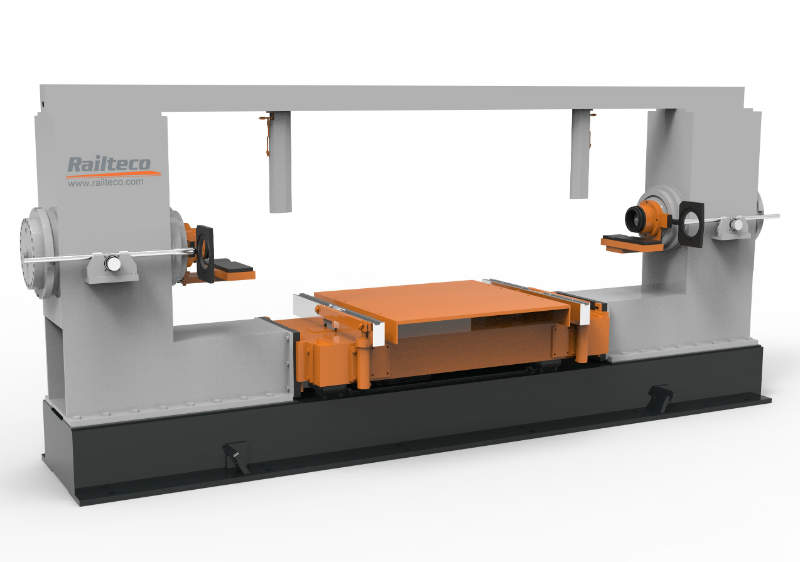

WY J2 Bearing Press-Fitting Machine is mainly used for non-axle box rolling bearing press fitting of railway EMU, passenger cars, light rails and metros.

It is controlled by a computer that can automatically generate press-fitting curve and can determine whether the result is qualified or not, the press-fitting process data can also be recorded automatically.

The main oil cylinder adopts double-cylinder compound cylinder structure. The internal cylinder is used for accurately positioning the bearing during press-fitting, and the external cylinder is for bearing press-fitting.

The entire press-fitting process is completed on the equipment axis. The press-fit cylinders are press-fit separately at both ends, synchronized and adjustable in speed.

Both ends can work independently, automatically or manually step-by-step. Provide Cloud-based remote data collection solutions to better serve users.

Main technical parameters include:

- Applicable gauge: 1,435mm

- Applicable axle length: 2,100mm-2,500mm

- Applicable wheel diameter: φ720mm-φ920mm

- Applicable bearing inner diameter: φ110mm-φ160mm

- Applicable work-piece weight: 2,500kg

- Maximum press force: 600kN

- Press-fitting beat: ≤5min/pair

- Equipment total power: 17.2kW

- Net weight: 6,500kg

- Overall dimension: 4,600mm×1,200mm×2,050mm