Fairfild has been providing high-quality power resistors to many industry-leading railway industry suppliers since 1974.

Key rolling stock manufacturers continue to work with Fairfild because of its experience in the production of sealed resistors, so they are designed to endure extreme conditions to which rolling stock is exposed such as water, salt mist and dust.

Sealed resistors for extreme railway conditions

Fairfild’s most popular product is the RFK, which became a standard component in various converters, both for traction and auxiliary systems, in the last 20 years.

The RFK series comprises wire wound resistors sealed into aluminium cases, enjoying an IP-66 degree of protection. The RFK series is specifically designed to last more than 30 years in the critical operating conditions typical of rolling stock such as pollution, extreme climatic exposure, moisture, and vibrations.

From 2003 to 2018 a total of 25,277 RFK/S resistors have been installed on trains around the world, accumulating a total of 700,118,910 hours of operation and serving various functions, including precharge, discharge, charge, damping, and over-voltage protection.

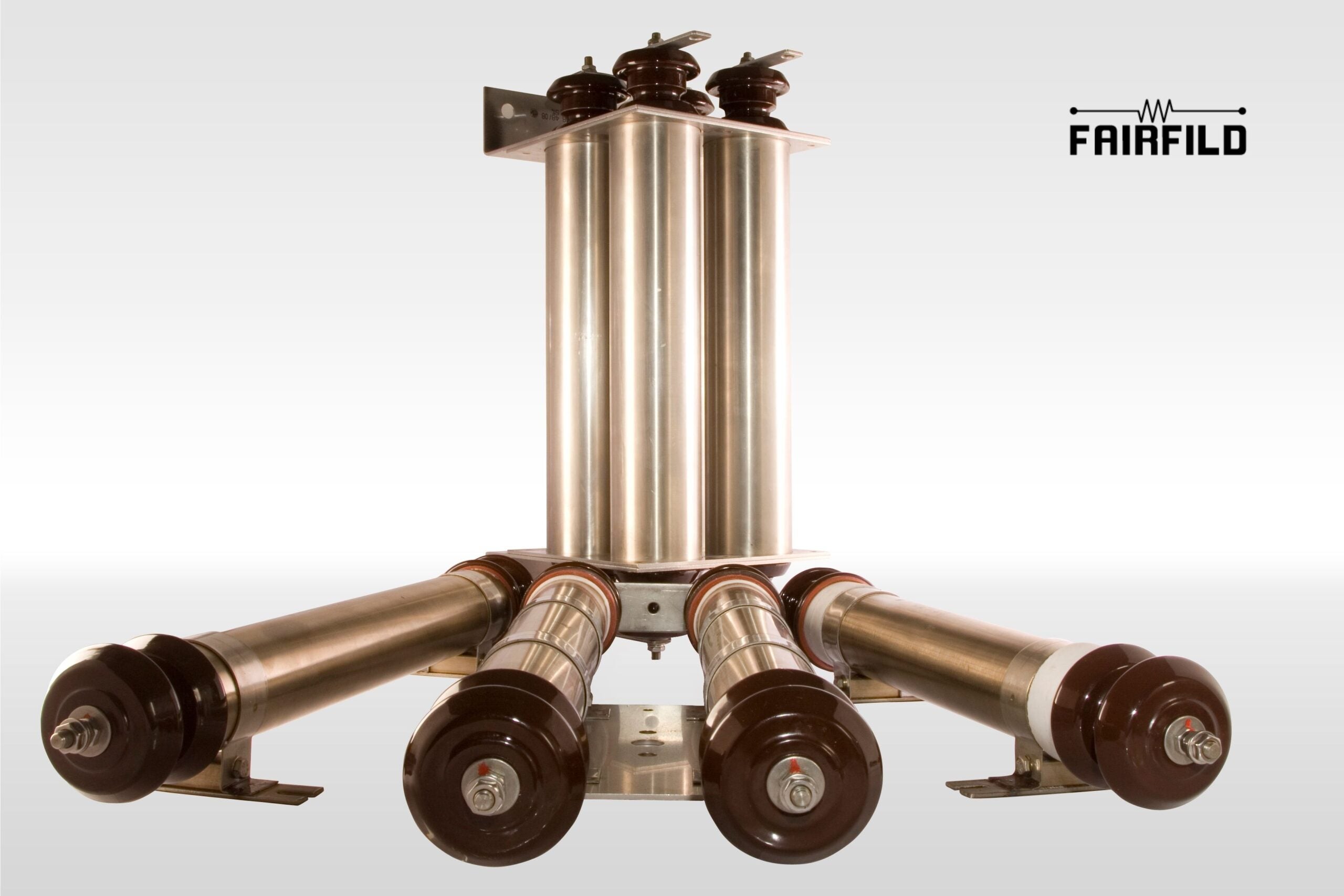

Resistors for charging / discharging capacitors

Fairfild’s resistors are often employed in the capacitor / inductor filter circuits used in the railway sector.

