Amsted Rail

Freight Car Brake Systems for Railways

Subscribed

You have successfully submitted your enquiry. Someone from our company will respond ASAP

About Us

Amsted Rail specialises in brake and coupler components for heavy haul freight railcars and locomotives. Our company manufactures advanced products that meet the requirements of the demanding heavy haul freight industry.

Freight car manufacturers and rail operators worldwide depend on Amsted Rail to deliver products that reliably haul heavier loads over longer distances. Supported by more than 100 years of experience, Amsted Rail was the first company to attain the Association of American Railroads (AAR) M-976 performance standard and it strives to continue raising the levels of performance.

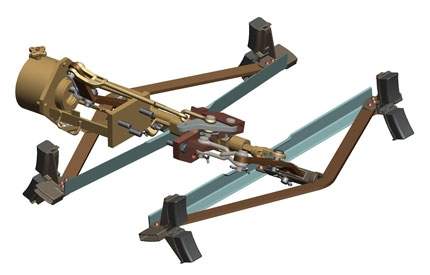

Truck and body-mounted braking systems for railways

Amsted Rail-Faiveley specialises in truck and body mounted braking systems, in addition to a complete line of hand brakes, empty load sensors and brake cylinders. All products are approved by AAR and our global presence allows us to swiftly respond to specific requirements from customers.

Lubricants for rail breaking systems

Amsted Rail’s wear prevention products can save money in replacement costs on components such as brake beams, center plates or bowls, couplers, yokes or brake rods. Amsted Rail’s Hollube® and Hollamax™ products are made with an advanced plastic and reduces wear by more than 80%.

Tapered roller bearings for freight railcars

In 1949, Amsted Rail founded Brenco® to produce journal bearings for freight railcars. In 1959, the company received conditional AAR approval for the tapered roller bearing, Brenco’s signature product.

Millions of Brenco bearings provide reliable service in one of the world’s toughest environments and the company’s reputation for quality and consistency has set the bar for its industry competitors.

Micro-alloy wheels for locomotives

An integral part of Amsted Rail, Griffin® is more committed to industry-leading safety and innovation. The latest development is Griffin’s patented Micro Alloy® wheel, which provides a greater level of strength at higher temperatures, resulting in fewer wheel-set replacements and a significantly longer wheel lifecycle.

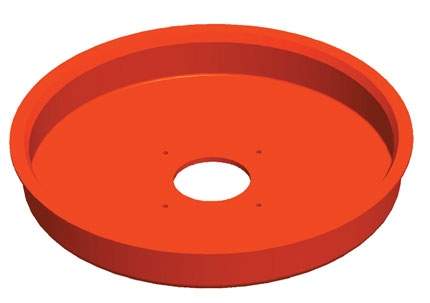

EPA-approved pellet car systems

Amsted Rail provides highly adaptable pellet outlet gates and hatch covers. They also manufacture a wide range of empty-load devices, slack adjusters, bogie assemblies and truck-mounted brakes (TMB). Our products have been approved by the ARR and the US Environment Protection Agency (EPA).

Cushioning units, drawbars and couplers

Amsted Rail’s wide product range allows clients to obtain their components from a single supplier. The company provides integrated systems engineered to effectively reduce impact stress such as AAR-approved cushioning units, drawbars and couplers, as well as the market’s strongest integral cast draft sills and draft gear.

Contact Details

Website

Email Address

Address

Suite 5300,

Chicago, Illinois,

60606,

United States of America