Officine Meccaniche BBM is a worldwide leading company specialised in engineering and manufacturing of railway workshop equipment and rolling-stock maintenance production equipment.

Rolling-stock maintenance production equipment

Our range of rolling-stock maintenance production equipment includes machines for mounting and testing wheelsets, two and three-axle bogies and springs for railway and metro. Moreover, we can provide bogie and wheel drop systems as well as ultrasonic equipment, bogie running testing benches and lifting devices.

Hydraulic wheel presses

BBM hydraulic wheel presses are available with the following features:

- Pressing force of 1,000kN up to 6,000kN

- Single or double cylinders

- Perfect centring of the wheelset during the mounting and dismounting process

- Pre-fitting stand

- Loading and unloading operations by means of a manually operated or fully automatic carriage

- Automatic component positioning by means of a measuring device mechanically or laser operated

- Mounting and dismounting of six components (two wheels and four brake disks) with a single positioning on the wheel press

- Standard roll-in or pass-through design

- Automatic recording of mounting curve, radial and axial run-out and back pressure test of each mounted component

Hydraulic wheel presses from BBM are fully computer controlled.

Bogie testing stands

The BBM bogie testing stands, used in customer workshops for production and maintenance of coaches and locomotives bogies, are available with bogie axle and/or wheel load tests; pneumatic system for air-tightness tests; bogie dimension tests (wheel gauge, axle parallelism, axle distance and wheel diameter); height-of-bogie tests; tilting tests; and automatic calculation of shim plates.

Bogie testing stands from BBM are fully computer controlled and contribute to delivering technically accurate bogies.

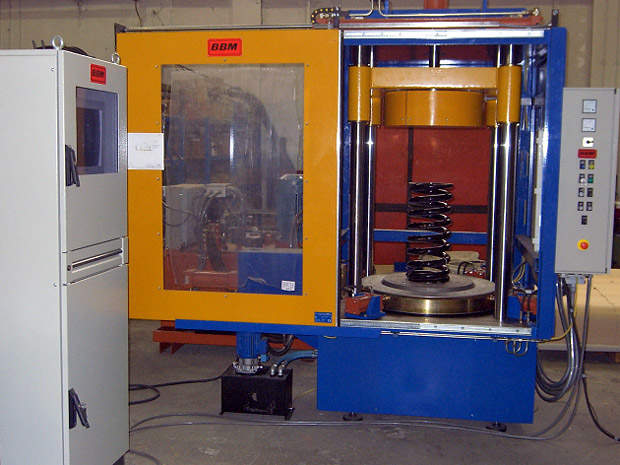

Spring testing press

The BBM spring testing press can be used for testing coil and leaf springs. Tests can be performed with dedicated machines, one per each type of spring, or with a single, integrated, universal solution.

The spring testing machines are available with the following test features:

- Height spring free loaded (quote L0)

- Height spring under loaded (quote L1)

- Load test

- Measurement of chasses (direction, module and sense)

- Diagram compression force/stroke

Bogie and wheel drops

The BBM bogie and wheel drops (which can be of screw or scissor type) can be used to remove bogie or wheelsets while the train is located and supported over the table top. The bogie (or wheelset) is disconnected, lowered, transferred laterally and raised to a release track. It can then be moved to a maintenance area where inspection and repair can be performed quickly and efficiently.

Bogie running testing bench

The BBM bogie running testing bench, able to work with both trailer and motor bogie for maximum speeds of 300km/hr, is available with the following test features: vibration, temperature, noise, and current/voltage test for motor bogies.

ISO-certified provider of railway workshop equipment

Formed in 1965, BBM has long experience with large worldwide companies to whom it offers professional service, pre-sale advice, planning, installation and aster-sales service.

BBM’s quality and safety management systems are certified to EN-ISO 9001:2008, EN-ISO 3834-2 and DIN18800.