DCD Metpro, a division of DCD Group, designs, develops and manufactures on-tread, asbestos-free composite railway brake blocks and brake shoes for on-tread braking of diesel and electric locomotives, freight wagons, passenger motor coaches, passenger coaches and a wide variety of rolling stock used in the mining industry.

Design and development of backing plates, brake blocks and friction materials

DCD Metpro is committed to the design and development of the most suitable and cost-effective backing plates and brake blocks for every application. Backing plates are designed with the particular end use in mind, taking into account the interference fit into the brake block holder.

Design aids include strain-gauge measurements and finite element analysis, producing end products which have sufficient strength and infinite fatigue life without requiring expensive manufacturing processes such as welding.

Composite friction materials are developed for a wide range of applications, ranging from high friction AAR M-926 equivalent freight brake shoes to low friction applications and direct cast-iron brake block replacement. To this end Metpro has laboratory mixing equipment, manufacturing presses and curing facilities.

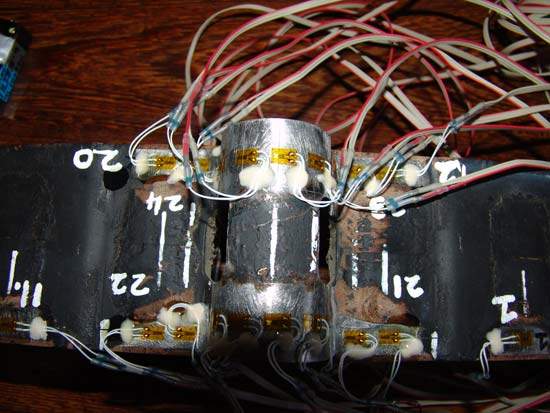

Full-scale railway brake dynamometer

Metpro uses a full-scale railway brake dynamometer, able to simulate the momentum and inertia of a wide variety of railway vehicles by speed and torque control of the hydraulic drive motors.

The dynamometer is capable of 14,000Nm torque and 140km/h applications. DCD Metpro also employs the services of the best composite and friction material development capabilities of universities and institutions in our area. This ensures accurate and purpose-specific friction characteristics, combined with suitable mechanical properties and low wear rates. Products are also designed to conserve rolling stock wheels and be environmentally friendly.

Manufacturing and supply of composite railway brake blocks

Metpro has the capacity to manufacture up to one million composite railway brake blocks per year. Manufacturing is performed by controlled compression moulding and controlled secondary curing. Information can be stamped, painted or printed on the product. Brake blocks are packed and shipped according to our customer requirements.

Customers include railways and railway support companies in South Africa, sub-Saharan Africa, Australia, Europe and the US. Stock management is performed according to customer needs and usage rate, ensuring a continuous supply of composite railway brake blocks at the most cost-effective stock levels for our customers.

ISO-certified manufacturing processes for railway brake blocks

Quality control is carried out according to the ISO 9001:2008 system, for which DCD Metpro is duly accredited. DCD Metpro is serious about environmental management and conservation, and is certified according to the ISO 14001 environmental management system. Looking after the health and safety of our employees, we are accredited and certified with the ISO 18001 occupational health and safety management system.