By limiting the current going into capacitors (during charging) and coming out of capacitors (during discharge), they offer crucial help in preserving the integrity of capacitors themselves, as well as other elements in the circuit.

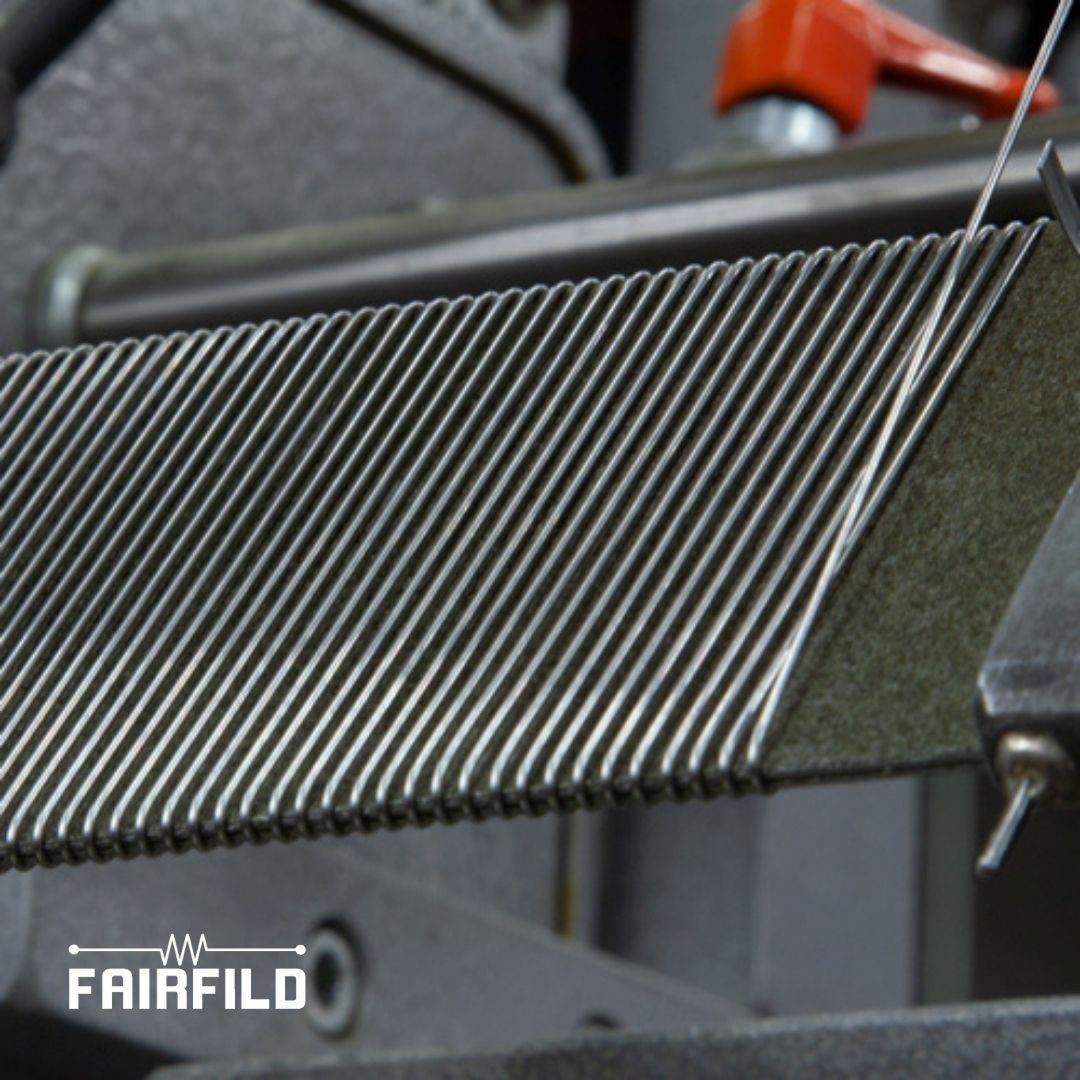

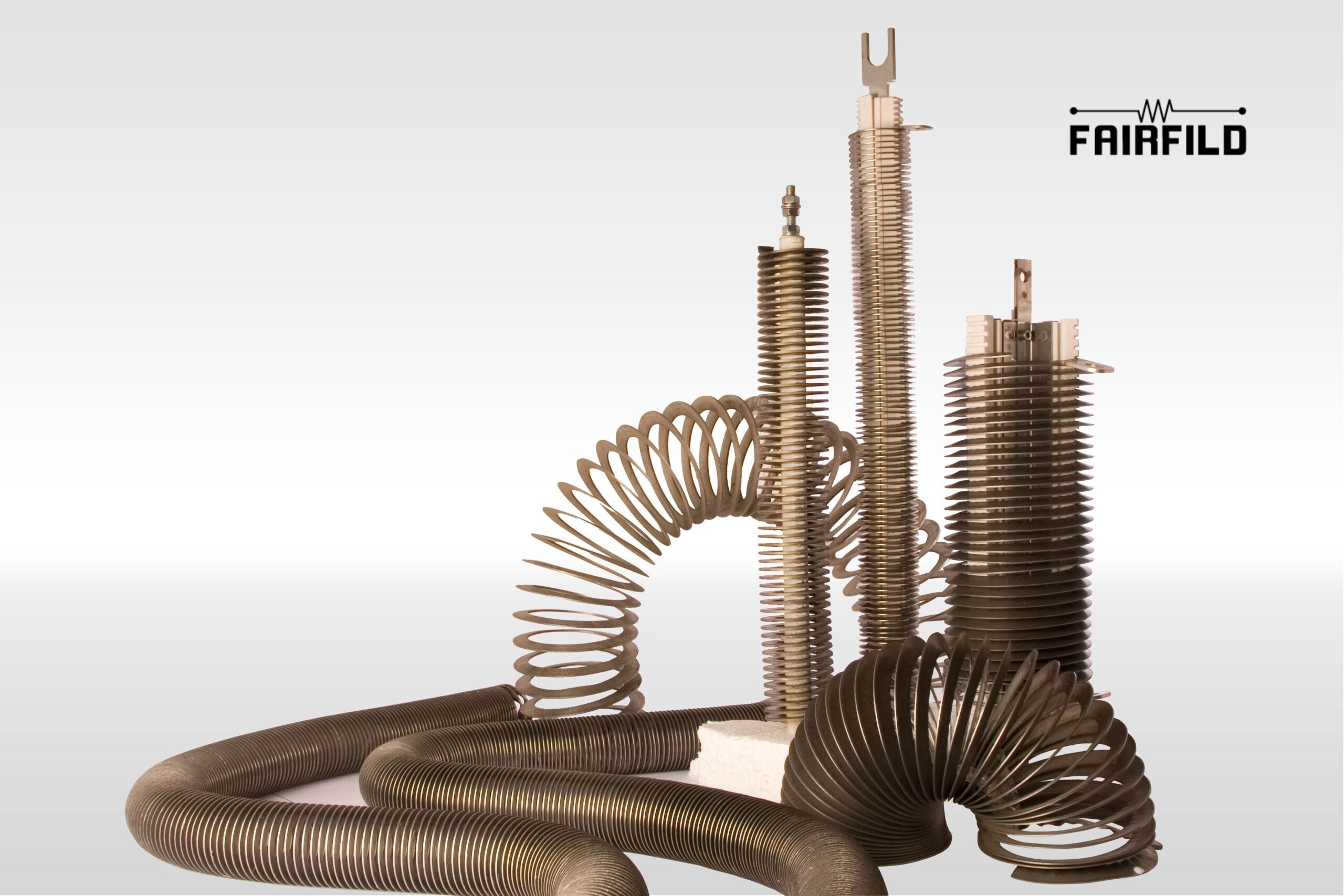

Rolling stock dynamic braking resistors

Fairfild produces a wide range of dynamic braking resistors for rheostatic braking systems.

The variety in designs and technical specifics allows the company to provide braking resistors that can be mounted in any position of locomotives and wagons, including on the roof, under the floor or on the inside. Such a variety also ensures the quick development of custom solutions whenever required.

Snubber resistors for electric traction systems

Reducing power dissipation in power electronics switching networks, snubbers are fundamental in electric-driven tractions systems. Fairfild’s resistors have long been proving themselves as components of resistor-capacitor (RC) circuits in this field, covering an extensive range of power ratings and ohmic values.

Load banks and dummy loads

Over the years, Fairfild produced several custom-made load banks dedicated to the testing of locomotives and generators. Our engineers are always available to develop new projects or recommend the most appropriate resistive elements for devising one, according to client needs.

About Fairfild

As part of the Telema Group, Fairfild combines the reliability of a big industrial group with the customer dedication of a medium-sized firm. Operating since 1974, the company has worked with key rail industry players such as Alstom, Bombardier, Hitachi, Mitsubishi, and Skoda.

Fairfild’s clients can count on the company’s:

- Excellence: Substantial investments in R&D, especially in the optimisation of the production line, allows clients to receive flawless power resistors at a very competitive price.

- Punctuality: The wide range of resistors available in stock allows a quick design and delivery of customised solutions.

- Reliability: Thorough inspections and product-testing in Fairfild’s state-of-the-art laboratory means that the company can vouch for the actual (as opposed to nominal) performances of its resistors.

Fairfild’s commitment to these values is reflected in its vast list of references in the rolling stock market, as well as in the ISO 9001: 2000 and UL certifications, held from 2000 and 2004 respectively.