At InnoTrans 2012 RAIL.ONE will present to a broad professional public its expertise in the field of plant engineering. RAIL.ONE offerings will take place under the motto "Build on railway excellence – your sleeper plant on demand".

For decades, the company has exported its experience in the production of concrete sleepers into all time and climate zones of the world – on a turnkey basis, tailored exactly to the requirements of its customers.

The core business of RAIL.ONE is the development, manufacture and delivery of concrete sleepers and railway track systems. Over the last decade, the company has expanded its portfolio of products and services as a result of intensified research and has implemented pioneering innovations for passenger, freight and heavy-haul transport.

On the basis of this comprehensive expertise, RAIL.ONE at InnoTrans 2012 will present a variety of production-plant concepts and new developments in railway track technology.

Focus on plant engineering

RAIL.ONE develops turnkey plant concepts that are individually tailored to the requirements of its customers. These production facilities can be realised either as greenfield scenarios or in existing factory facilities. RAIL.ONE offerings include planning and construction of the plants, as well as commissioning, quality management and staff training.

The company is the only plant designer and builder in the railway field to offer four different production processes to meet the needs of each customer with the ideal solution for their specific requirements. With its unique combination of plant facilities, engineering and years of production experience, RAIL.ONE offers production plants that meet the most stringent of quality standards, while at the same time ensuring maximum business success over the long run.

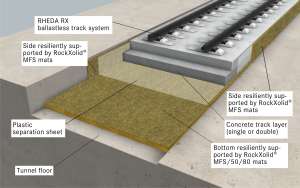

RHEDA RX – ballastless track with noise and vibration attenuation

On the basis of its respected RHEDA technology, RAIL.ONE – together with RockDelta, part of the Rockwool Group – has developed a solution for metro systems that ensures effective reduction of vibrations produced by passing underground trains.

The new RHEDA RX system features RockXolid rockwool mats installed under the RHEDA track-support layer. These mats are characterised by an extremely long life, simple installation and outstanding attenuation of structure-borne noise. In addition, proper selection of mat type achieves clearly defined track elasticity.

This enables the use of simple and cost-effective fastening elements and, at the same time, prevents the occurrence of problematic resonances. RHEDA RX also offers definite benefits in installation, for example fast and cost-efficient construction progress in tunnels.

RHEDA RX is environmentally compatible, since all its components can be recycled. With its properties, the RHEDA RX ballastless track system represents the ideal solution for ecological and, above all, sustainable passenger transport of the 21st century.