Hegenscheidt-MFD manufactures machine tools and equipment for railway wheels and wheelsets, including underfloor, mobile and portal wheel lathes, wheel diagnostic systems and re-railing components.

The company focuses on the development, finishing and supply of wheelset machinery and systems.

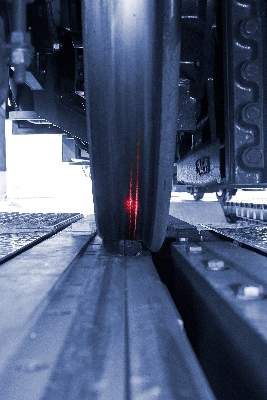

Underfloor wheel lathes

Based on the latest technology, Hegenscheidt-MFD’s underfloor wheel lathes are suitable for a variety of rail vehicles, ranging from high-speed to local trains.

The computer numerical-controlled (CNC) machines guarantee cost-effective, precise and fast operations, from re-profiling wheelsets to machining brake disc configurations.

Hegenscheidt-MFD underfloor wheel lathes are available in different configurations for axle loads up to 40t, depending on the customer’s requirements.

Mobile wheelset re-profiling systems

Hegenscheidt-MFD’s patented mobile, high-value MOBITURN® wheelset lathe can be brought to various locations via rail or road.

Once it has been positioned on the track network in a workshop, the re-profiling system is brought from its standby position on the track network to the respective location when required.

Offering specific advantages, MOBITURN® provides savings in wheelset re-profiling when compared to conventional underfloor wheelset lathes.

Hegenscheidt-MFD also offers customers the option of having their wheelsets re-profiled at their own plant. To do this, a MOBITURN® can be provided with operating personnel and the required wear parts and accessories.

Portal wheel lathes

Hegenscheidt-MFD offers different types of high-performance portal wheel lathes for medium to ultra-heavy machining.

With its portal-shape design, the machine base is suitable for continuous roll-through operation. Feeding is also possible in roll-in / roll-out operation if required.

In addition to turning the profile for new / existing wheelsets, wheel discs can be machined both on the outside and the inside. Machining brake discs is also possible along with other special machining operations.

Portal wheel lathes are also offered with friction roller drive capabilities, which prevent all driver or clamping marks and increases safety, particularly for wheelsets on high-speed trains.

Wheelset diagnostic systems

Hegenscheidt-MFD offers fully automatic monitoring systems for wheelsets in continuous operation using modern, efficient measuring methods and documentation in a database.

The system monitors stringent tolerances and operating limits that are required for increasing speeds and enhanced safety, travelling comfort and operational reliability.

The modular system design allows economic adjustment to the measurement requirements of the customer.

Light-metal re-railing systems

For the recovery of derailed vehicles, Hegenscheidt-MFD is the global market leader in manufacturing and selling state-of-the-art re-railing units.

The company’s re-railing equipment is currently making a contribution to rail transportation in more than 100 countries.

Hegenscheidt-MFD re-railing equipment also uses a double-acting re-pressure system that offers lifting, lowering, pushing or pulling capabilities with millimetre accuracy.

The company applies the highest safety requirements to the re-railing system for ease of operation, and simplicity in handling, robustness and stability under load.

Turnkey wheelset, wheel and axle lines

Hegenscheidt-MFD is part of the Niles-Simmons-Hegenscheidt (NSH) Group, which combines more than 175 years of experience of machine tool construction in Germany and the US.

The NSH Group carries out the planning, modernisation and realisation of complete maintenance depots and production lines for a fully automated workshop for wheels, axles and wheelsets. These lines can be designed for both new production and the repair and maintenance of workpieces.

Regardless of whether a manual or fully automated transport, Hegenscheidt-MFD delivers a precisely tailored solution. From project planning to turnkey delivery, the company is a competent and experienced partner.

About Hegenscheidt-MFD

For many decades, Hegenscheidt-MFD has been dedicated to the construction and development of wheelset lathes.

Since 1950, the company has installed more than 2,000 wheel lathes and supplied products to more than 100 countries worldwide. These include underfloor, flat-bed and portal-design machines, as well as universal wheelset lathes.

The production programme also includes an automatic diagnostic system for measuring the wheelset condition in an override mode.

Complemented by world-class manufacturing sister companies from the NSH Group, Hegenscheidt-MFD supplies complete turnkey solutions for wheel and wheelset manufacturing and maintenance.

Customers are supported by technical sales and service offices in Germany, the US, China, Russia, India, South Africa, Australia, and Mexico.