In early 2015 all of IMI plc’s fluid power businesses were brought under one heading, IMI Precision Engineering. IMI Precision Engineering is the new trading name of Norgren, and the world-class range of products has become IMI Norgren, IMI Buschjost, IMI FAS, IMI Maxseal and IMI Herion.

The new name and brand identity is just part of a long-term commitment, including new investment in manufacturing and the supply chain, as well as innovation and new product development.

IMI provide high-performance products, and the reliability which comes from world-class manufacturing and a sales and service network across 75 countries.

For over 30 years, IMI Precision Engineering has delivered robust, reliable and bespoke solutions to the rail sector. With a true understanding of the daily issues faced by rail operators and original equipment manufacturers, IMI Precision Engineering designs for the precise needs of the rail industry, at:

- Temperatures ranging from -40°C to 80°C (-40°F to 176°F)

- Voltage tolerances of + / -30%

- EN61373 category 1 class A and B vibration resistance

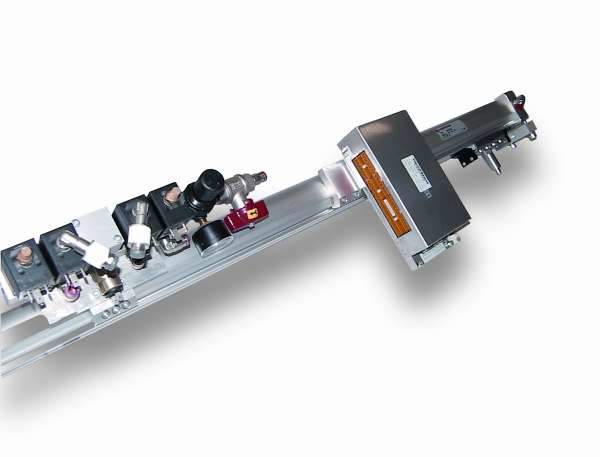

Air preparation equipment

As the inventor of the automatic airline lubricator in 1927, IMI Precision Engineering has a deep insight into the air preparation problems facing many industries, especially rail.

Engine-driven air compressors used on rail vehicles are known to pass significant amounts of oil and carbon deposits into compressed air systems.

IMI Precision Engineering’s multi-stage filtration system, fitted to vehicles throughout the world, has resulted in significant improvements in particulate and oil removal, leading to better durability and reliability, and significant savings for operators on installation and maintenance costs.

The innovative Adsorbent Media Tube (AMT) dryer, with a life span of six years, marks a significant advance over both desiccant and membrane systems. Vibration resistant and suitable for both horizontal and vertical installation, the result is a ‘fit and forget’ product which dries better than any current solution. This improves reliability, reduces unplanned downtime and helps drive down the cost of ownership.

Pneumatic pantograph control systems

With high-speed trains becoming faster, pantograph systems are expected be more responsive to height variations. IMI Precision Engineering designs and manufactures pneumatic systems that attach to pantographs, and retract quickly, reliably and accurately from the overhead power cables when required.

All solutions are small enough to fit within the existing footprint of the pantograph, giving customers a cost-effective design, while also providing unrivalled performance with a rapid, quiet and stable operation, across a wide temperature range of -40°C to 80°C.

Water control systems

IMI Precision Engineering can call on over three decades of experience in supplying high performance solenoid valves for water systems on board rail vehicles. This includes buffet and restaurant cars, drainage and sewage systems, and toilet flushing applications.

The company also offers high-performance automatic drain valves to protect on-board water systems from freezing when stationary and during extremely low temperatures. This proven technology is designed for endurance, is highly responsive to temperature changes, can be easily retro-fitted into existing applications, and easily maintained without disturbing existing pipe work

Door and step systems

Whether external or internal, electrical or pneumatic, IMI Precision Engineering offers solutions complete with control systems and actuators for various on-board door applications.

All IMI Precision Engineering’s door systems easily surpass the 30min fire barrier requirement, and do not allow passenger entrapment, as well as being reliable, safe and competitive.

IMI Precision Engineering also provides door step actuation systems for the world’s leading companies. Customised solutions, based on sliding and rotary actuation, ensure complete reliability, durability and safety.

Mirror control

IMI Precision Engineering has supplied the global rail sector with complete rear view mirror and control systems for more than 10 years. Fitted to both sides of a train, and used to allow the driver to check movement of passengers in the train station, the mirror retracts to the train body for protection once the train reaches 20kph. IMI Precision Engineering offers bespoke solution to suit individual needs as well as complete solutions including mirror assembly with mechanism, pneumatic or pneumatic / electric actuation and control

Coupling and nose cones

IMI Precision Engineering’s special cylinders and customised control systems for carriage coupling / uncoupling are specifically designed to deliver reliable performance, reduce complexity and size, and meet low temperature needs.

Freight systems

Designed for the automated control of freight top hatch and bottom doors, IMI Precision Engineering’s pioneering solutions provide safe, efficient filling and unloading. They provide ease of use and welcome flexibility for customer’s rail operation, as well as helping lower the total cost of ownership.

About IMI Precision Engineering

IMI Precision Engineering is a world leader in motion and fluid control technologies. Wherever precision, speed and engineering reliability are essential, IMI Precision Engineering delivers exceptional solutions which improve customers’ productivity and equipment efficiency. Part of IMI plc, IMI Precision Engineering has a sales and service network of over 75 countries, as well as manufacturing capability in the UK, Brazil, China, the Czech Republic, Germany, Mexico, Switzerland, and the US.