Ensuring the provision of adequate mobility services to passengers within major urban centres is considered to be one of the greatest challenges of our time.

In particular, megacities with millions of inhabitants all over the world are growing at such a rapid rate that often infrastructure development cannot keep pace with population growth.

New, urban transportation concepts are required to convey millions of people through the growing metropolitan areas on a daily basis.

Public transport solutions help to reduce congestion on overcrowded roads while, at the same time, providing a mode of mass transportation that is low in noise and pollutants.

Japan, which already has a well-developed infrastructure network, is a trailblazer when it comes to urban public transport.

So it comes as no surprise that the Japanese railroad industry is starting to play a bigger role on the international stage, and is bringing its experience to bear in traffic infrastructure projects across the globe.

Continental can help in this endeavour. The technology company based in Hanover, Germany, is a strong partner of the global rail vehicle industry and works with leading original equipment manufacturers to develop innovative technology concepts for the rail transport of tomorrow.

The free trade agreement that Japan signed with the European Union (EU) in August 2017 is also making future cooperation easier.

Continental will be attending the Mass Trans trade fair in Tokyo (29 November to 1 December 2017), where it will be exhibiting its technology in the German Pavilion (booth D-04-5).

Solving technological challenges in railway engineering

For Continental, the railway engineering industry is a key and strategically important industry, offering a range of growth opportunities for innovations and technologies.

Continental’s ContiTech division develops railway engineering products that are not only robust and durable, but also help to significantly enhance safety.

When it comes to the bogie of the carriage or locomotive, air-conditioning and heating systems, or the interior trim, the company’s experts develop holistic solutions that overcome many of the technological challenges currently facing rail vehicle manufacturers.

In addition to primary and secondary suspension systems and rubber-metal parts, its portfolio, which is being refined and expanded all the time, encompasses products such as folding bellows and hoses.

Continental’s material expertise goes way beyond just rubber; with innovations in lightweight design and the integration of sensor technology in its products, Continental is seeking to be among those helping to shape the future of the industry.

This is why the technology company has been involved in numerous research projects over the years aimed at making railway engineering safer, quieter and more comfortable.

Solutions to suit local requirements

Continental provides its customers and partners with a comprehensive service ranging from advice and design development all the way through to air spring replacement support.

Continental’s experts for the rail vehicle industry are based all over the globe and have a precise understanding of customers’ local requirements.

This allows the company to develop products that also meet strict specifications.

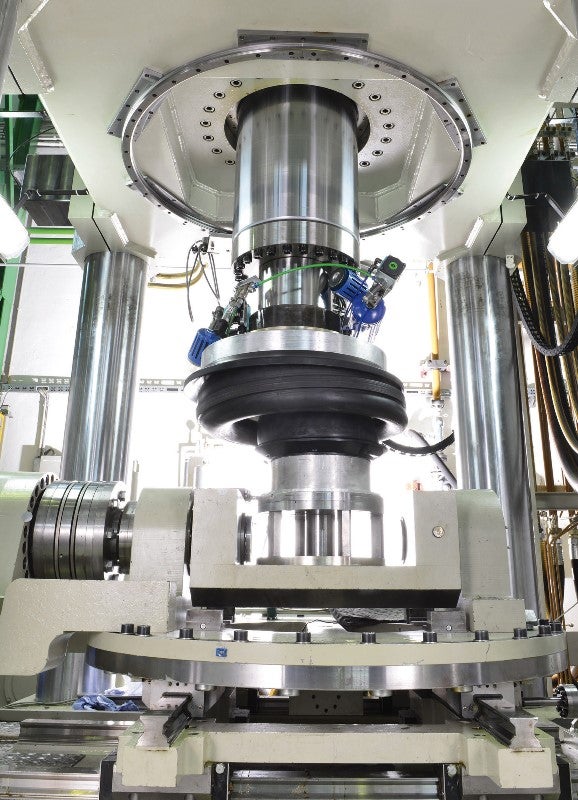

This development expertise is also aided by the accredited test laboratory for rail vehicle air spring systems, which is operated by the ContiTech division in Hanover, Germany, and is the first of its size and testing capabilities the world has ever seen.

Twelve testing procedures that are important to the rail industry have DIN EN ISO/IEC 17025 certification.

The test laboratory has been fulfilling the highest requirements for many years with certification in accordance with ISO 9001, TS 16949 and IRIS.