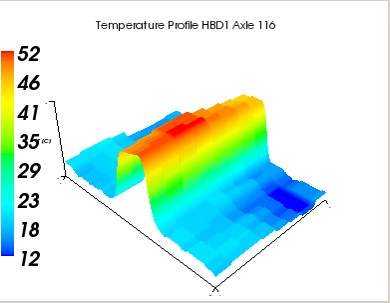

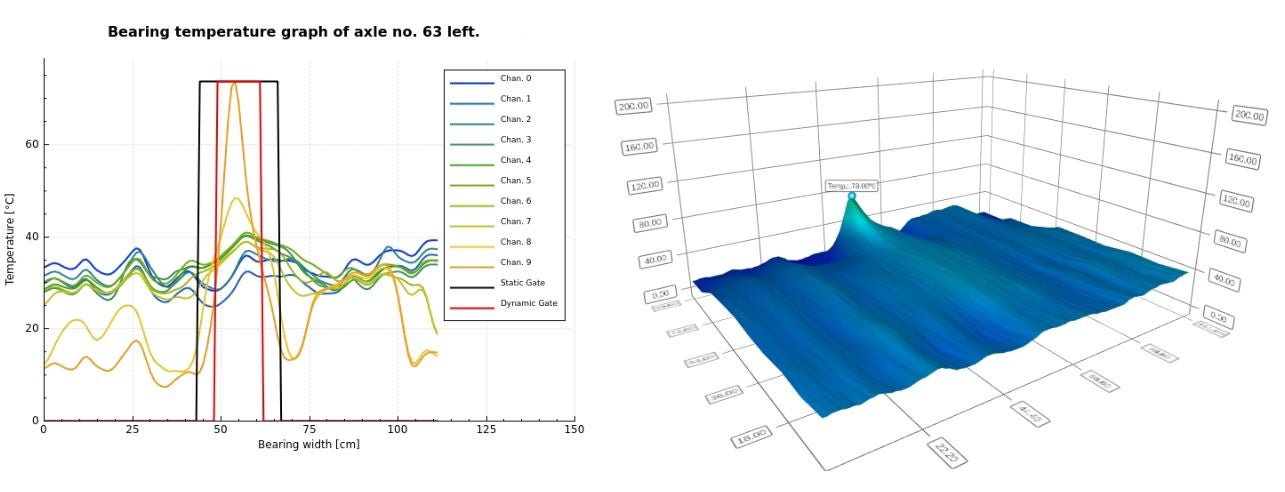

The software is GUI-based for easy and intuitive operation. All system components can be remotely queried and configured. All reported data is archived and can be retrieved on a per-train, per-axle or per-wheel basis. Wheel and axle data can also be displayed as 2D and 3D thermical images and charts.

References

ITSS systems are installed worldwide, including in Australia, Germany, Turkey, Belgium, Uruguay, Italy, Kazakhstan, Morocco, Russia, and Spain.

About ITSS

ITSS is an ISO 9001 certified company headquartered in Madrid, Spain. It was founded in 2005 and is run by railway safety engineers with a long track record in developing hot axle box and hot wheel detection systems. ITSS actively collaborates with railway operators around the world and is committed to enhancing the safety, comfort, convenience and economy of passenger and freight operations.

ITSS offers standard as well as customised hardware and software solutions. ITSS products represent the perfect combination of experience and innovation.